Turbine classifier as well as gradient classifying and purifying system for superfine silica powder

A turbine classifier and silicon dioxide technology, applied in swirl devices, grain processing, etc., can solve the problems of affecting the classification effect, reducing the classification accuracy, unreasonable structural design of the cage blade and guide blade, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

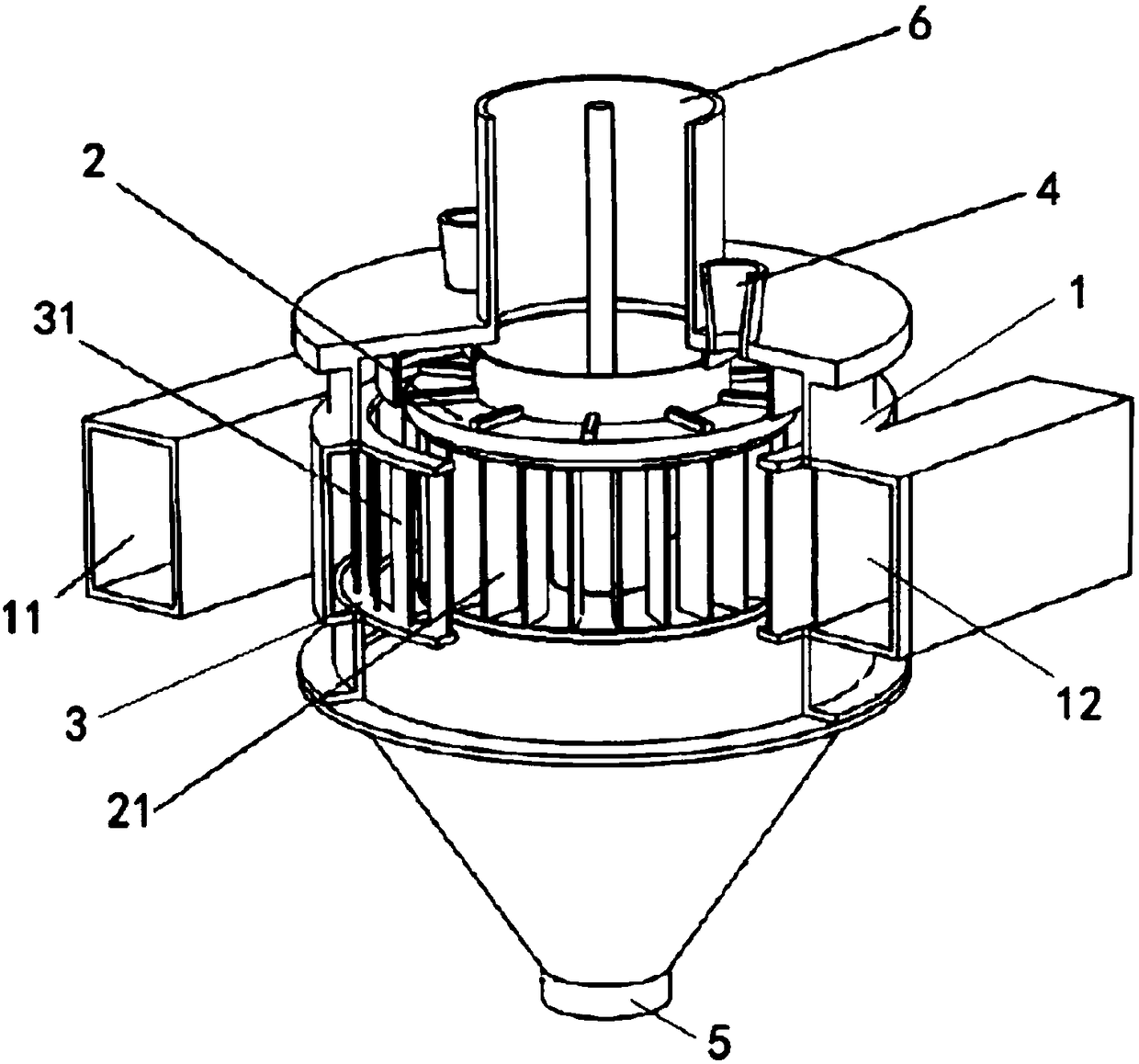

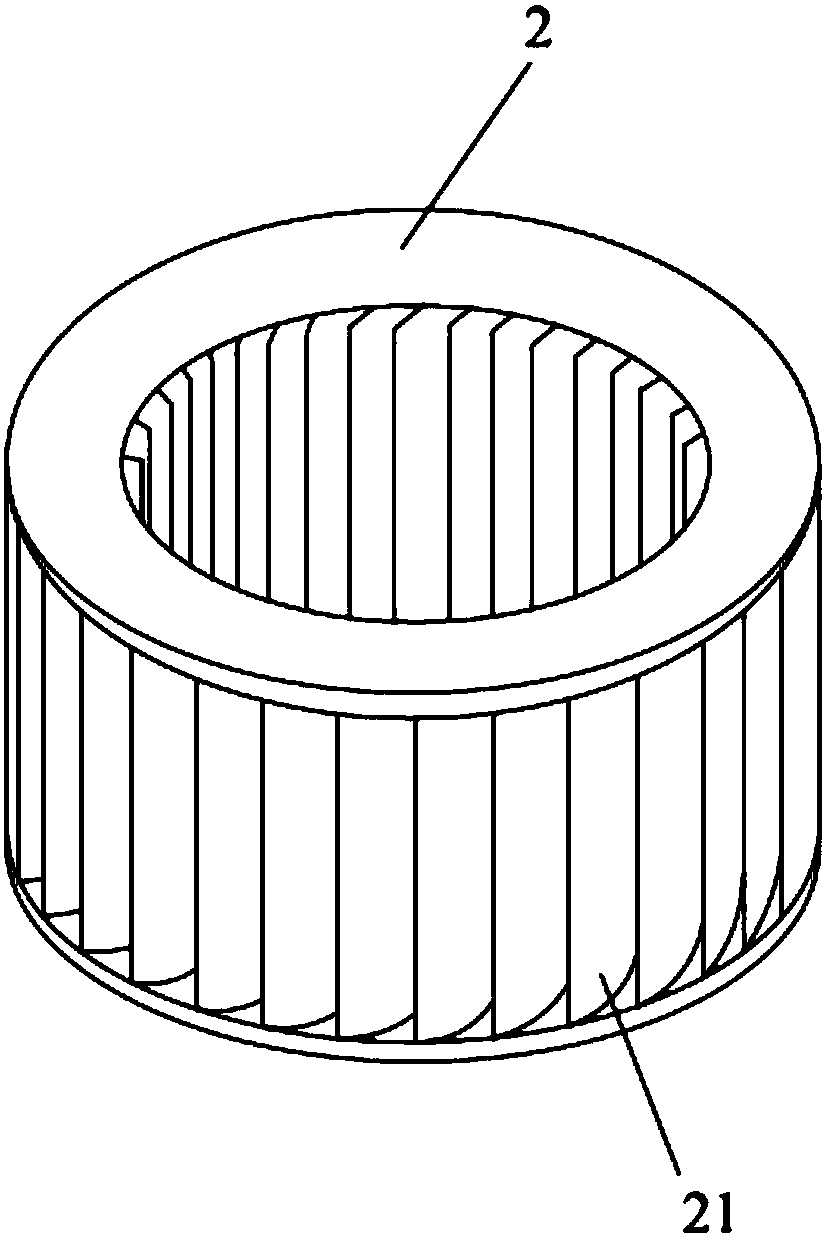

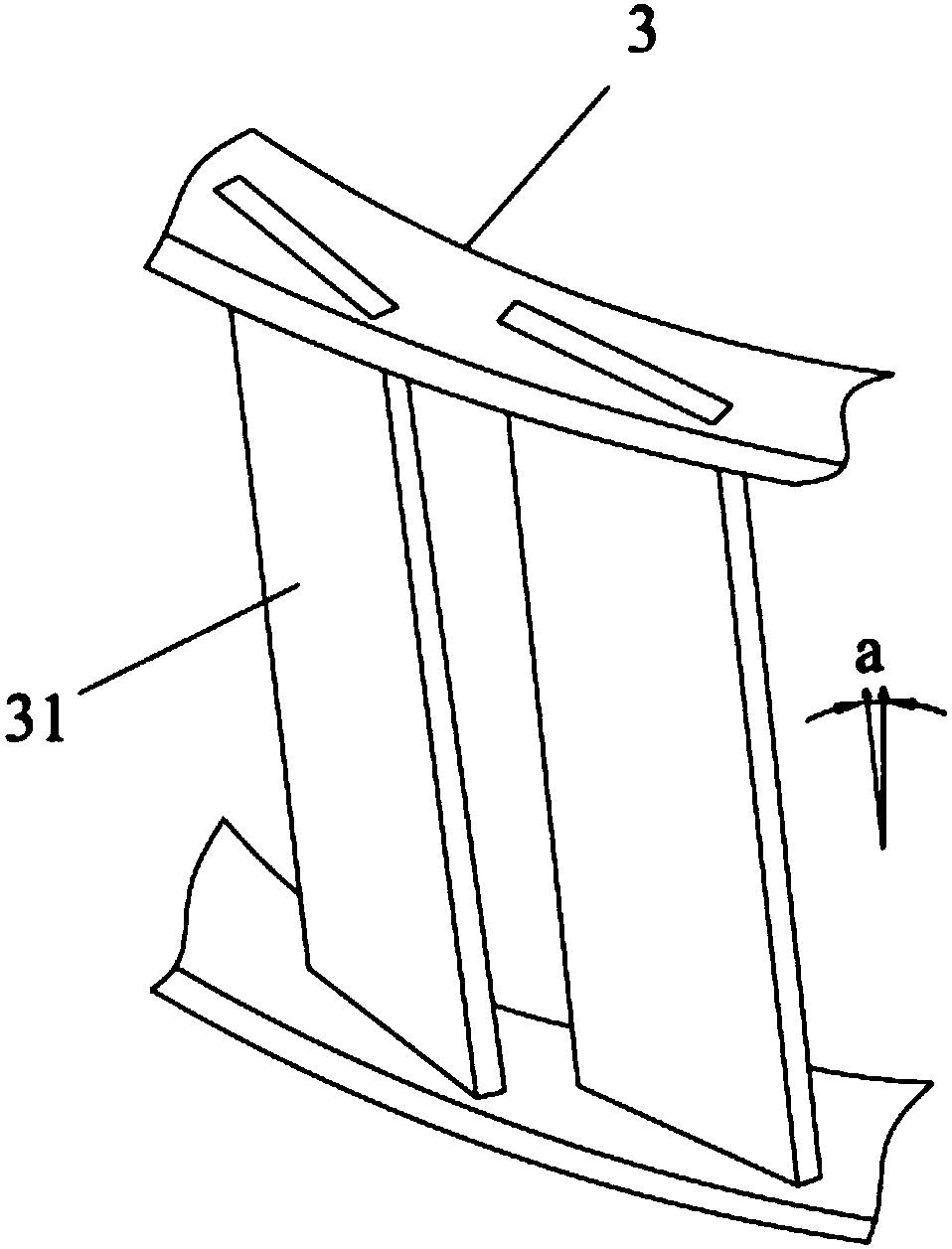

[0036] A turbo classifier, such as figure 1 As shown, it includes a spiral volute 1, a rotating cage 2 and a flow guiding mechanism 3 surrounding the rotating cage 2. Both ends of the volute 1 are provided with a first air inlet 11 and a second air inlet 12, and the rotating cage 2 includes several Two rotating cage blades 21 evenly distributed along the circumference of the rotating cage 2, the flow guiding mechanism 3 includes a number of guiding blades 31 evenly distributed around the rotating cage blades 21, and an annular separation channel is formed between the guiding blades 31 and the rotating cage blades 21 . The turbo classifier also includes