Plant polysaccharide heat insulation aerogel material and preparation method

A thermal insulation and aerogel technology, which is applied to the preparation of konjac polysaccharide thermal insulation aerogel and the field of konjac polysaccharide thermal insulation aerogel, can solve the problems of environmental pollution, pollute the environment, easy to burn, etc. The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

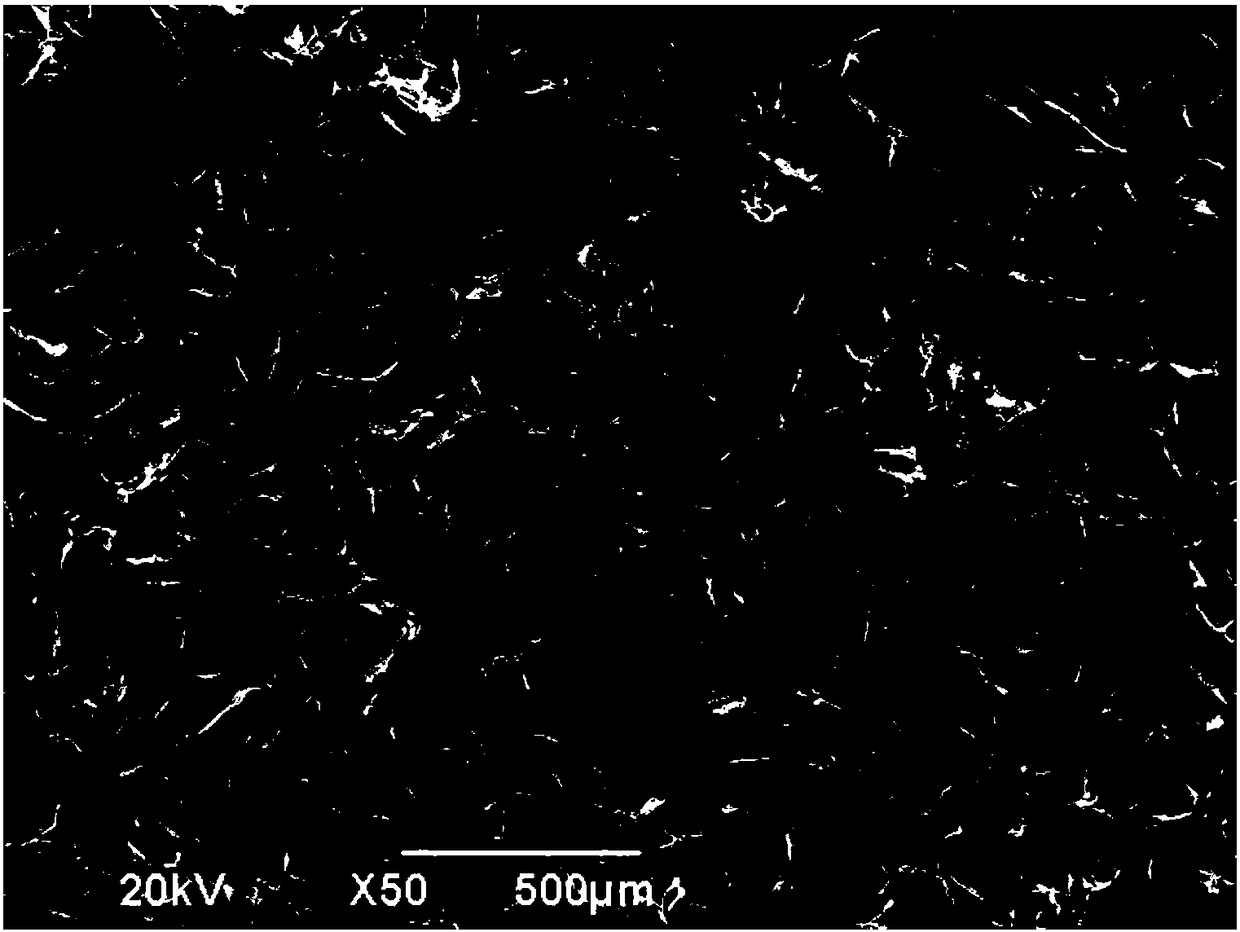

Image

Examples

Embodiment 1

[0052] A kind of konjac polysaccharide thermal insulation aerogel, it is made of the raw material of following weight or volume:

[0053]

[0054]

[0055] A method for preparing konjac polysaccharide thermal insulation airgel, characterized in that it is prepared according to the following steps:

[0056] (1) Chitosan was dissolved in 50mL 1v / v% acetic acid solution, stirred at room temperature for 30min to obtain solution A;

[0057] (2) Take a certain amount of deionized water and add glycerin, under the condition of mechanical stirring at 800rpm, then add starch, konjac glucomannan, auxiliary glue, straw, nano-calcium carbonate, and stir quickly to obtain solution B;

[0058] (3) Mix solution A and solution B to obtain solution C, and stir solution C at 60°C for 3.5 hours to obtain a transparent viscous gel;

[0059] (4) Pour the stirred transparent viscous gel homogeneously into a mold and cool it into a gel;

[0060] (5) Pre-freezing at -30°C for 24 hours;

[00...

Embodiment 2-8

[0062] Embodiment 2-8: According to the raw material components in Table 1, according to the process parameters in Table 2, the preparation steps are the same as those in Example 1. The performance indexes of the prepared konjac polysaccharide thermal insulation airgel are shown in Table 3.

[0063] Table 1: The raw material composition table of embodiment

[0064]

[0065]

[0066] Table 2. Process parameter list

[0067]

Example 2

Example 3

Example 4

Example 5

Example 6

Example 7

Example 8

Solution A stirring time (min)

45

30

35

55

50

60

30

speed(rpm)

700

600

800

900

1200

1500

400

Stirring temperature of solution C (°C)

75

70

75

80

85

90

60

Solution C stirring time (h)

0.8

0.5

1

1.5

2.5

3

0.5

Pre-freezing temperature (℃)

-15

-10

-20

-25

-45

-60

-12

Pre-freezing time (h)

8

6

10

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com