Narrow distribution gemini surfactant and preparation method thereof

A technology of gemini surface and active agent, applied in the field of narrow distribution gemini surfactant and its preparation, can solve the problems of poor product performance synthesis method, unable to guarantee the stability of alkynyl group, wide product molecular weight distribution, etc., and achieve the alkynyl group retention rate Low, improve the narrow distribution characteristics, the effect of strong alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

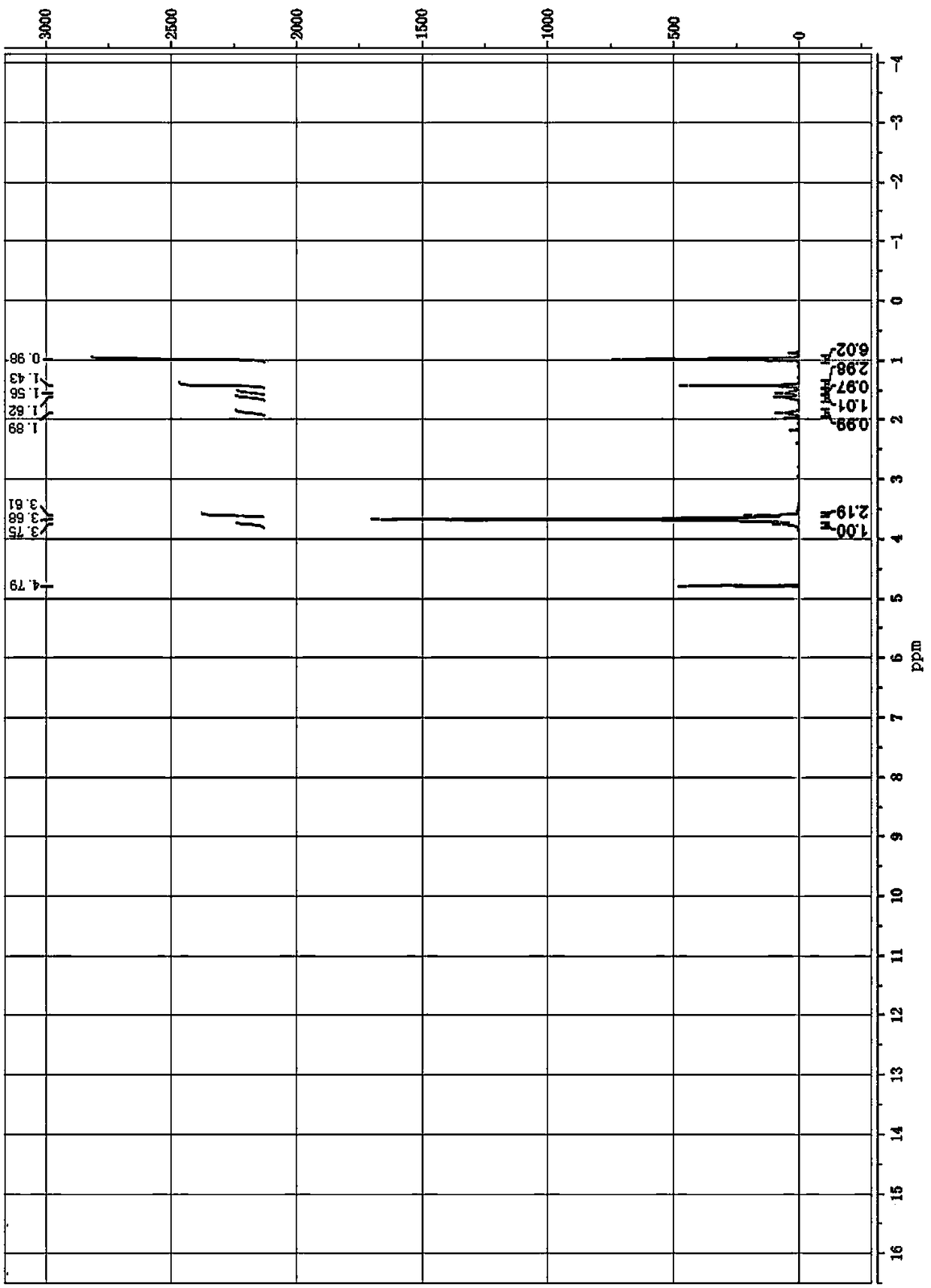

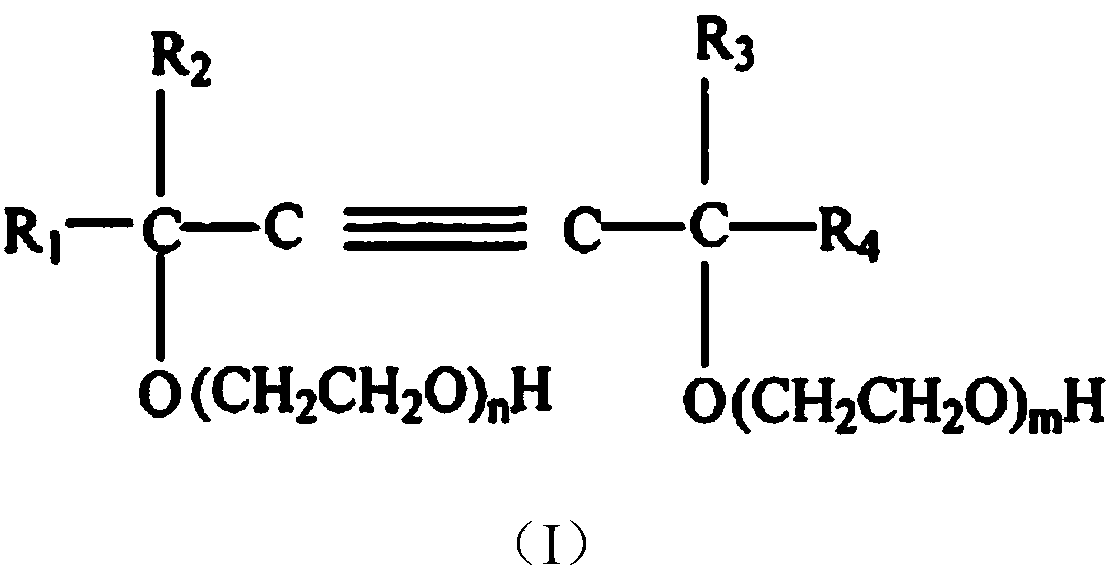

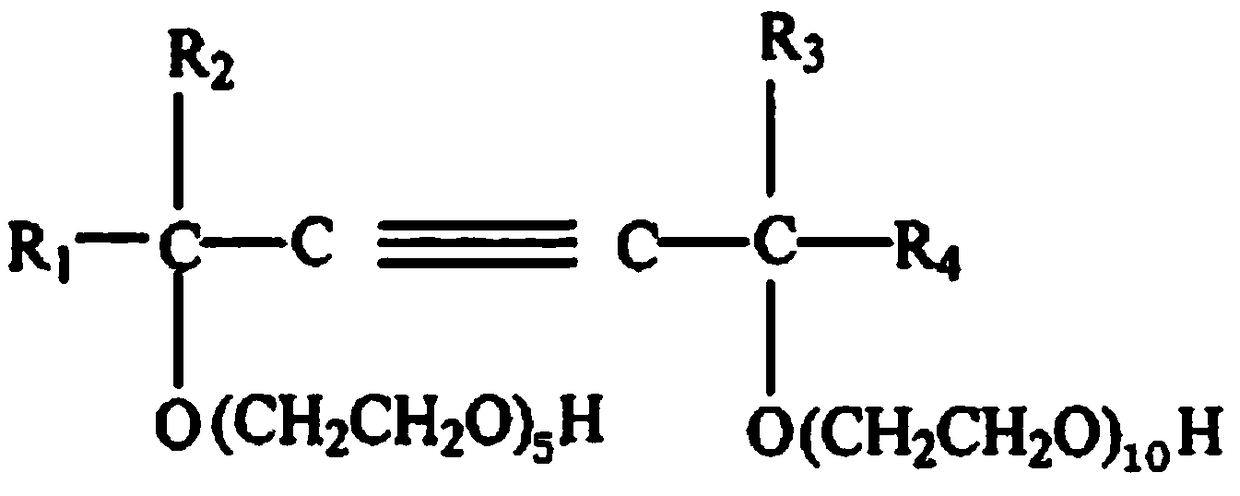

[0029] Add 1 mol of acetylenic diol and 5 g of 1,8-diazabicycloundec-7-ene (DBU) into a 1 L stirred autoclave, check the airtightness of the reactor, and wait for 1 hour After there is no pressure drop in the interior, carry out nitrogen replacement and vacuuming operations at 50°C to ensure that the vacuuming time is greater than 30 minutes, and the number of high-purity nitrogen replacement operations is 5 times. Feed ethylene oxide, control the reaction temperature to be 120°C±3°C and the reaction pressure to be 0.3MPa~0.5MPa, stop feeding ethylene oxide until the total amount of ethylene oxide passed is 10mol, and carry out the product Post-treatment Aging Maintain the temperature of the reactor at 120°C±3°C until the pressure of the reactor no longer drops, indicating that the aging reaction is completed. Lower the temperature to 60°C, neutralize with glacial acetic acid and remove the low boiling point to obtain a narrow distribution gemini surfactant.

[0030] The stru...

Embodiment 2

