Preparation method of honeycomb shaped porous carbon spheres

A honeycomb, porous carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., to achieve the effects of low cost, simple preparation and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

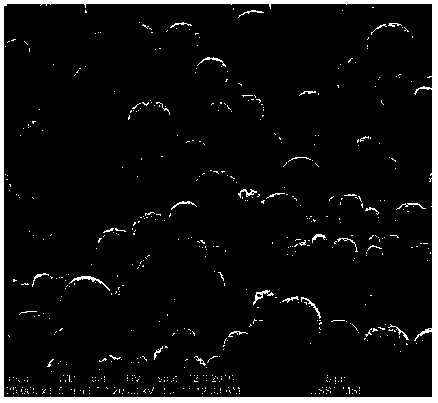

[0019] Take 100ml of 20g / l glucose solution and 2g of potassium hydroxide, mix them evenly, and then spray and dry them at 500°C. The collection device can collect the powder particles with a spherical structure. The collected powder particles were heat-treated at 800°C for 1 hour in an inert gas atmosphere, and then washed to obtain honeycomb porous carbon spheres with a specific surface area of 1068m 2 / g. The appearance of honeycomb porous carbon spheres is as follows: figure 1 shown.

Embodiment 2

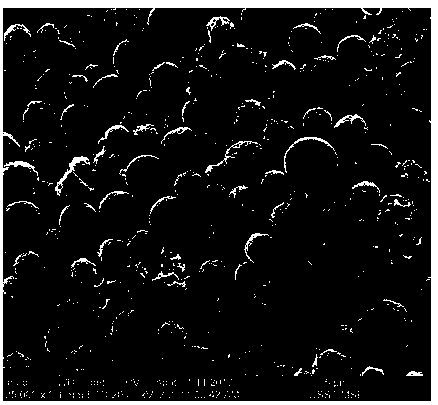

[0021] Take 100ml of 50g / l sucrose solution and 15g of sodium hydroxide, mix them evenly, and then spray and dry them at 600°C. The collection device can collect the powder particles with spherical structure. The collected powder particles were heat-treated at 900°C for 2 hours in an inert gas atmosphere, and then cleaned to obtain honeycomb porous carbon spheres with a specific surface area of 1652m 2 / g. The appearance of honeycomb porous carbon spheres is as follows: figure 2 shown.

Embodiment 3

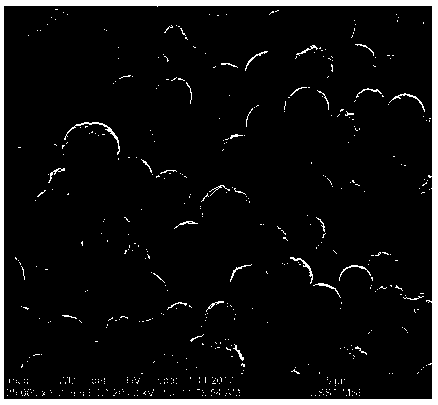

[0023] Take 100ml of 100g / l fructose solution and 50g of potassium carbonate, mix them evenly, and then spray and dry them at 300°C. The collection device can collect the powder particles with a spherical structure. The collected powder particles were heat-treated at 600° C. for 1 hour under an inert gas atmosphere, and then washed to obtain honeycomb porous carbon spheres. The appearance of honeycomb porous carbon spheres is as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com