Membrane production and gas purification integrated device, membrane production and gas purification method

A gas purification and air technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of low mineralization efficiency, easy deactivation, and difficulty in fixing nano-catalysts, so as to increase the effective area and contact time, preventing pollution deactivation, and improving the efficiency of photocatalytic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

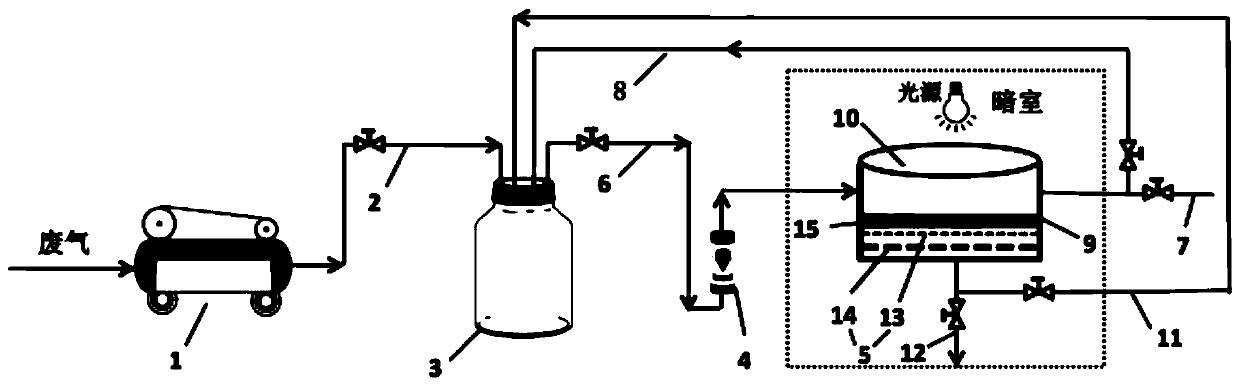

[0038] A membrane forming and gas purification integrated device of the present invention, such as figure 2 As shown, the integrated device for film making and gas purification includes an air compressor 1, a mixing buffer bottle 3 and a film making container 9 connected in sequence. on the support layer 5 of the support membrane.

[0039] In this embodiment, the mixing buffer bottle 3 is provided with a first inlet and a first outlet, the side of the film-making container 9 is provided with an air inlet and a feed return port, and the bottom is provided with an air outlet, which can be used during the film-making process. It can be connected to a vacuum pump for vacuum suction filtration, and can be used to connect a gas chromatographic detector to determine the concentration of VOCs during the gas purification process. The first inlet of the mixing buffer bottle 3 communicates with the air compressor 1 through the first pipeline 2, and the first outlet of the mixing buffer...

Embodiment 2

[0046] A membrane forming and gas purification method of the present invention comprises the following steps:

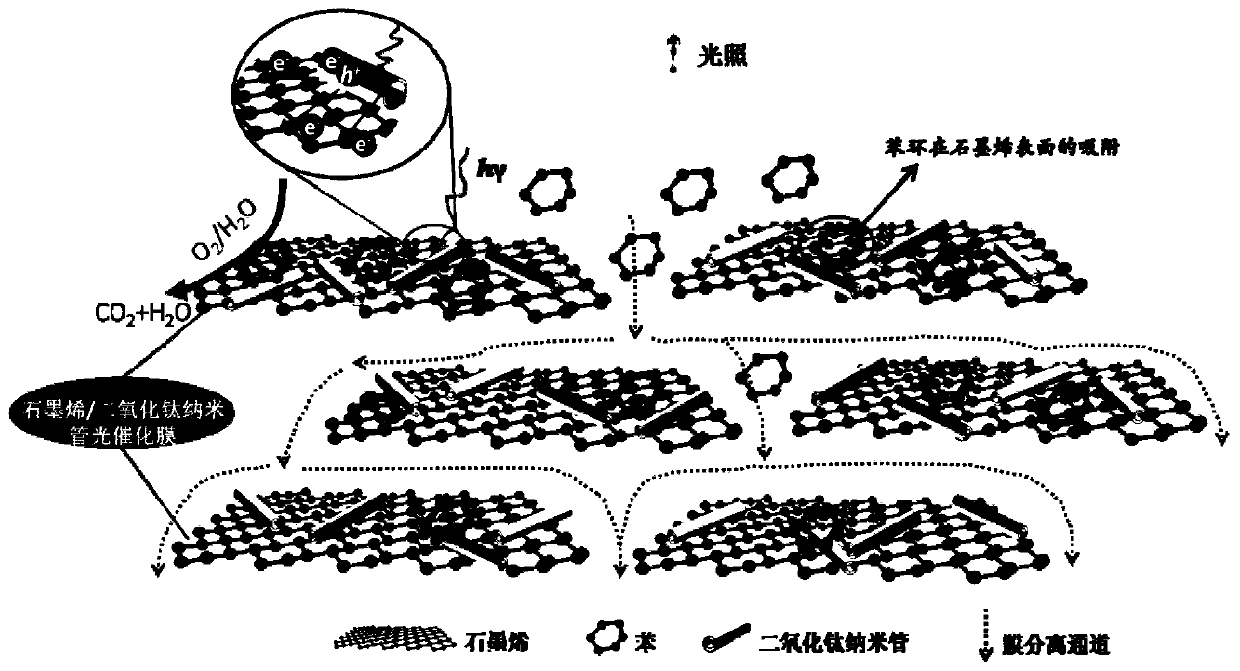

[0047] (S1) Membrane-making: adopt the membrane-making and gas purification integrated device of above-mentioned embodiment 1, first open feed pipe 7, close other pipelines, add the suspension (film-casting solution) containing graphene oxide and nano-photocatalyst In the film-making container 9, the air outlet of the film-making container 9 is connected to a circulating water vacuum pump, and the vacuum filtration method is used for suction filtration to obtain a graphene oxide-based photocatalytic film, and the graphene oxide-based photocatalytic film is processed by ultraviolet light After irradiating for 3 hours, during this process, the photogenerated electrons generated by the nano-photocatalyst reduce the graphene oxide to graphene, and a graphene-based photocatalytic film 15 is obtained.

[0048] (S2) Gas purification: open the first pipeline 2, the second pi...

Embodiment 3

[0055] Using the device of Example 1 and the method of Example 2, the only difference is that titanium dioxide nanotubes are replaced by titanium dioxide nanoparticles. When the ratio of raw materials is that the mass ratio of graphene oxide to nano photocatalyst is 1:0, 1:0.25, 1:0.5, 1:1, 1:2, 1:3, 1:4, 1:5, the nano When the particle size is from 20nm to 100nm, after XRD characterization and calculated by the Bragg formula, the interlayer spacing of the photocatalytic film can be increased from 0.896nm of the original graphene oxide to 1.532nm of the graphene embedded with nanoparticles, and the gas film permeation flux is 2ml / min increased to 580ml / min, the removal rate of toluene was 17%-98%, and the embedding of nanoparticles ensured a higher flux of air permeation during the separation process of the photocatalytic membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com