Mulberry blueberry wine and production process thereof

A production process, blueberry wine technology, applied in the direction of microorganisms, preparation of alcoholic beverages, methods based on microorganisms, etc., can solve the problems of easy precipitation, single ingredients, poor taste, etc., and achieve improved fruit wine flavor, unique style, and complete fermentation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

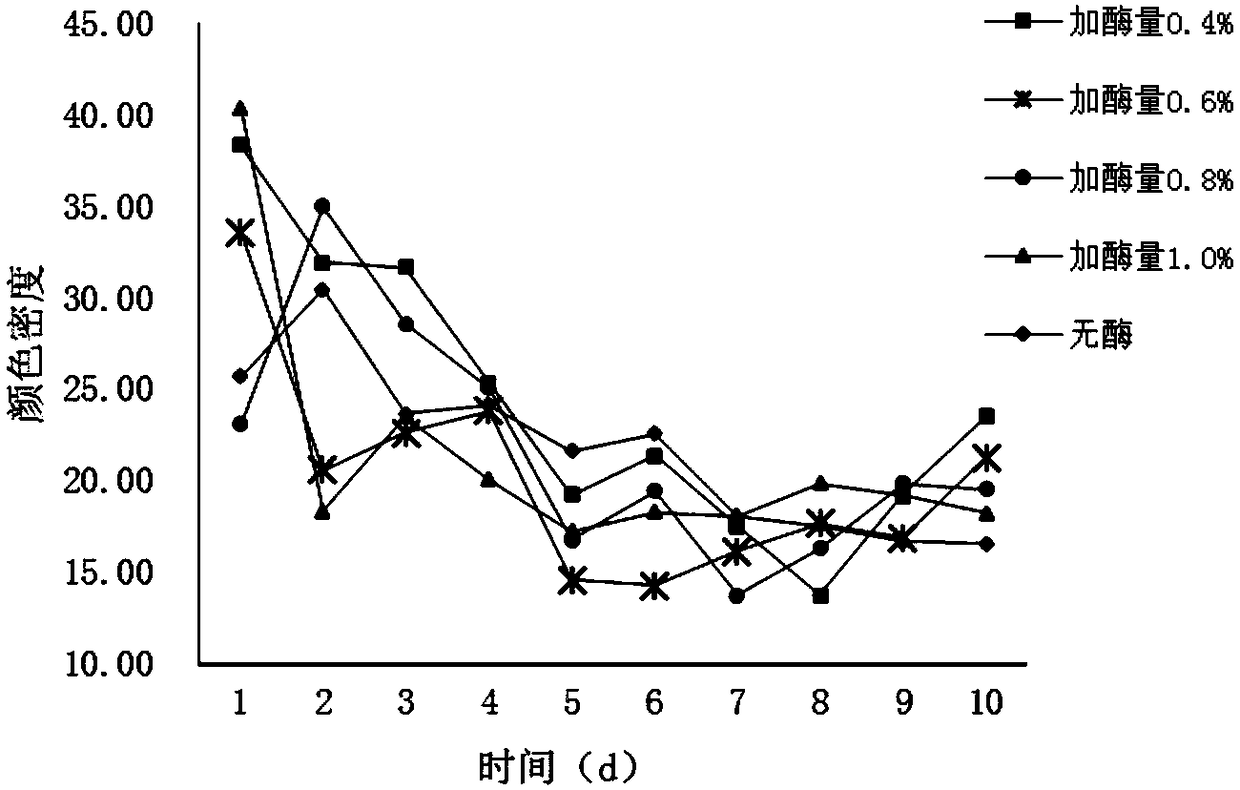

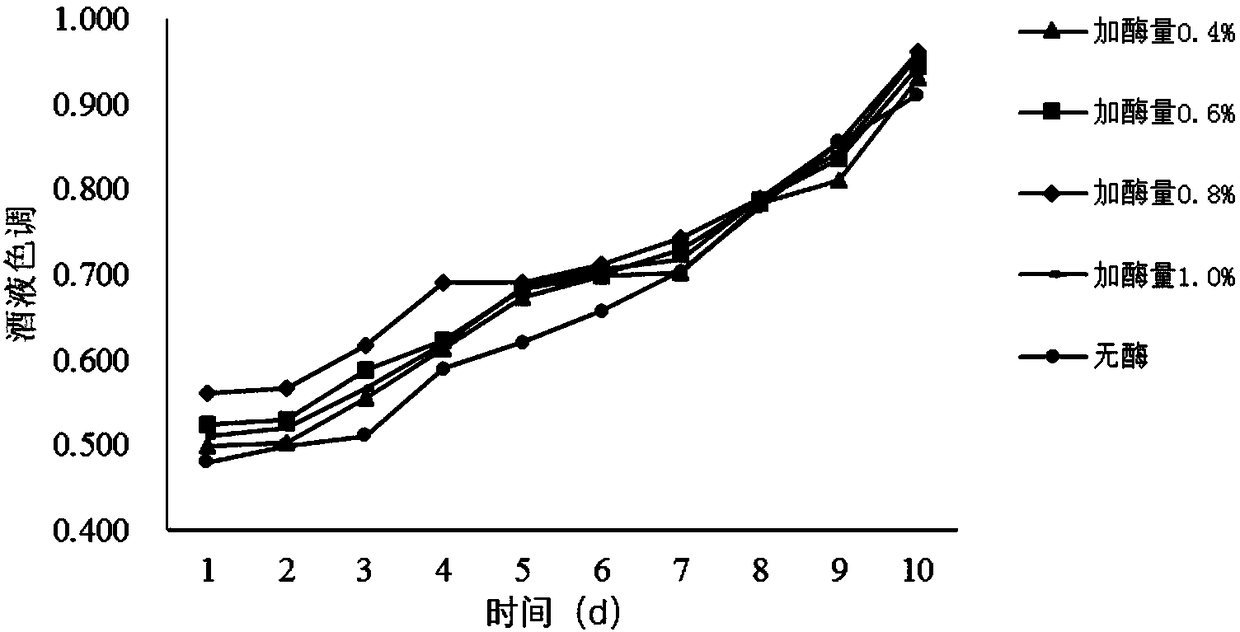

[0040] Select 10kg of fresh ripe mulberries and 2kg of fresh ripe blueberries, wash, destem, and crush, beat for 5 minutes with a beater, add 9.6g of potassium metabisulfite (0.08% of the total weight of mulberries and blueberries), and stir evenly; Glue compound enzyme and cellulase are mixed according to the mass ratio of 1:1, and the total enzyme accounts for 0%, 0.4%, 0.6%, 0.8% and 1.0% of the total mass of mulberry and blueberry respectively, and is added to the mulberry and blueberry slurry at a temperature of 22 Enzymolysis at ℃ for 8 hours to prepare mulberry and blueberry juice;

