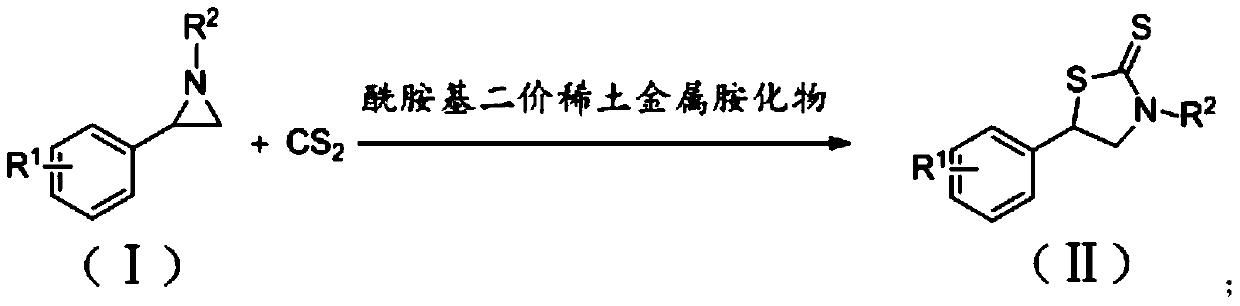

Preparation method of 3,5-disubstituted thiazolidine-2-thiones

A compound, thiazolidine technology, applied in the field of organic synthesis, can solve the problems of small expansion range of substrates, limited range of substrates, and large amount of catalysts, etc., to achieve simple separation and purification of products, wide applicability of reactants, and high catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

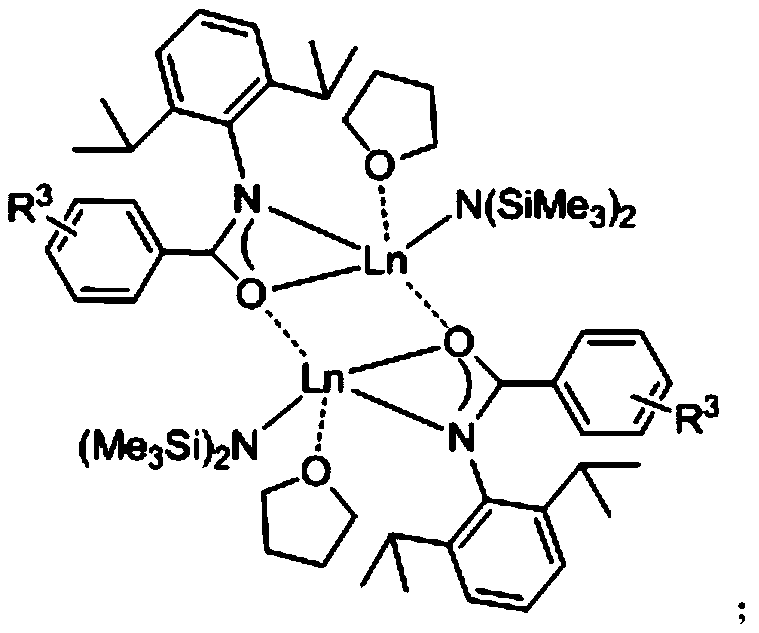

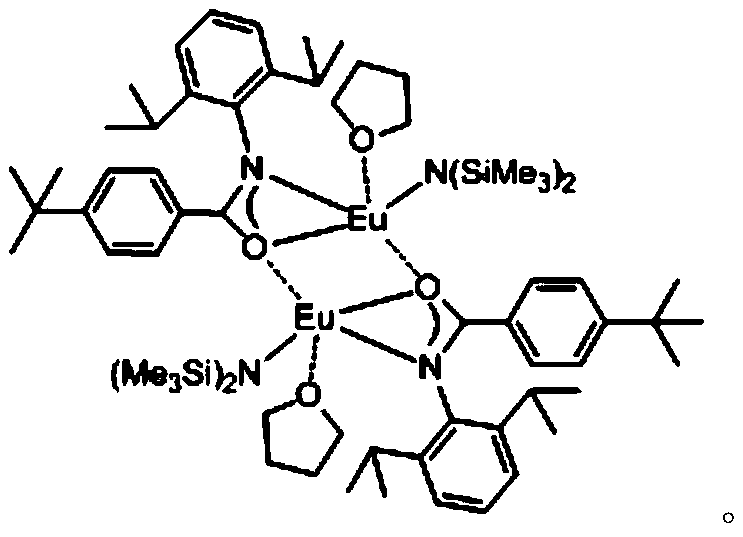

[0042] Example 1: 1mol% of {L 1 Eu[N(SiMe 3 ) 2 ]·THF} 2 Catalyzes the reaction of 2-phenyl-1-ethylcycloethyleneimine and carbon disulfide at 45°C:

[0043] Under the airtight conditions of anhydrous, oxygen-free and argon protection, add 0.0144g (1.00×10 -5 mole){L 1 Eu[N(SiMe 3 ) 2]·THF} 2 , then add 147μL (1.00×10 -3 mol) of 2-phenyl-1-ethylcycloethylimine was stirred at room temperature for 5 min under an argon atmosphere, and 300 μL (5.00×10 -3 mol) of carbon disulfide, stirred and reacted in a constant temperature bath at 45°C. After 24 hours, the protective argon gas was removed, and the reaction was quenched by air exposure. Column chromatography was performed using petroleum ether and ethyl acetate as developing solvents, and the solvent was spin-dried to obtain a separation yield of 90%. The structure of the target product is as follows:

[0044]

[0045] NMR data: 1 H NMR (400MHz, CDCl 3 ): δ7.31(s,5H),4.77(s,1H),4.31(s,1H),4.01(s,1H),3.80(s,2H),1.20...

Embodiment 2

[0047] Example 2: 1mol% of {L 1 Eu[N(SiMe 3 ) 2 ]·THF} 2 Catalyze the reaction of 2-phenyl-1-ethylcycloethyleneimine and carbon disulfide at 30°C:

[0048] Under the airtight conditions of anhydrous, oxygen-free and argon protection, add 0.0144g (1.00×10 -5 mole){L 1 Eu[N(SiMe 3 ) 2 ]·THF} 2 , then add 147μL (1.00×10 -3 mol) of 2-phenyl-1-ethylcycloethylimine was stirred at room temperature for 5 min under an argon atmosphere, and 300 μL (5.00×10 -3 mol) of carbon disulfide, stirred and reacted in a constant temperature bath at 30°C. After 24 hours, the protective argon gas was removed, and the reaction was quenched by air exposure. Column chromatography was performed using petroleum ether and ethyl acetate as developing solvents, and the solvent was spin-dried to obtain a separation yield of 72%.

Embodiment 3

[0049] Example 3: 1mol% of {L 1 Eu[N(SiMe 3 ) 2 ]·THF} 2 Catalyzes the reaction of 2-phenyl-1-ethylcycloethyleneimine and carbon disulfide at 40°C:

[0050] Under the airtight conditions of anhydrous, oxygen-free and argon protection, add 0.0144g (1.00×10 -5 mole){L 1 Eu[N(SiMe 3 ) 2 ]·THF} 2 , then add 147μL (1.00×10 -3 mol) of 2-phenyl-1-ethylcycloethylimine was stirred at room temperature for 5 min under an argon atmosphere, and 300 μL (5.00×10 -3 mol) of carbon disulfide, stirred and reacted in a constant temperature bath at 40°C. After 24 hours, the protective argon gas was removed, and the reaction was quenched by air exposure. Column chromatography was performed with petroleum ether and ethyl acetate as developing solvents, and the solvent was spin-dried to obtain a separation yield of 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com