Waste bacteria treatment method and waste bacteria recycling method in waste bacterial production

A treatment method, the technology of spiramycin, is applied in the direction of microorganism-based methods, biochemical equipment and methods, and the dissolution of microorganisms, which can solve the problem of increased burden on enterprises, secondary environmental pollution, environmental cycles of antibiotics or analogues that cannot be ruled out, etc. problems, to achieve the effect of avoiding outflow and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take 50 L of the fermented spiramycin production broth after fermentation, adjust the pH to 5.5 with hydrochloric acid, and filter using the ceramic membrane filtration system of Nanjing Jiuwu Company. The diameter of the ceramic membrane filter element is 25 nm. After filtration, 35 L of concentrated solution intercepted by the ceramic membrane was obtained.

[0030] Transfer the concentrate to the reaction kettle, heat up to 35°C, add lysozyme (Zhejiang Aijiesi Biotechnology Co., Ltd.) 4 × 10 7 U, reacted for 3 hours; the temperature of the reaction solution was raised to 55°C, and the unit enzyme activity was added to be 5×10 4 Alkaline protease 20g (Shandong Sukehan Biological Engineering Co., Ltd.) of U / g reacted for 6 hours; Advance into spray drying (Shanghai Dacheng Experimental Equipment Co., Ltd.) to obtain waste bacteria powder 4.2kg, wherein moisture 11.5%.

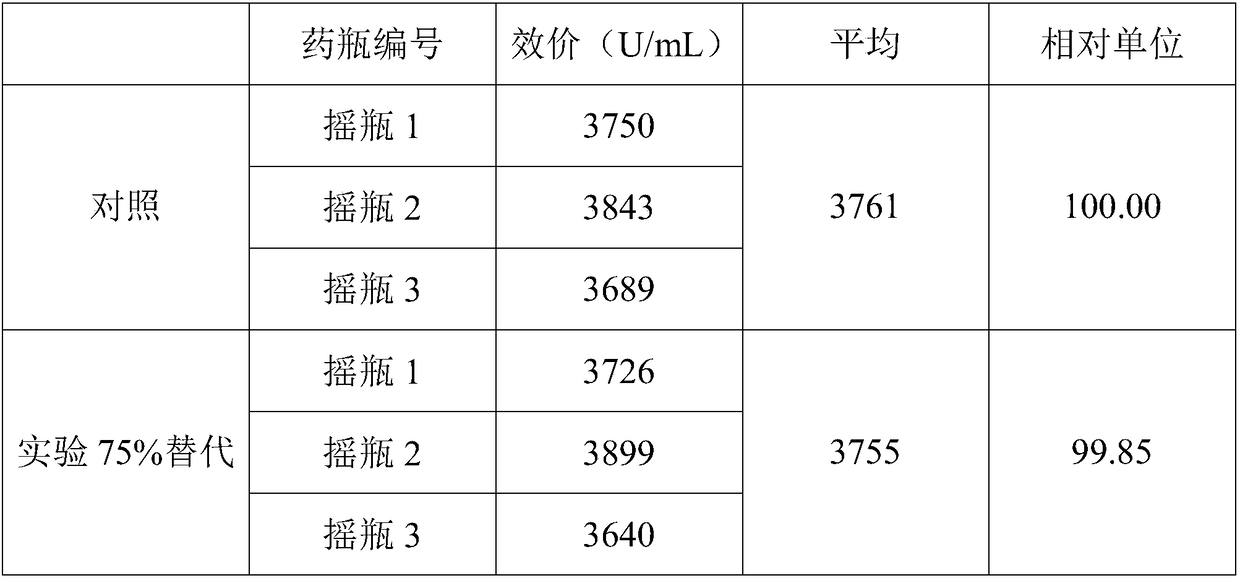

[0031] Use the obtained waste bacteria powder to replace 75% of the total amount of soybean cake po...

Embodiment 2

[0035] Take 50L of the fermented spiramycin production broth that has finished fermentation, adjust the pH to 4.9 with hydrochloric acid, and filter using the ceramic membrane filtration system of Nanjing Jiuwu Company. The diameter of the ceramic membrane filter element is 50nm. After filtration, 32L of concentrated solution was obtained.

[0036] Transfer the concentrate to the reaction kettle, heat up to 30°C, add lysozyme (Zhejiang Aijiesi Biotechnology Co., Ltd.) 4 × 10 7 U, reacted for 5 hours; the temperature of the reaction solution was raised to 65°C, and the unit enzyme activity was added to be 5×10 4 Alkaline protease 20g (Shandong Sukehan Biological Engineering Co., Ltd.) of U / g was reacted for 8 hours; Advance into spray drying (Shanghai Dacheng Experimental Equipment Co., Ltd.) to obtain waste bacteria powder 3.9kg, moisture 10.7%.