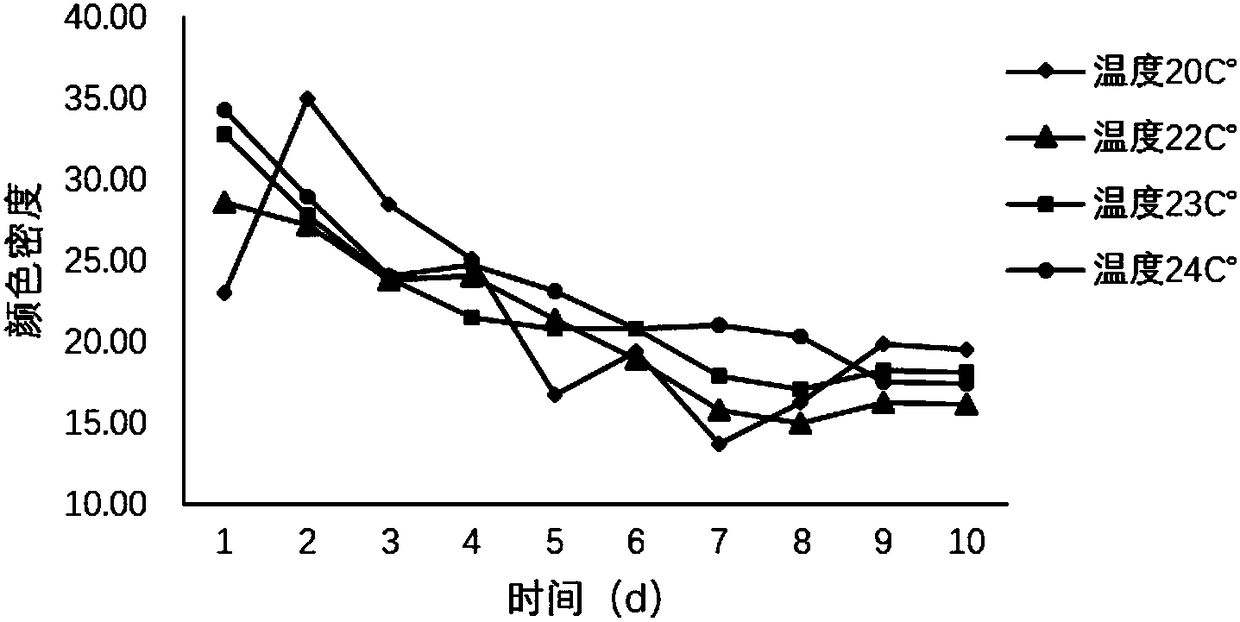

[0041] Pump the mulberry and blueberry juice into the fermenter with a slurry pump, add 22% white granulated sugar of the mulberry and blueberry juice quality, stir evenly, then add activated Saccharomyces cerevisiae (the addition is 0.5% of the mulberry and blueberry juice quality), and place in Sealed fermentation was carried out at 20°C, 22°C, 23°C and 24°C, and samples were taken every ...

Embodiment 2

[0043] Take the production of 10 tons of mulberry and blueberry wine as an example.

[0044] Select 10 tons of fresh ripe mulberries and 2 tons of fresh ripe blueberries, wash, destem, and crush, beat with a beater for 5 minutes, add 9.6kg of potassium metabisulfite (0.08% of the total weight of mulberries and blueberries), and stir evenly; Mix pectin compound enzyme and cellulase at a mass ratio of 1:1 to obtain 96 kg of total enzyme (0.8% of the total mass of mulberry and blueberry), add it to the mulberry and blueberry slurry, and enzymolyze it at a temperature of 22°C for 8 hours to obtain Mulberry blueberry juice;

[0045] The mulberry and blueberry juice is pumped into the fermenter with a slurry pump, add 2.6 tons of white granulated sugar (22% of the mulberry and blueberry juice quality), stir evenly, then add activated Saccharomyces cerevisiae (the addition is 0.5% of the mulberry and blueberry juice quality) ), placed at a temperature of 22°C for sealed fermentation...

Embodiment 3

[0050] Take the production of 5 tons of mulberry and blueberry wine as an example.

[0051] Choose 3 tons of fresh ripe mulberries and 3 tons of fresh ripe blueberries, wash, destem, crush, beat with a beater for 3 minutes, add 3.6kg of potassium metabisulfite (0.06% of the total weight of mulberries and blueberries), and stir evenly Add 7.2kg of pectin compound enzyme (0.12% of the total mass of mulberry and blueberry), and enzymolyze it for 20h at 15°C to obtain mulberry juice;

[0052] The mulberry blueberry juice is pumped into the fermenter with a slurry pump, adds 0.6 tons of white granulated sugar (10% of the mulberry blueberry juice quality), stirs evenly, and then adds activated Saccharomyces cerevisiae (the addition is 0.05% of the mulberry blueberry juice quality). ), placed at a temperature of 15°C for sealed fermentation, and when the total sugar content in the fermentation broth is determined to be below 3.0g / L and the alcohol content is 10-14% Vol, the fermentat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com