a material inlet 4, a fine particle outlet 5 and a coarse particle outlet 6, and the coarse particle outlet 6 is in communication with the separation channel. When working, a certain fineness of silica powder enters the turbo classifier, the airflow enters the spiral volute 1 in the tangential direction, enters the annular separa...

Embodiment 2

[0044] A gradient graded purification system of ultrafine silica powder of this embodiment, such as Figure 4 As shown, it includes a ball mill 10, and also includes a multi-stage sorting device for crushing the silica powder output from the ball mill 10 and performing gradient separation step by step according to the particle fineness. The multi-stage sorting device includes two series arranged in series. A stage sorting unit, each stage sorting unit includes a turbo classifier 30 for centrifugally crushing a certain fineness of silica powder and separating coarse and fine particles, and a turbo classifier 30 for separating and collecting The output of the fine particles by the cyclone separator 40. That is, the first-stage sorting unit 201 includes a first-stage turbo classifier 30 and a first-stage cyclone 40, and the second-stage sorting unit 202 includes a second-stage turbo classifier 30 and a second-stage cyclone 40. The structures of all turbo classifiers 30 in this emb...

Embodiment 3

[0060] The main technical scheme of a gradient graded purification system for ultrafine silica powder of this embodiment is the same as that of embodiment 2, except that: Image 6 As shown, the multi-stage sorting device includes a three-stage sorting unit arranged in series, and the silica powder ground by a ball mill is sequentially sorted by the three-stage sorting unit: after being processed by the first-stage sorting unit Obtain first-level coarse particles and first-level fine particles, first-level fine particles are processed by the second-level sorting unit to obtain second-level coarse particles and second-level fine particles, and second-level fine particles are processed by the third-level sorting unit to obtain The third-level coarse particles and the third-level fine particles are high-purity ultrafine silica powder. After the processing of the above three-stage sorting unit, the product with a gradient grade of particle fineness can be accurately obtained. Because...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com