Preparation method of sulfide-graphene composite material photoelectric catalyst

A composite material, graphene technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of poor conductivity, easy self-aggregation, etc., to improve catalytic activity, inhibit self-stacking, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

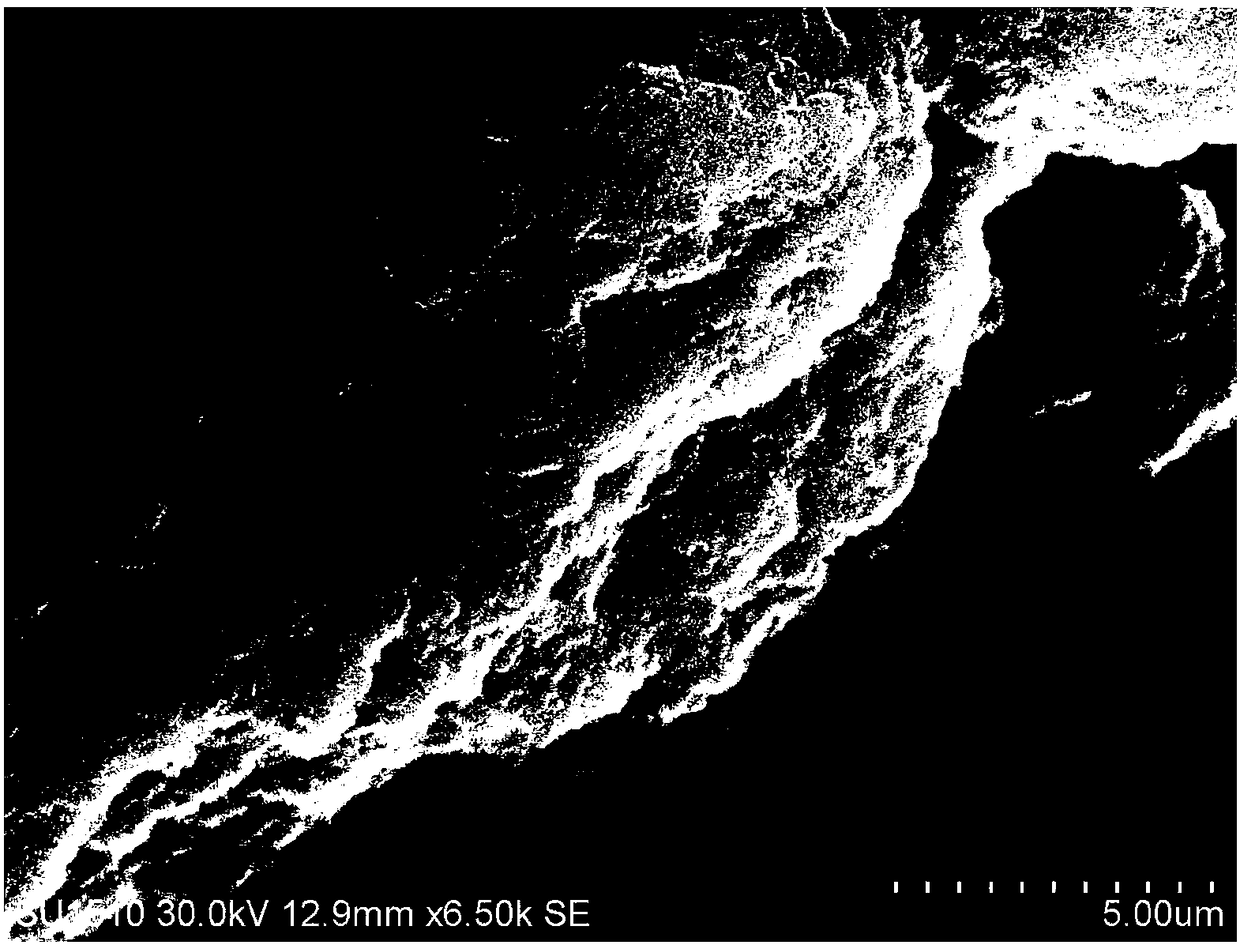

[0020] In this example, see figure 1 , a kind of preparation method of sulfide-graphene composite material photocatalyst, comprises the steps:

[0021] (1) Dissolve 1g of graphene oxide in 1000mL of deionized water and ultrasonically disperse to obtain a graphene oxide dispersion; dissolve 1g of cupric chloride dihydrate soluble metal salt in the above dispersion, fully stir for 1h and then let it stand Graphene oxide-copper chloride mixed solution, remove the precipitate and wash once, put it in a vacuum oven for drying at 45°C, and then grind it into powder to obtain graphene oxide powder doped with metal copper ions;

[0022] (2) ultrasonically disperse the copper ion-doped graphene oxide powder prepared in the step (1) in 100mL deionized water, then add 2g of molybdenum-containing sodium molybdate solution, and stir the mixed solution for 1h, Add 4 g of thiourea ((NH 2 ) 2 CS) to make a mixed solution of reactants, then transfer the mixed solution of reactants to a poly...

