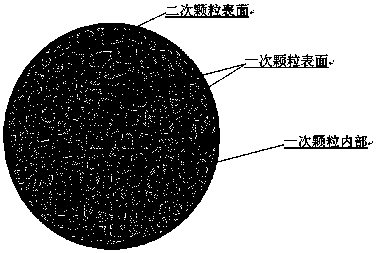

Multi-level cooperative modified lithium battery positive electrode material and preparation method thereof

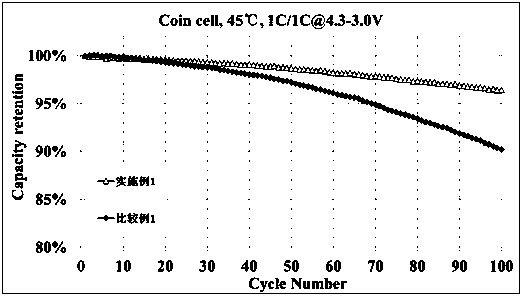

A cathode material, synergistic modification technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of loss of protective effect, neglect and deterioration of the coating layer, achieve excellent cycle characteristics and storage characteristics, and improve cycling and storage. Equal performance and the effect of reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the first step, the mixed aqueous solution of manganese sulfate, nickel sulfate and cobalt sulfate and the aqueous solution of magnesium sulfate are respectively passed into the In the continuous reaction kettle, a quantitative amount of sodium hydroxide solution and ammonia water are simultaneously passed through under the protection of nitrogen, and the reaction temperature is kept at 50° C., and precipitation is obtained by continuous overflow. Wash the obtained precipitate with water, filter and dry to obtain the hydroxide precursor Mn 0.295 Ni 0.500 co 0.200 Mg 0.005 (OH) 2 .

[0029] In the second step, the above precursor is mixed with lithium carbonate and molybdenum oxide at a molar ratio of 1:1.05:0.005, sintered at 950°C for 20 hours in an air atmosphere, naturally cooled, crushed, and sieved to obtain the composition Li 1.05 mn 0.295 Ni 0.500 co 0.200 Mg 0.005 Mo 0.005 o 2 powder.

[0030] The third step is to dry mix the obtained above-mentio...

Embodiment 2

[0032] Except for controlling the molar ratio of the second-step precursor to lithium carbonate and molybdenum oxide = 1:1.05:0.002, a positive electrode active material was obtained in the same manner as in Example 1 above.

Embodiment 3

[0034] The positive electrode active material was obtained in the same manner as in Example 1 above, except that the molar ratio of Al to the positive electrode material in the third step was controlled to be 0.01.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com