Electronic material and preparation method thereof

An electronic material, mesoporous silica technology, applied in the direction of electronic equipment, chemical instruments and methods, other household appliances, etc., to achieve the effect of good adhesion, excellent heat resistance and flame retardancy, and avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

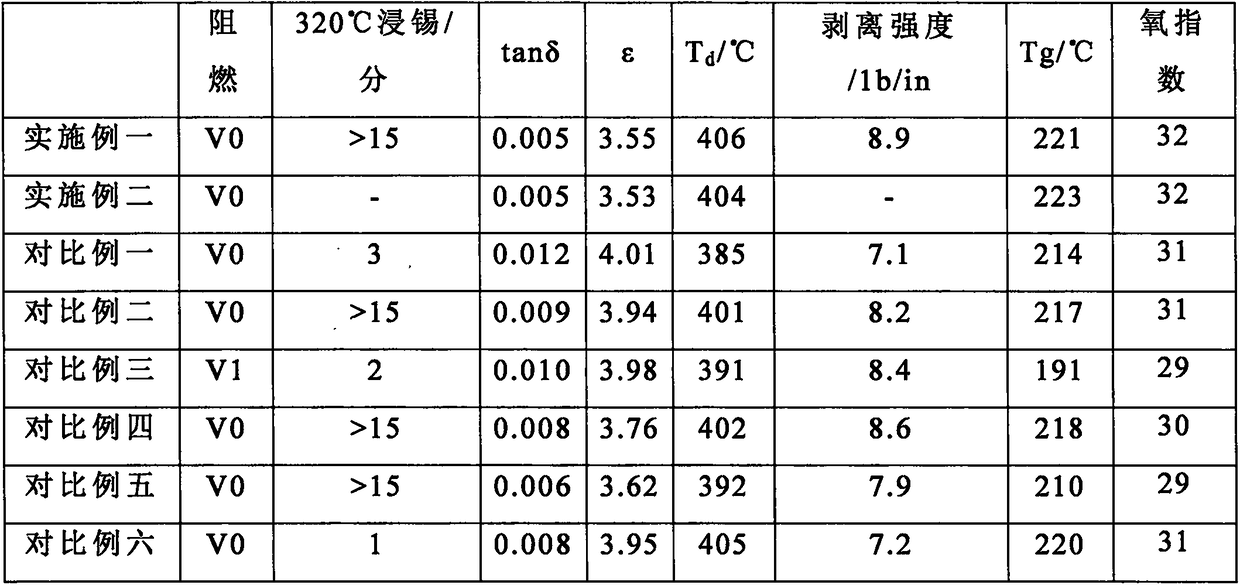

Examples

Embodiment 1

[0039] Embodiment 1 An electronic material, its preparation method comprises the following steps:

[0040] (1) Add mesoporous silica to concentrated sulfuric acid, filter to obtain a filter cake after ultrasonic treatment for 10 minutes, then wash and dry the filter cake to obtain acid-etched mesoporous silica; combine acid-etched mesoporous silica with normal After mixing ethyl silicate, stir at 150°C for 1 hour, then add 3,3'-dithiodipropionic acid and butyl acrylate, and stir at 70°C for 40 minutes to obtain a modified silica system;

[0041] (2) At room temperature, mix 3,3'-dithiodipropionic acid, dichloromethane, and acetone; then add pyridinium m-nitrobenzenesulfonate and manganese acetate, stir for 30 minutes, and then add N-methylolpropene Amide, after stirring for 3 hours, add 2,3-epoxy cyclopentyl cyclopentyl ether, after stirring for 50 minutes, add methylcyclohexene tetracarboxylic dianhydride, continue stirring for 20 minutes; then add N, N' -dicyclohexylcarbodi...

Embodiment 2

[0047] Embodiment 2 An insulating board for electronic materials, the preparation method of which comprises the following steps:

[0048] (1) Add mesoporous silica to concentrated sulfuric acid, filter to obtain a filter cake after ultrasonic treatment for 10 minutes, then wash and dry the filter cake to obtain acid-etched mesoporous silica; combine acid-etched mesoporous silica with normal After mixing ethyl silicate, stir at 150°C for 1 hour, then add 3,3'-dithiodipropionic acid and butyl acrylate, and stir at 70°C for 40 minutes to obtain a modified silica system;

[0049] (2) At room temperature, mix 3,3'-dithiodipropionic acid, dichloromethane, and acetone; then add pyridinium m-nitrobenzenesulfonate and manganese acetate, stir for 30 minutes, and then add N-methylolpropene Amide, after stirring for 3 hours, add 2,3-epoxy cyclopentyl cyclopentyl ether, after stirring for 50 minutes, add methylcyclohexene tetracarboxylic dianhydride, continue stirring for 20 minutes; then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com