UV viscosity reducing composition, UV viscosity reducing film and preparation method thereof

A composition and film technology, applied in non-polymer organic compound adhesives, conductive adhesives, film/sheet adhesives, etc., can solve the problem that the performance is not completely stable, the residual glue is not easy to remove, and it is easy to adsorb. Dust and other problems, to achieve excellent anti-static effect, high production efficiency, easy to peel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

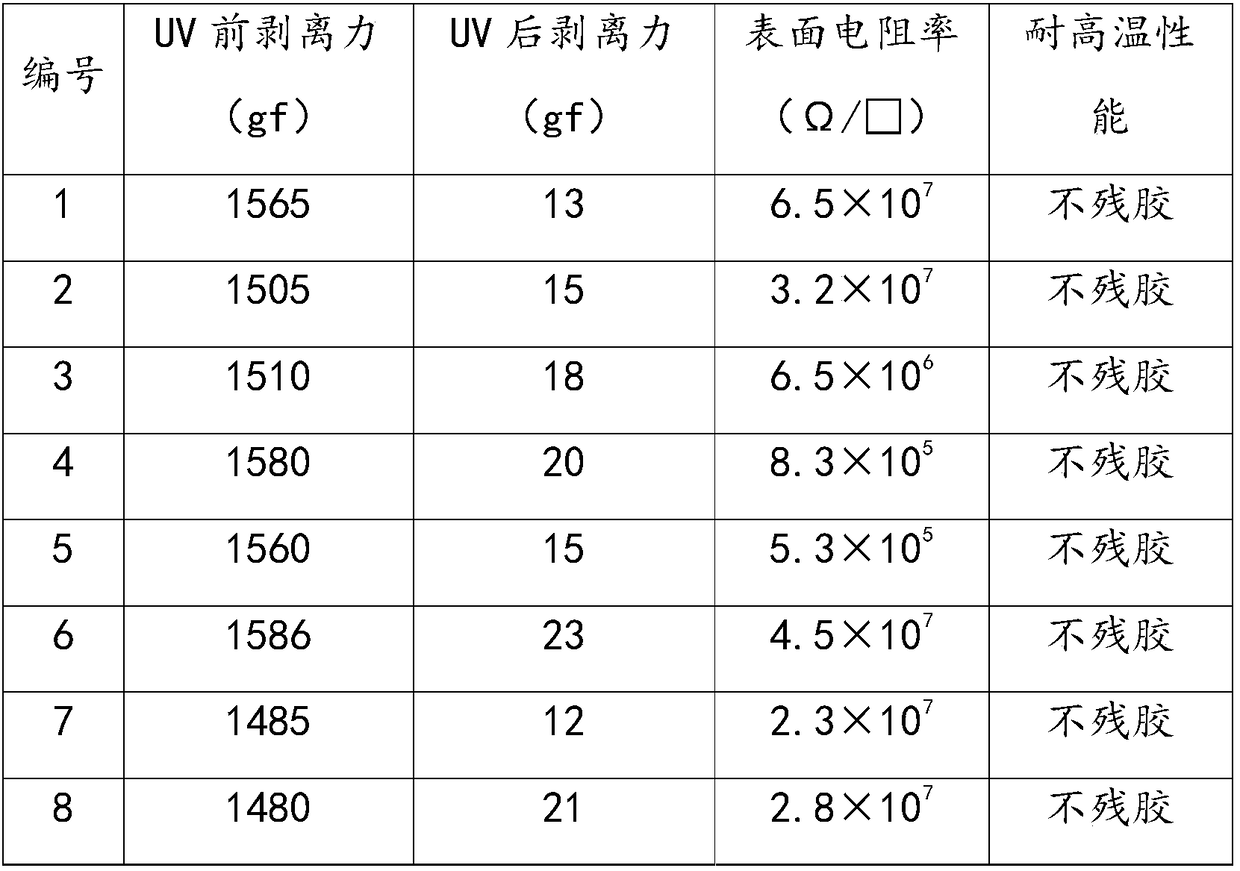

Embodiment 1

[0070] The UV viscosity-reducing composition described in the present embodiment, the raw material composition is as follows:

[0071] 40g high temperature resistant acrylic pressure-sensitive adhesive resin (manufacturer: Changxing Chemical Industry (China) Co., Ltd., model: ETERAC7710), 20g multifunctional oligomer (manufacturer: Huayao Chemical (Wuxi) Co., Ltd., model: UX- 5805W), 1g crosslinking agent (manufacturer: Bayer, Germany, model: N3390), 3g antistatic agent (manufacturer: Shenzhen Huigao Gold Standard Technology Co., Ltd., model: GW-2008), 0.8g dispersant (manufacturer : German BYK company, model: BYK-170), 0.2g leveling agent (manufacturer: German BYK company, model: BYK-333), 5g of 2,4,6-(trimethylbenzoyl) - Diphenylphosphine oxide (TPO), 30 g of butanone.

[0072] Wherein, the UX-5805W is an aliphatic urethane acrylate oligomer.

Embodiment 2

[0074] The UV viscosity-reducing composition described in the present embodiment, the raw material composition is as follows:

[0075] 40g high temperature resistant acrylic pressure-sensitive adhesive resin (manufacturer: Changxing Chemical Industry (China) Co., Ltd., model: ETERAC7710), 20g multifunctional oligomer (manufacturer: Huayao Chemical (Wuxi) Co., Ltd., model: UX- 5805W), 1g crosslinking agent (manufacturer: Bayer, Germany, model: N3390), 2g nano-graphite powder (manufacturer: Shanghai Youmo Composite Materials Co., Ltd.), 0.8g dispersant (manufacturer: BYK, Germany, Model: BYK-164), 0.2g leveling agent (manufacturer: BYK, Germany, model: BYK-306), 5g of 2,4,6-(trimethylbenzoyl)-diphenylphosphine oxide (TPO), 31 g of butanone.

[0076] Wherein, the particle size range of the nano-graphite powder is 50-100nm.

Embodiment 3

[0078] The UV viscosity-reducing composition described in the present embodiment, the raw material composition is as follows:

[0079] 40g high temperature resistant acrylic pressure-sensitive adhesive resin (manufacturer: Changxing Chemical Industry (China) Co., Ltd., model: ETERAC7710), 20g multifunctional oligomer (manufacturer: Huayao Chemical (Wuxi) Co., Ltd., model: UX- 5805W), 1g crosslinking agent (manufacturer: Bayer, Germany, model: N3390), 0.2g nano-graphene (manufacturer: Hefei Microcrystalline Material Technology Co., Ltd.), 0.8g dispersant (manufacturer: BYK, Germany , model: BYK-180), 0.2g leveling agent (manufacturer: BYK, Germany, model: BYK-390), 5g of 2,4,6-(trimethylbenzoyl)-diphenyl oxide Phosphine (TPO), 32.8 g of butanone.

[0080] Wherein, the particle size range of the nano-graphene is 5-20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com