Aqueous zinc plating sealing agent and preparation method thereof

A sealing agent, water-based technology, applied in the field of water-based galvanized sealing agent and its preparation, can solve the problems of inhomogeneity and discoloration, corrosion resistance, uneven anti-corrosion coating, weak adhesion, etc., to maintain chemical balance, improve Adhesion and weather resistance, effect of delaying oxidation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

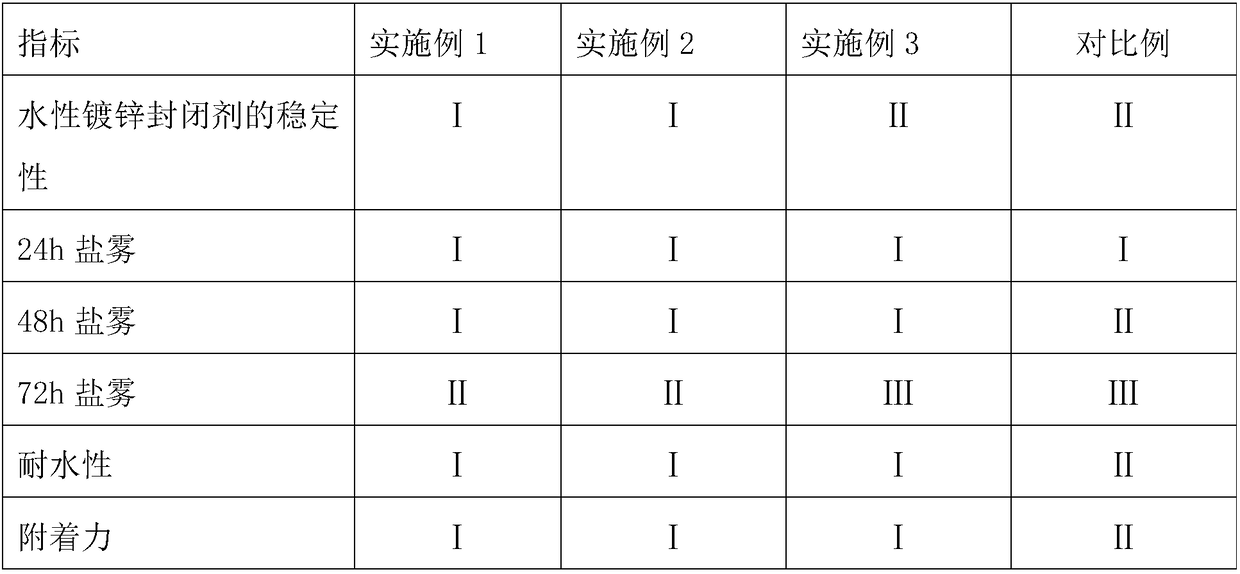

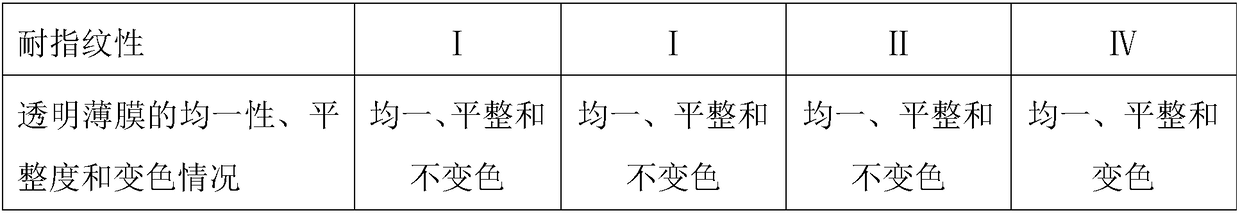

Embodiment 1

[0030] A water-based galvanized sealant, including the following raw materials: 30kg sodium silicate, 6kg polymethylacrylate, 3kg defoamer, 1kg coupling agent, 3kg phosphite antioxidant, 10kg sodium nitrite, fat Alcohol polyoxyethylene ether 3kg, film forming agent 4kg, stabilizer 1kg and water 100kg.

[0031] The defoamer is a mixture of emulsified silicone oil, polyoxyethylene polyoxypropanolamine ether, polyoxypropylene glyceryl ether and polydimethylsiloxane.

[0032] The coupling agent is a mixture of silane coupling agent, titanate coupling agent and zirconium coupling agent.

[0033] The phosphite antioxidant is bis(2,4-dicumylphenyl)pentaerythritol diphosphite.

[0034] The film former is a mixture of waterborne polyurethane, cationic polyacrylamide and polyvinylpyrrolidone.

[0035] The stabilizer is a mixture of sodium dihydrogen phosphate, disodium hydrogen phosphate and sodium phosphate.

[0036] The water-based galvanized sealer also includes a toughening agent...

Embodiment 2

[0046] A water-based galvanized sealant, including the following raw materials: 40kg sodium silicate, 10kg polymethylacrylate, 7kg defoamer, 5kg coupling agent, 5kg phosphite antioxidant, 14kg sodium nitrite, fat Alcohol polyoxyethylene ether 9kg, film forming agent 6kg, stabilizer 3kg and water 100kg.

[0047] The defoamer is emulsified silicone oil.

[0048] The coupling agent is a silane coupling agent.

[0049] The phosphite antioxidant is distearyl pentaerythritol diphosphite.

[0050] The film former is waterborne polyurethane.

[0051] The stabilizer is sodium dihydrogen phosphate.

[0052] The water-based galvanized sealer also includes a toughening agent weighing 3 kg.

[0053] The toughening agent is liquid silicone rubber.

[0054] A preparation method of water-based galvanized sealant, comprising the following steps:

[0055] (1) take raw material according to the weight of water-based galvanized sealing agent raw material;

[0056] (2) Add sodium silicate i...

Embodiment 3

[0062] A water-based galvanized sealant, including the following raw materials: 35kg sodium silicate, 8kg polymethylacrylate, 5kg defoamer, 3kg coupling agent, 4kg phosphite antioxidant, 12kg sodium nitrite, fat Alcohol polyoxyethylene ether 6kg, film forming agent 5kg, stabilizer 2kg and water 100kg.

[0063] The antifoaming agent is polyoxypropylene glyceryl ether.

[0064] The coupling agent is a titanate coupling agent.

[0065] The phosphite antioxidant is tris(nonylphenyl)phosphite.

[0066] The film former is polyvinylpyrrolidone.

[0067] The stabilizer is sodium phosphate.

[0068] The water-based galvanized sealer also includes a toughening agent weighing 2 kg.

[0069] The toughening agent is polysulfide rubber.

[0070] A preparation method of water-based galvanized sealant, comprising the following steps:

[0071] (1) take raw material according to the weight of water-based galvanized sealing agent raw material;

[0072] (2) Add sodium silicate into 80kg of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com