Method for preparing inorganic crystal whisker/POSS (Polyhedral Oligomeric Silsesquioxane) hybrid material by utilizing sulfydryl-alkene click reaction

A technology of inorganic whiskers and hybrid materials, applied in the direction of coating, etc., to achieve the effects of high grafting efficiency, high yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

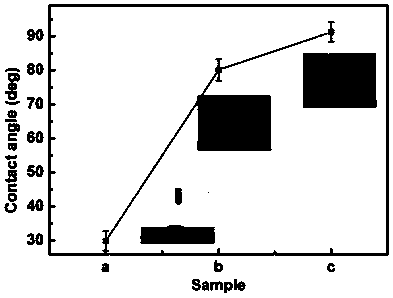

Embodiment 1

[0042] Step 1: Surface mercaptolation of inorganic whiskers

[0043] 0.5g of KH590, deionized water, and absolute ethanol were used to form a mixed solvent with a volume ratio of 1:1:4, and the pH was adjusted to 3-5 with acetic acid, and hydrolyzed at room temperature for 2 hours. 3g basic magnesium sulfate whisker is placed in three-necked flask after ultrasonic dispersion 3min in the mixed solution of absolute ethanol, deionized water (70ml of absolute ethanol, 10ml of deionized water), reflux heating reaction in oil bath. The hydrolyzate was added dropwise, the reaction temperature was controlled at 70° C., and the reaction time was 4 hours. After the reaction, wash with ethanol for 3 to 4 times to remove ungrafted KH590, and dry in a vacuum oven at 70°C for 24 hours to obtain basic magnesium sulfate whiskers with mercaptolation on the surface.

[0044] Step 2: Thiol-ene click reaction

[0045] Dissolve 0.2g of octavinyl POSS and 0.02g of benzoin dimethyl ether in 5ml of...

Embodiment 2

[0048] Step 1: Surface mercaptolation of inorganic whiskers

[0049] 5g of KH590, deionized water, and absolute ethanol were mixed in a volume ratio of 1:1:4, adjusted to pH 3-5 with acetic acid, and hydrolyzed at room temperature for 2 hours. 3g basic magnesium sulfate whisker is placed in three-necked flask after ultrasonic dispersion 3min in the mixed solution of absolute ethanol, deionized water (70ml of absolute ethanol, 10ml of deionized water), reflux heating reaction in oil bath. The hydrolyzate was added dropwise, the reaction temperature was controlled at 70° C., and the reaction time was 4 hours. After the reaction, wash with ethanol for 3 to 4 times to remove ungrafted KH590, and dry in a vacuum oven at 70°C for 24 hours to obtain basic magnesium sulfate whiskers with mercaptolation on the surface.

[0050] Step 2: Thiol-ene click reaction

[0051] Dissolve 0.2g of octavinyl POSS and 0.02g of benzoin dimethyl ether in 5ml of tetrahydrofuran, add 0.5g of mercapto ...

Embodiment 3

[0053] Step 1: Surface mercaptolation of inorganic whiskers

[0054] 0.3g of KH590, deionized water, and absolute ethanol were used to form a mixed solvent with a volume ratio of 1:1:4, and the pH was adjusted to 3-5 with acetic acid, and hydrolyzed at room temperature for 2 hours. 3g basic magnesium sulfate whisker is placed in three-necked flask after ultrasonic dispersion 3min in the mixed solution of absolute ethanol, deionized water (70ml of absolute ethanol, 10ml of deionized water), reflux heating reaction in oil bath. The hydrolyzate was added dropwise, the reaction temperature was controlled at 90°C, and the reaction time was 2h. After the reaction, wash with ethanol for 3 to 4 times to remove ungrafted KH590, and dry in a vacuum oven at 70°C for 24 hours to obtain basic magnesium sulfate whiskers with mercaptolation on the surface.

[0055] Step 2: Thiol-ene click reaction

[0056] Dissolve 0.2g of octavinyl POSS and 0.02g of benzoin dimethyl ether in 5ml of tetrah...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com