Embodiment 2

[0027] This embodiment is basically the same as Embodiment 1, especially in that:

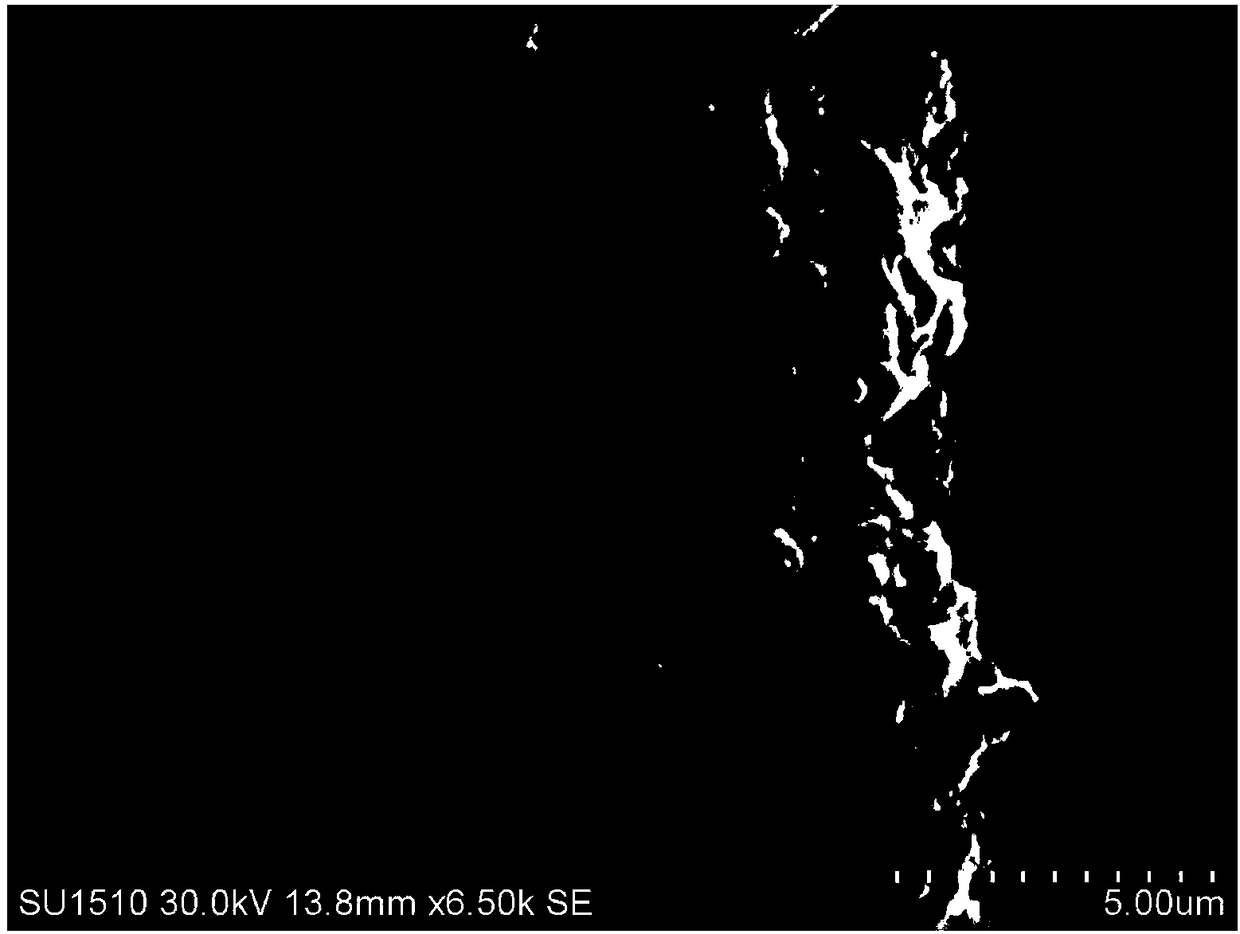

[0028] In this example, see figure 2 , a kind of preparation method of sulfide-graphene composite material photocatalyst, comprises the steps:

[0029] (1) Dissolve 1g of graphene oxide in 1000mL of deionized water and ultrasonically disperse to obtain a graphene oxide dispersion; dissolve 1g of zinc chloride dihydrate soluble metal salt in the above dispersion, fully stir for 1h and then let it stand Graphene oxide-zinc chloride mixed solution, remove the precipitate and wash once, put it in a vacuum oven for drying at 45°C, and then grind it into powder to obtain graphene oxide powder doped with metal zinc ions;

[0030] (2) ultrasonically disperse the zinc ion-doped graphene oxide powder prepared in the step (1) in 100mL deionized water, then add 2g of molybdenum-containing sodium molybdate solution, and stir the mixed solution for 1h, After fully mixing, add 4g of thiourea to prepare a r...