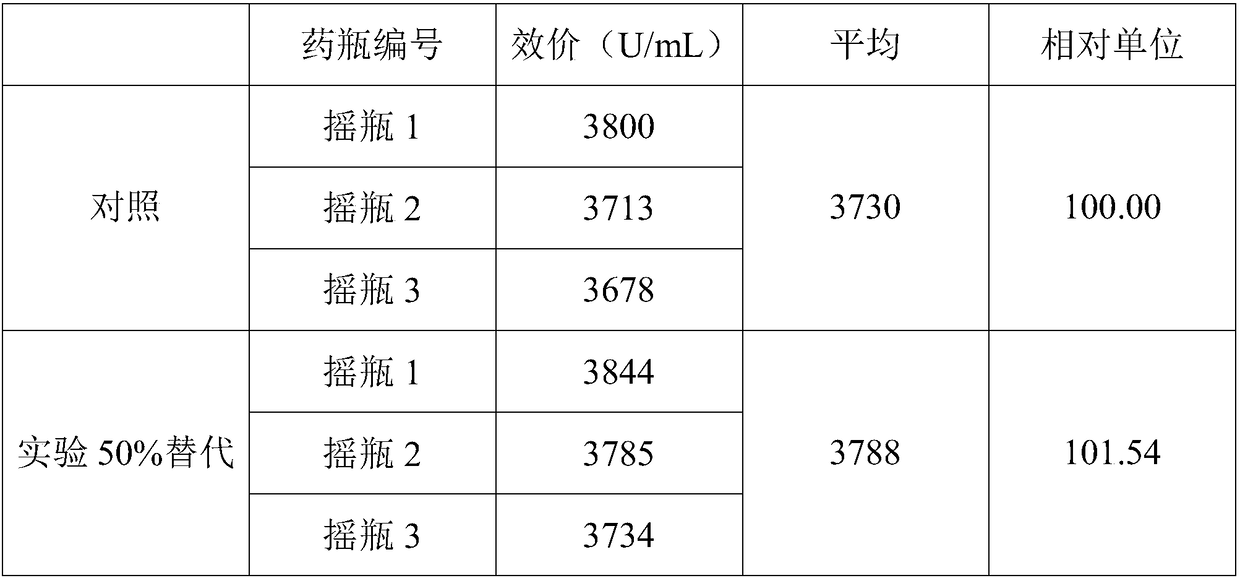

[0037] The obtained waste bacteria powder was used to replace the soybean cake powder in the original fermentation base material i...

Embodiment 3

[0041] Take 50L of the fermented spiramycin production broth after fermentation, adjust the pH to 6.5 with hydrochloric acid, and filter using the ceramic membrane filtration system of Nanjing Jiuwu Company. The diameter of the ceramic membrane filter element is 25nm. After filtration, 34L of concentrated solution was obtained.

[0042] Transfer the concentrate to the reaction kettle, heat up to 35°C, add lysozyme (Zhejiang Aijiesi Biotechnology Co., Ltd.) 4 × 10 7 U, reacted for 4 hours; the reaction solution was warming up to 60°C, added 20g of neutral protease (Shandong Sukehan Biological Engineering Co., Ltd.), and reacted for 6 hours; into spray drying (Shanghai Dacheng Experimental Equipment Co., Ltd.) to obtain waste Bacteria powder 3.8kg, moisture 10.3%.

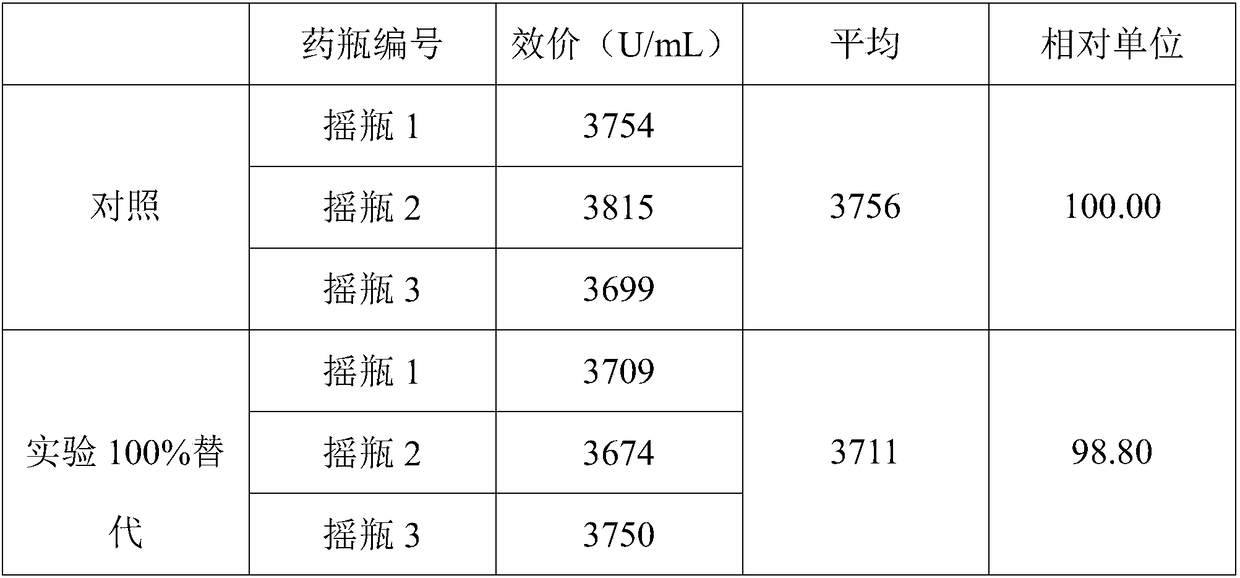

[0043] The obtained waste bacteria powder was used to replace the soybean cake powder in the original fermentation base material in a proportion of 100% for shake-flask fermentation, and the original fermentation ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com