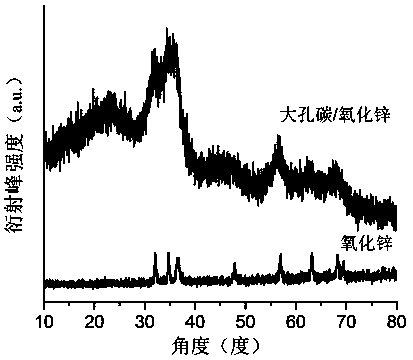

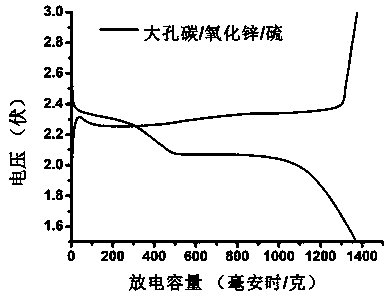

Macroporous carbon/oxide zinc/sulfur composite material for lithium-sulfur battery as well as preparation method and application of macroporous carbon/oxide zinc/sulfur composite material

A composite material, lithium-sulfur battery technology, applied in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc., can solve the problem of active sulfur loss, achieve strong adsorption, improve rate performance and cycle performance, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1) Preparation of monodisperse silica microspheres:

[0048] The n-disilicate ethyl silicate and absolute ethanol solution were mixed together according to the volume ratio of 1:15. In addition, mix concentrated ammonia water, absolute ethanol, and deionized water together at a volume ratio of 1:3:15. The two groups of solutions were mixed together, stirred with a magnetic stirrer for 12 hours, then centrifuged, and dried in a vacuum oven for 12 hours to obtain silica microspheres with a diameter of 200-300 nm.

[0049] 2) Preparation of silica template:

[0050] Take an appropriate amount of the above-mentioned silica microspheres and grind them into powder, make a 10wt% solution with ethanol solution, put it in a beaker, and ultrasonicate it, so that the silica microspheres are evenly dispersed in the ethanol solution, and then make it at 40°C After standing still, after volatilization and drying, neatly arranged SiO 2 template.

[0051] 3) Preparation of 3D order...

Embodiment 2

[0058] This embodiment is the second embodiment of preparing macroporous carbon / zinc oxide / sulfur composite material, and the difference from embodiment 1 is that in the step of preparing silica microspheres, ethyl n-disilicate and no The water-ethanol solution is mixed together according to the volume ratio of 1:25, and the concentrated ammonia water, absolute ethanol and deionized water are mixed together according to the volume ratio of 1:3:15.

[0059] Other preparation methods and parameters are the same as in Example 1.

Embodiment 3

[0061] This embodiment is the 3rd embodiment that prepares the macroporous carbon / zinc oxide / sulfur composite material, and the difference with embodiment 1 is, in the step of preparing silicon dioxide microspheres, ethyl n-disilicate and no The water-ethanol solution is mixed together according to the volume ratio of 1:15, and the concentrated ammonia water, absolute ethanol and deionized water are mixed together according to the volume ratio of 1:5:20.

[0062] Other preparation methods and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com