Chinese medicinal plaster for treatment of gout and preparation method thereof

A technology of plaster and traditional Chinese medicine, which is applied in the field of medicine for treating gout and traditional Chinese medicine plaster for treating gout. It can solve the problems of side effects of medicine, high asymptomatic index, and difficulty in radical cure, etc., and achieve the effects of no toxic side effects, quick effect, and not easy to relapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

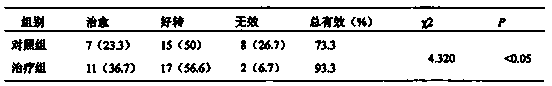

Examples

Embodiment 1

[0021] (1) Weighing: Weigh the following components according to the ratio: 60 parts of Jialan, 60 parts of Smilax, 50 parts of Clematis, 50 parts of A. 30 parts of Shanzi mushroom, 30 parts of Touguxiang, 30 parts of camphor root, 20 parts of coix seed, 20 parts of plantain seed.

[0022] (2) Cleaning: Soak each component in clean water for 10 minutes, and then clean the floating ash on the surface of each component.

[0023] (3) Pulverization: each component is sun-dried or dried after being selected to remove impurities, and placed in the pulverization equipment (Ruian Baixin Pharmaceutical Machinery Co., Ltd. ultrafine pulverizer LG-01) according to the stated weight. 2 times for 5 minutes, pulverize into fine powder and pass through a 300-mesh sieve, freeze the obtained powder at -20°C for 12 hours, and put it into a high-speed continuous ultrafine pulverizer (XLF-30B, Guangzhou Xulang Machinery Equipment Co., Ltd.) for pulverization. Take out 600 mesh sieves, the measur...

Embodiment 2

[0029] (1) Weighing: Weigh each component according to the ratio: 50 parts of Jialan, 50 parts of Smilax smilax, 40 parts of Clematis, 40 parts of scorpion, 40 parts of Jiujiefeng, 40 parts of Yinyang lotus, 25 parts of clover 25 parts of Shanzi mushroom, 25 parts of Touguxiang, 25 parts of camphor root, 15 parts of coix seed, 15 parts of plantain seed.

[0030] (2) Cleaning: Soak each component in clean water for 5 minutes, and then clean the floating ash on the surface of each component.

[0031] (3) Pulverization: each component is sun-dried or dried after being selected to remove impurities, and placed in the pulverization equipment (Ruian Baixin Pharmaceutical Machinery Co., Ltd. ultrafine pulverizer LG-01) according to the stated weight. 2 times for 5 minutes, pulverize into fine powder and pass through a 300-mesh sieve, freeze the obtained powder at -20°C for 12 hours, and put it into a high-speed continuous ultrafine pulverizer (XLF-30B, Guangzhou Xulang Machinery Equi...

Embodiment 3

[0037] (1) Weighing: Weigh each component according to the ratio: 40 parts of Jialan, 40 parts of Smilax smilax, 30 parts of Clematis, 30 parts of scorpion, 30 parts of Jiujiefeng, 30 parts of Yinyang lotus, 20 parts of clover 20 parts of Shanzi mushroom, 20 parts of Touguxiang, 20 parts of camphor root, 10 parts of coix seed, 10 parts of plantain seed.

[0038] (2) Cleaning: Soak each component in clean water for 7 minutes, and then clean the floating ash on the surface of each component.

[0039] (3) Pulverization: each component is sun-dried or dried after being selected to remove impurities, and placed in the pulverization equipment (Ruian Baixin Pharmaceutical Machinery Co., Ltd. ultrafine pulverizer LG-01) according to the stated weight. 2 times for 5 minutes, pulverize into fine powder and pass through a 300-mesh sieve, freeze the obtained powder at -20°C for 12 hours, and put it into a high-speed continuous ultrafine pulverizer (XLF-30B, Guangzhou Xulang Machinery Equi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com