High-temperature sewage waste heat recovery and high-efficiency reutilization process

A high-temperature sewage and waste heat technology, applied in degassed water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of flue gas emission, large gas or fuel consumption, and discharge, etc. problems, to achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

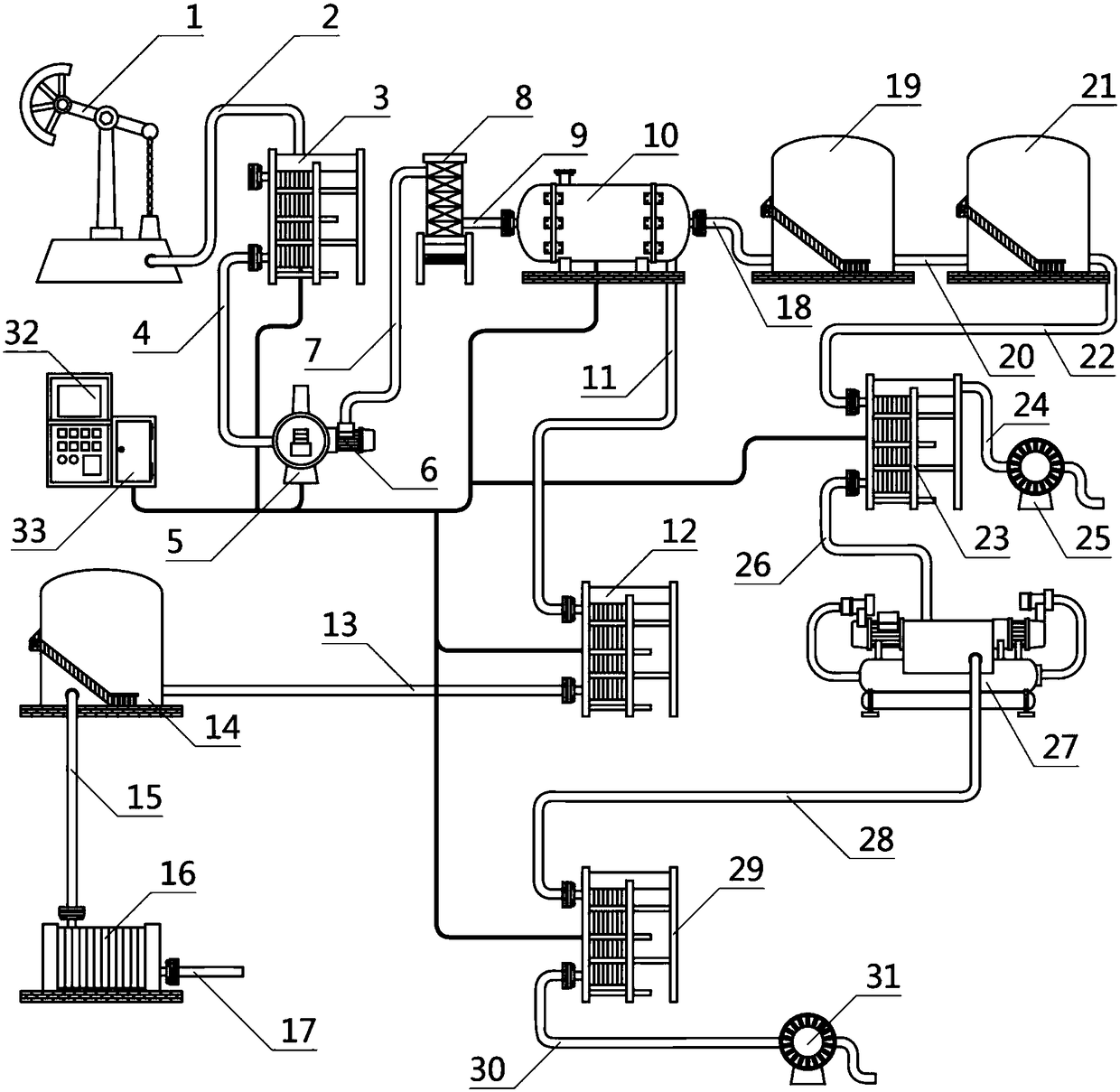

[0027] The specific embodiments of the present invention will be briefly described below in conjunction with the drawings.

[0028] Such as figure 1 A process for recovering waste heat from high-temperature sewage and high-efficiency reuse is shown, which is characterized by: oil well 1, dehydration heat exchanger 3, heating furnace 5, filter 8, three-phase separator 10, and primary heat exchanger 12 , Buffer tank 14, water injection device 16, sedimentation tank 19, oil storage tank 21, secondary heat exchanger 23, ultra-high temperature heat pump 27, tertiary heat exchanger 29 and controller 32, the oil well 1 is also provided with The oil well inflow output pipe 2 is located on one side of the oil well 1, one end of the oil well inflow output pipe 2 is fixedly connected to the oil well 1, and the other end of the oil well inflow output pipe 2 It is fixedly connected to the dehydration heat exchanger 3, the dehydration heat exchanger 3 is located at one side of the oil well in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com