Preparation method for nitrogen-doped carbon dot/graphene oxide nanocomposite electrocatalyst

A nitrogen-doped carbon dot and nanocomposite technology, applied in nanotechnology, circuits, electrical components, etc., can solve problems affecting the performance and service life of fuel cells, slow kinetic process, poor stability, etc., to achieve strong The effect of oxygen reduction electrocatalytic performance, good stability and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

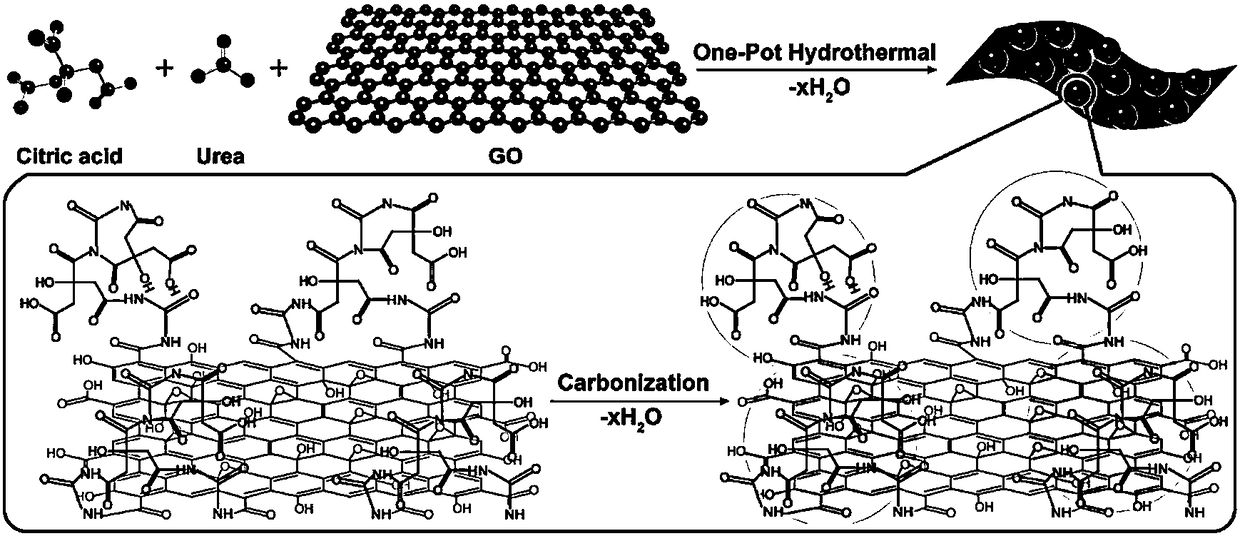

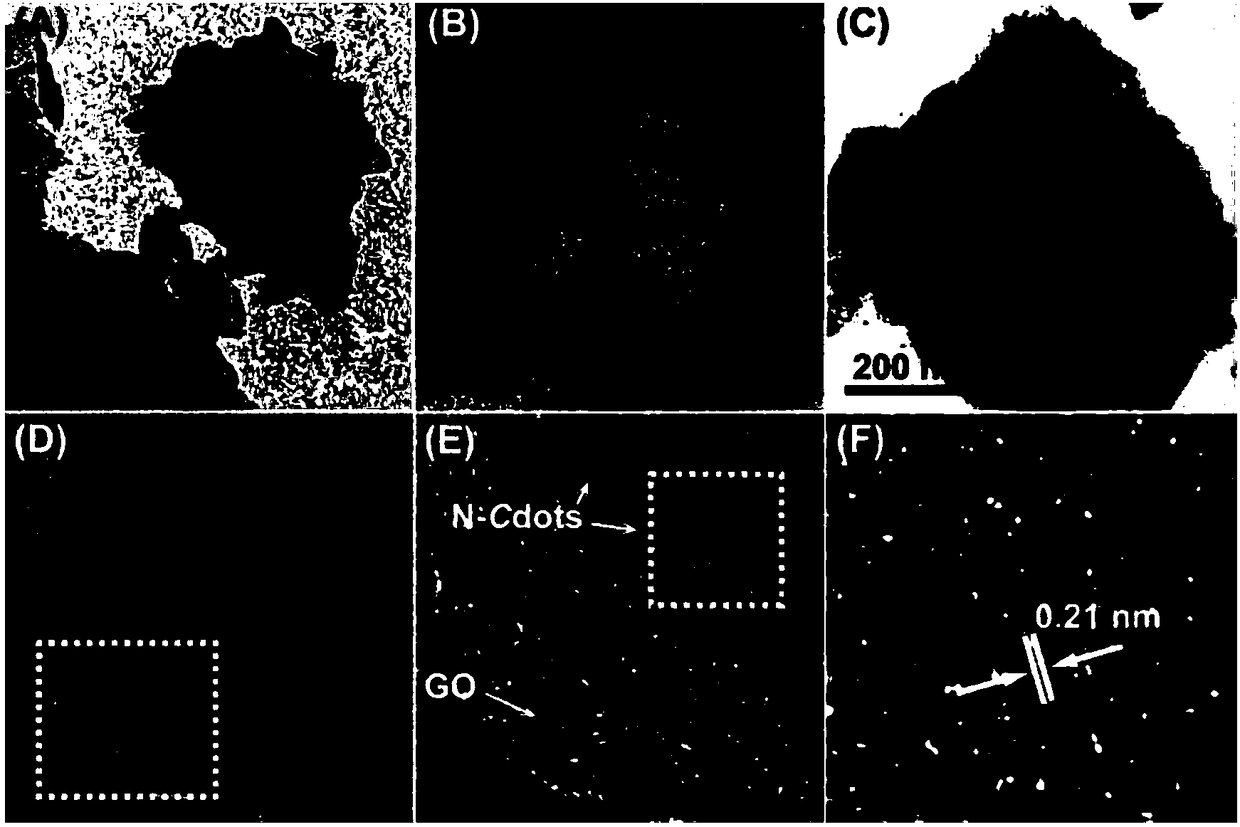

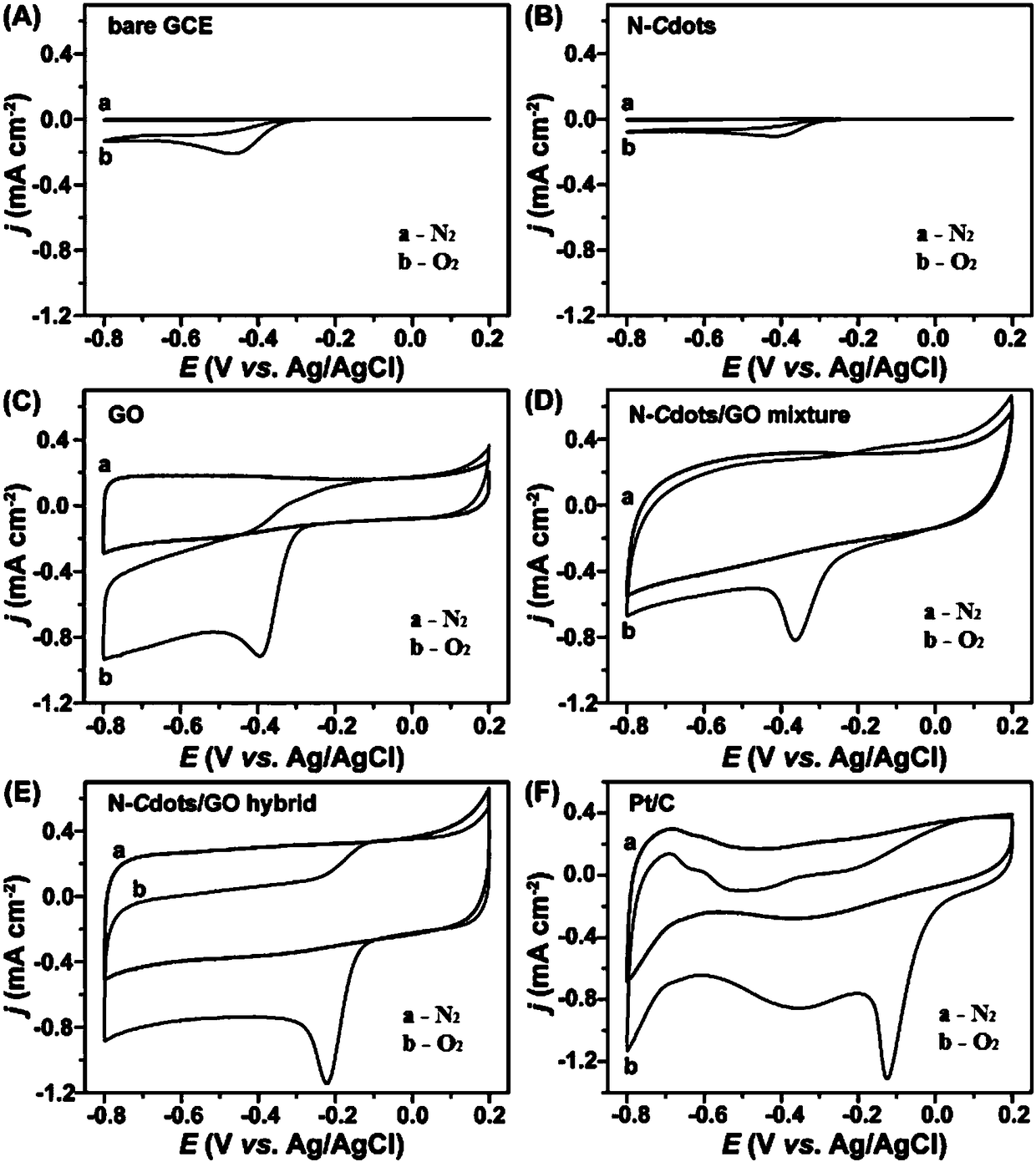

[0025] A preparation method for preparing nitrogen-doped carbon dots / graphene oxide (N-Cdots / GO) nanocomposite electrocatalyst of the present invention, such as figure 1 , including the following steps:

[0026] Step 1. Weigh 2.673g of citric acid, 0.90g of urea and 0.05g of graphene oxide, dissolve them in 30.0mL of ultrapure water in turn, put them into an ultrasonic instrument and sonicate until they are evenly dispersed;

[0027] Step 2. Transfer the above mixed solution to a 50mL polytetrafluoroethylene-lined stainless steel autoclave, place it in a blast heating oven, and conduct a hydrothermal reaction at 180°C for 12 hours;

[0028] Step 3, after the reaction is finished, cool down to room temperature naturally to obtain a dark brown liquid;

[0029] Step 4, use a high-speed centrifuge to remove impurities such as excess citric acid at a speed of 10000rmp for 10 minutes;

[0030] Step 5. The centrifuged sample was placed in a vacuum drying oven at 50° C. for 24 hours...

Embodiment 2

[0032] A method for preparing nitrogen-doped carbon dots (N-Cdots) for comparison with N-Cdots / GO of the present invention, the only difference between Example 2 and Example 1 is that graphite oxide is not used in the synthesis process alkenes as templates.

Embodiment 3

[0034] A method for preparing a nitrogen-doped carbon dot / graphene oxide mixture that is compared with N-Cdots / GO of the present invention is by directly mixing an appropriate amount of nitrogen-doped carbon dots prepared in Example 2 with graphene oxide get.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Faraday constant | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com