Method for preparing carbon material from flocculated sludge and petroleum coke and carbon material

A technology of petroleum coke and carbon materials, applied in the field of printing and dyeing wastewater treatment, can solve the problems of secondary pollution of the atmosphere, volume reduction, improper collection and control of leachate, etc., and achieve the effect of protecting the environment and protecting the economy and generating income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: The embodiment of the present invention discloses a method for preparing carbon materials by using flocculation sludge and petroleum coke, including the following steps:

[0041] Step d: The dye wastewater comes from a local printing and dyeing enterprise. Take 5L of dye wastewater. When flocculating, the dye concentration is 200ppm, and the pH of the solution is adjusted to 8.5; add cationic flocculant BADT-CTS (2,4-bis(dimethylammonium) -6-Chloro-[1,3,5]-triazine-based chitosan ether, the flocculant concentration is controlled at 9g / L, let it stand for a day, remove the upper liquid, and centrifuge the lower solid to accelerate solid-liquid separation. The rotational speed was 4500 rpm, and the centrifugation time was 15 minutes to obtain solid flocs.

[0042] Step a: Dry the solid flocs obtained in step d by blasting at 100°C for 45 hours, grind them into 120-mesh powder, and dry them in vacuum at 60°C for 6 hours to obtain dry flocculated sludge; take ...

Embodiment 2

[0046] Embodiment 2: The embodiment of the present invention discloses a carbon material prepared by using flocculation sludge and petroleum coke, and its preparation method includes the following steps:

[0047] Step d: The dye wastewater comes from a local printing and dyeing enterprise. Take 5L of dye wastewater. When flocculating, the dye concentration is 200ppm, and the pH of the solution is adjusted to 8.5; add cationic flocculant BADT-CTS (2,4-bis(dimethylammonium) -6-Chloro-[1,3,5]-triazine-based chitosan ether, the flocculant concentration is controlled at 9g / L, let it stand for a day, remove the upper liquid, and centrifuge the lower solid to accelerate solid-liquid separation. The rotational speed was 4500 rpm, and the centrifugation time was 15 minutes to obtain solid flocs.

[0048] Step a: Dry the solid flocs obtained in step d by blasting at 100°C for 45 hours, grind them into 120-mesh powder, and dry them in vacuum at 60°C for 6 hours to obtain dry flocculated ...

Embodiment 3

[0060] Embodiment 3: The embodiment of the present invention discloses a method for preparing carbon materials using flocculation sludge and petroleum coke, including the following steps:

[0061] Step d: The dye wastewater comes from a local printing and dyeing enterprise. Take 5L of dye wastewater. When flocculating, the dye concentration is 500ppm, and the pH of the solution is adjusted to 7.5; add cationic flocculant BADT-CTS (2,4-bis(dimethylammonium) -6-Chloro-[1,3,5]-triazine-based chitosan ether, the flocculant concentration is controlled at 12g / L, let it stand for a day, remove the upper liquid, and centrifuge the lower solid to accelerate solid-liquid separation, centrifuge The rotational speed was 4200 rpm, and the centrifugation time was 12 minutes to obtain solid flocs.

[0062] Step a: The solid flocs obtained in step d are air-dried at 105°C for 42 hours, ground into 110-mesh powder, and vacuum-dried at 75°C for 8 hours to obtain dry flocculated sludge; take 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

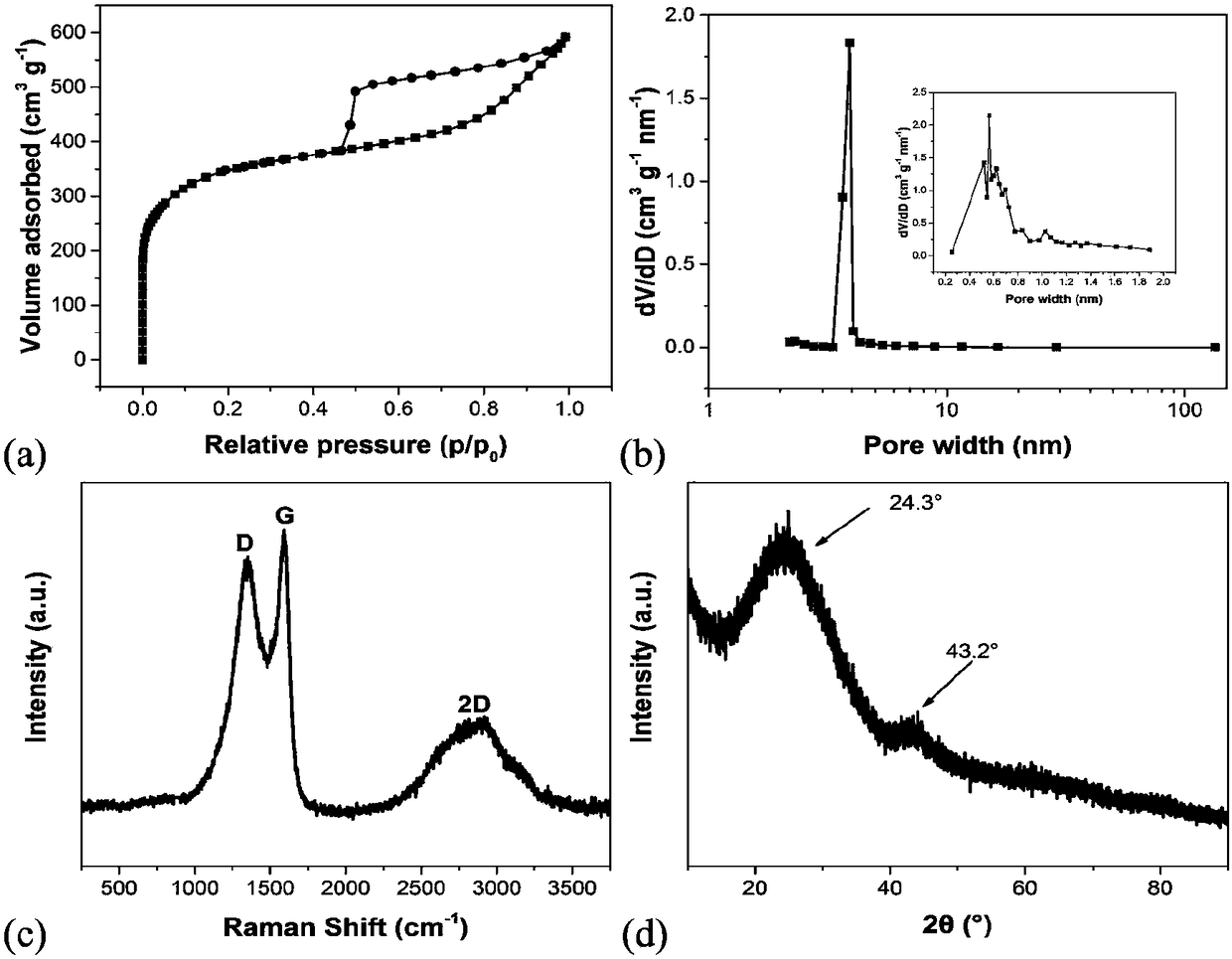

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com