Acetenyl polyimide modified cyanate ester adhesive and preparation method thereof

An acetylene-based polyimide, acetylene-based polyimide resin technology, applied in the directions of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of poor thermal stability and insufficient toughness, and achieve improved Effects of heat resistance and bond strength, good modulus retention, high crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific Embodiment 1: The ethynyl polyimide modified cyanate adhesive in this embodiment includes 100 parts by weight of cyanate resin, 1-100 parts of ethynyl polyimide resin and 1-10 parts of inorganic filler Modifier; wherein the cyanate resin is one or several of bisphenol A cyanate, dicyclopentadiene bisphenol cyanate, bisphenol F cyanate, novolac cyanate A mixture composed in any ratio; the inorganic filler modifier is one of hollow ceramic microspheres, fumed silicon dioxide, bentonite, and nano-silicon carbide, or a mixture of several of them composed in an arbitrary ratio.

specific Embodiment approach 2

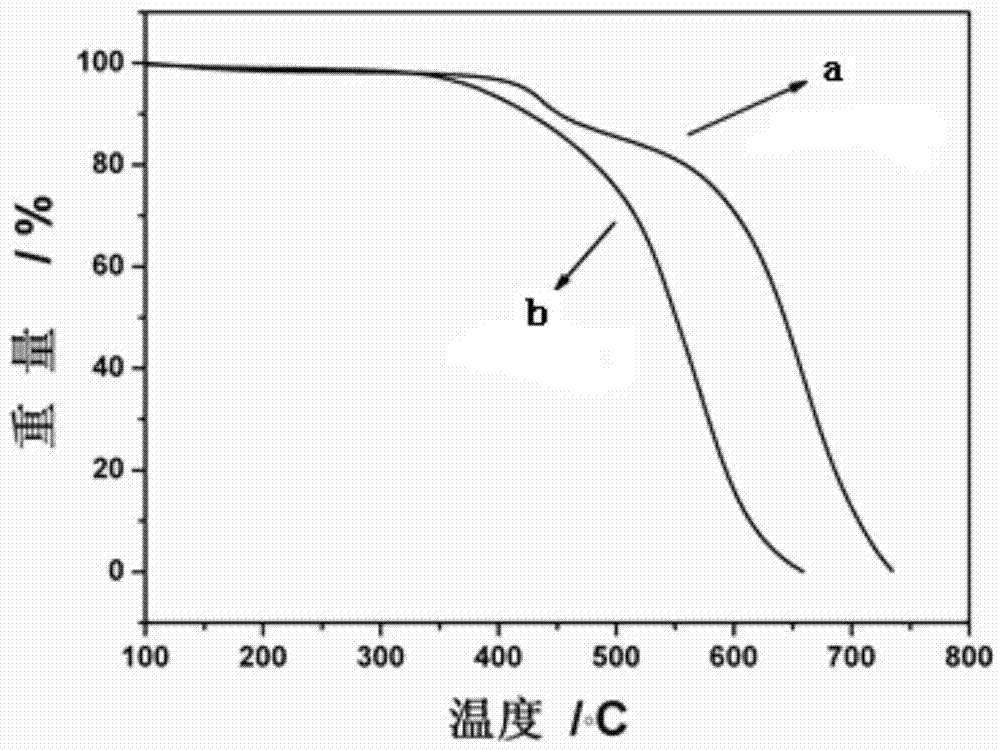

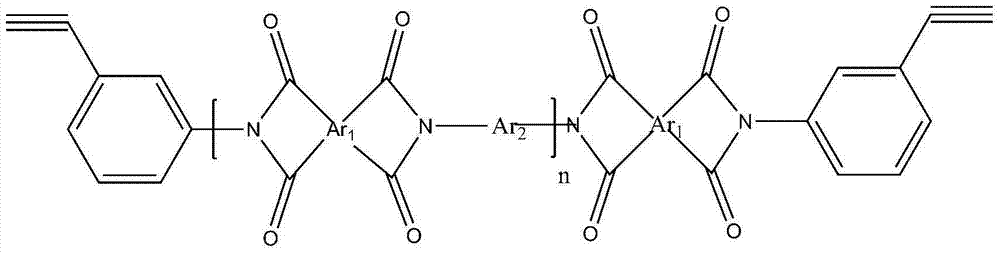

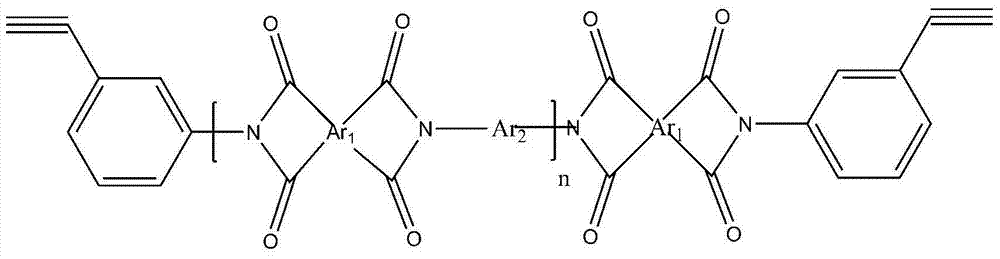

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the structural formula of the ethynyl polyimide resin is:

[0033]

[0034] , where the degree of polymerization n is 1-9, Ar 1 for Ar 2 for Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035]Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the ethynyl polyimide resin is prepared according to the following steps: add N,N-dimethyl Acetamide, under a nitrogen atmosphere, add aromatic dianhydride to N,N-dimethylacetamide, add aromatic diamine after stirring for 1 hour, and stir for 1 to 5 hours to obtain a mixed solution; add dimethicone to the mixed solution Ethynylaniline, stirred and reacted for 1-5 hours, wherein the molar ratio of aromatic dianhydride, aromatic diamine and m-ethynylaniline is 1:0.5-0.9:0.2-1; then add toluene, heat up to 120-130°C for reflux reaction 1 to 4 hours; after the solution has dropped to room temperature, add it dropwise into absolute ethanol, precipitate for 1 hour and then filter, wash the precipitate with 80°C absolute ethanol for 3 times, and dry at 130°C to 140°C to obtain ethynyl Polyimide resin; wherein the mass ratio of N,N-dimethylacetamide and toluene is 10:3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com