[0032] Add 1 mol of acetylenic diol and 5 g of 1,8-diazabicycloundec-7-ene (DBU) in a 1 L stirred autoclave, and check the airtightness of the reactor. After there is no pressure drop within 1 hour, carry out nitrogen replacement and vacuuming operations at 50°C to ensure that the vacuuming time is greater than 30 minutes, and the number of high-purity nitrogen replacement operations is 5 times. Feed ethylene oxide into the kettle, control the reaction temperature to be 90°C±3°C and the reaction pressure to be 0.3MPa~0.5MPa, stop feeding ethylene oxide until the total amount of ethylene oxide is 10mol. After the product is processed and aged, the temperature of the reactor is maintained at 90°C ± 3°C until the pressure of the reactor no longer drops, indicating that the aging reaction is completed. Lower the temperature to 60°C, neutralize with glacial acetic acid and remove the low boiling point to obtain a narrow distribution gemini surfactant.

Embodiment 3

[0034] Add 1 mol of acetylene diol and 2.5 g of 1,4-diazabicyclo[2.2.2]octane (ABCO) and 2.5 g of 1,4-diazobicyclo[ 2.2.2] Octane (DABCO) was used as a catalyst to check the airtightness of the reactor. After the reactor did not experience pressure drop within 1 hour, it was replaced with nitrogen and vacuumed at 50°C to ensure that the reactor was vacuumed. The vacuum time is greater than 30min, the number of high-purity nitrogen replacement operations is 5 times, the pressure is exhausted to 0-30KPa, and then ethylene oxide is introduced into the reactor, and the reaction temperature is controlled at 00°C±3°C and the reaction pressure is 0.3MPa-0.5 MPa, stop feeding ethylene oxide until the total amount of ethylene oxide fed is 10mol, and carry out post-treatment aging on the product to maintain the temperature of the reactor at 90°C±3°C until the pressure of the reactor no longer drops, indicating completion ripening reaction. Lower to 60°C, neutralize with glacial acetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com