Embodiment 3

[0035] This embodiment is basically the same as the previous embodiment, and the special features are:

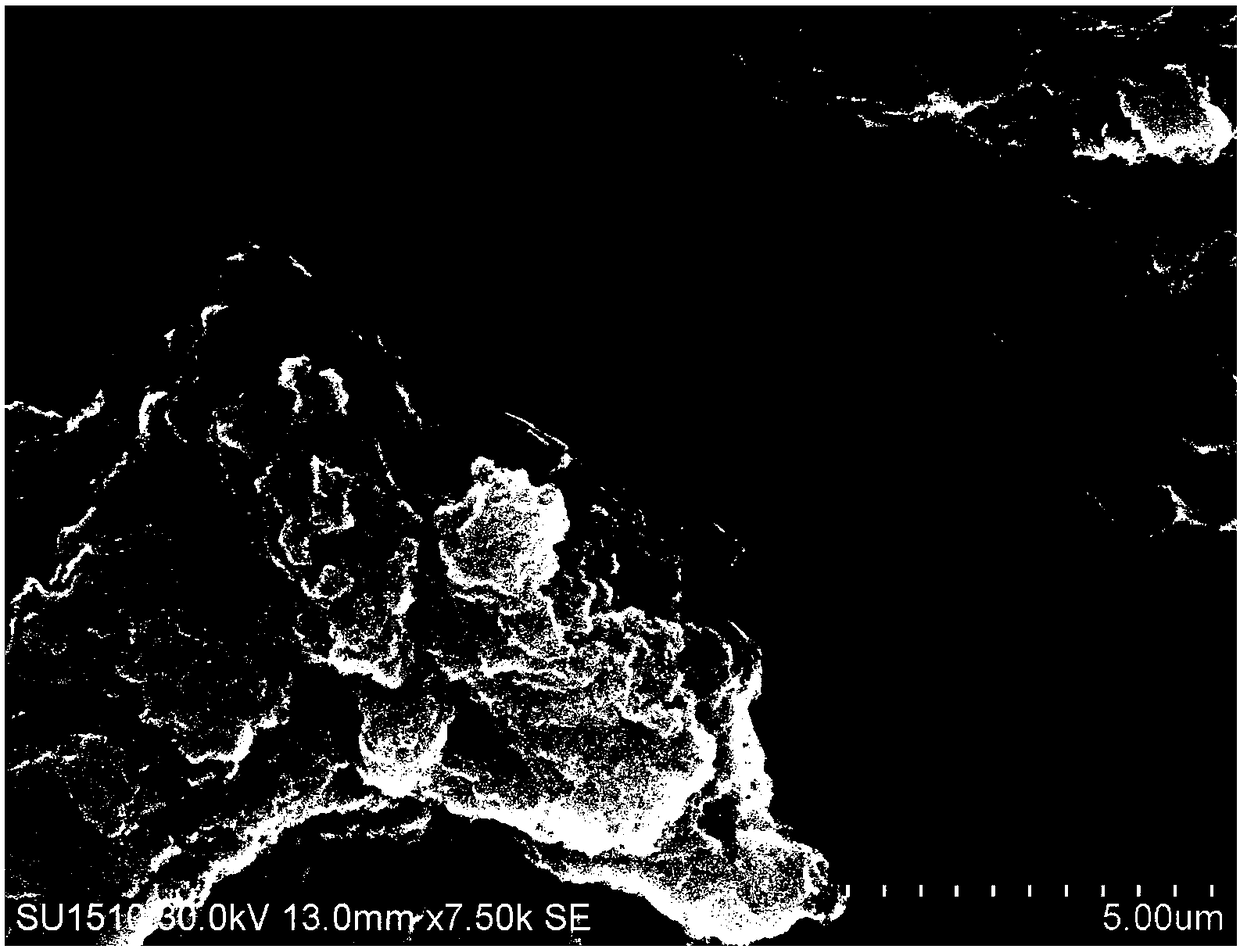

[0036] In this example, see image 3 , a kind of preparation method of sulfide-graphene composite material photocatalyst, comprises the steps:

[0037] (1) Dissolve 1g of graphene oxide in 1000mL of deionized water and ultrasonically disperse to obtain a graphene oxide dispersion; dissolve 1g of nickel chloride hexahydrate soluble metal salt in the above dispersion, fully stir for 1h and then let it stand Graphene oxide-nickel chloride mixed solution, remove the precipitate and wash once, put it in a vacuum oven for drying at 45°C, and then grind it into powder to obtain graphene oxide powder doped with metal nickel ions;

[0038] (2) Ultrasonic dispersion of the graphene oxide powder doped with nickel ions prepared in the step (1) in 100mL deionized water, then adding 2g of molybdenum-containing sodium molybdate solution, and stirring the mixed solution for 1h, After ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com