Composition for removing resist

A composition and resist technology, applied in the directions of detergent compositions, surface active detergent compositions, non-surface active detergent compositions, etc., can solve the problems of slow evaporation speed, interface outflow, slow rotation speed, etc. High solvency, improved productivity, and effect of preventing re-adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

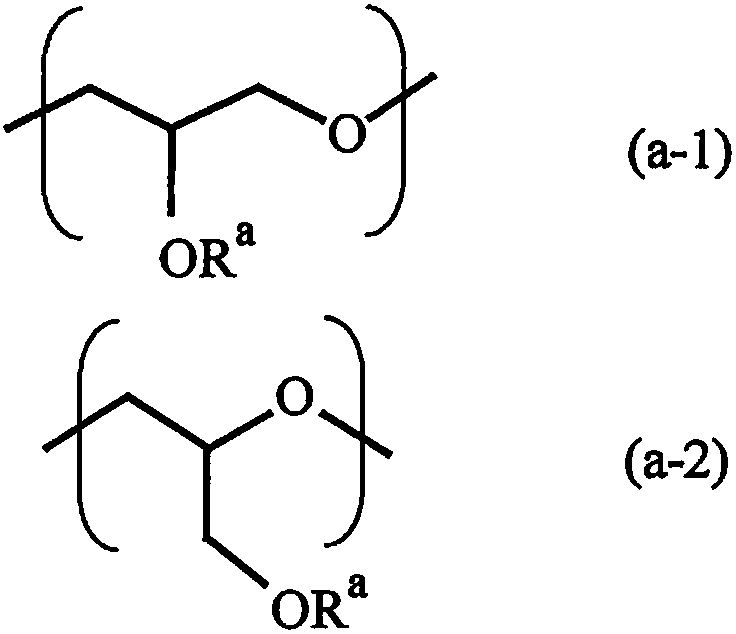

[0169] Preparation example 1 (preparation of polyglycerol derivative (A-1))

[0170] 90 parts by weight of glycerin and 1 part by weight of a 48% by weight NaOH aqueous solution as an alkali catalyst were put into the reaction vessel, and 2-ethylhexylglycidol was added dropwise thereto over 12 hours while maintaining the temperature in the reaction vessel at 100°C. 3540 parts by weight of ether (the amount of 19 mol relative to 1 mol of glycerin) was then aged for 1 hour. Thereafter, 85% by weight of phosphoric acid aqueous solution was added to terminate the reaction to obtain a polyglycerol derivative (A-1).

preparation example 2

[0171] Preparation example 2 (preparation of polyglycerol derivative (A-2))

[0172] In place of glycerin, decaglycerol was used, and the amount of 2-ethylhexyl glycidyl ether used was changed to 10 mol per 1 mol of decaglycerol. In the same manner as in Preparation Example 1, polyglycerol derivatives were obtained. Object (A-2).

preparation example 3

[0173] Preparation example 3 (preparation of polyglycerol derivative (A-3))

[0174] 1500 parts by weight of poly(20) glycerol, 2000 parts by weight of lauric acid (10 mol relative to 1 mol of poly(20) glycerol) and 1 part by weight of 48% by weight sodium hydroxide aqueous solution were put into the reaction vessel, and the , the temperature in the reaction vessel was raised to 200° C. under normal pressure, and the reaction was carried out for 10 hours. After completion of the reaction, the temperature in the reaction container was cooled to normal temperature to obtain a polyglycerol derivative (A-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com