Method for preparing SnO2/Ag2O composite particles through electrostatic spinning method

A technology of composite particles and synthesis methods, which is applied in the direction of chemical instruments and methods, silver compounds, silver compounds, etc., can solve problems such as obvious differences, strong adjustability of microscopic morphology, difficulty in grasping synthesis process and technical indicators, etc., and achieve compositional Controllable, easy to control solution uniformity and stability, and conducive to large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1.1 Mix 0.5312 g of tin tetrachloride pentahydrate (SnCl 4 ∙5H 2 O), 0.0841 g of DDAB, 0.0181 g of acetamide, 0.0026 g of silver nitrate and 1.0000 g of PVP were added to a mixed solvent of 1.0 mL of ethanol and 4.0 mL of DMF, and stirred to obtain a transparent solution;

[0030] 1.2 The above solution was electrospun to obtain the precursor fiber, the spinning parameters were: positive voltage 18 KV, negative voltage 0.5 KV, receiving distance 16 cm, syringe advance speed 0.002 mm / s;

[0031] 1.3 Raise the temperature of the precursor fiber from room temperature to 600 °C at a rate of 1 °C / min, keep the temperature for 2 h, and obtain SnO after the sample is cooled with the furnace2 / Ag 2 O composite particles.

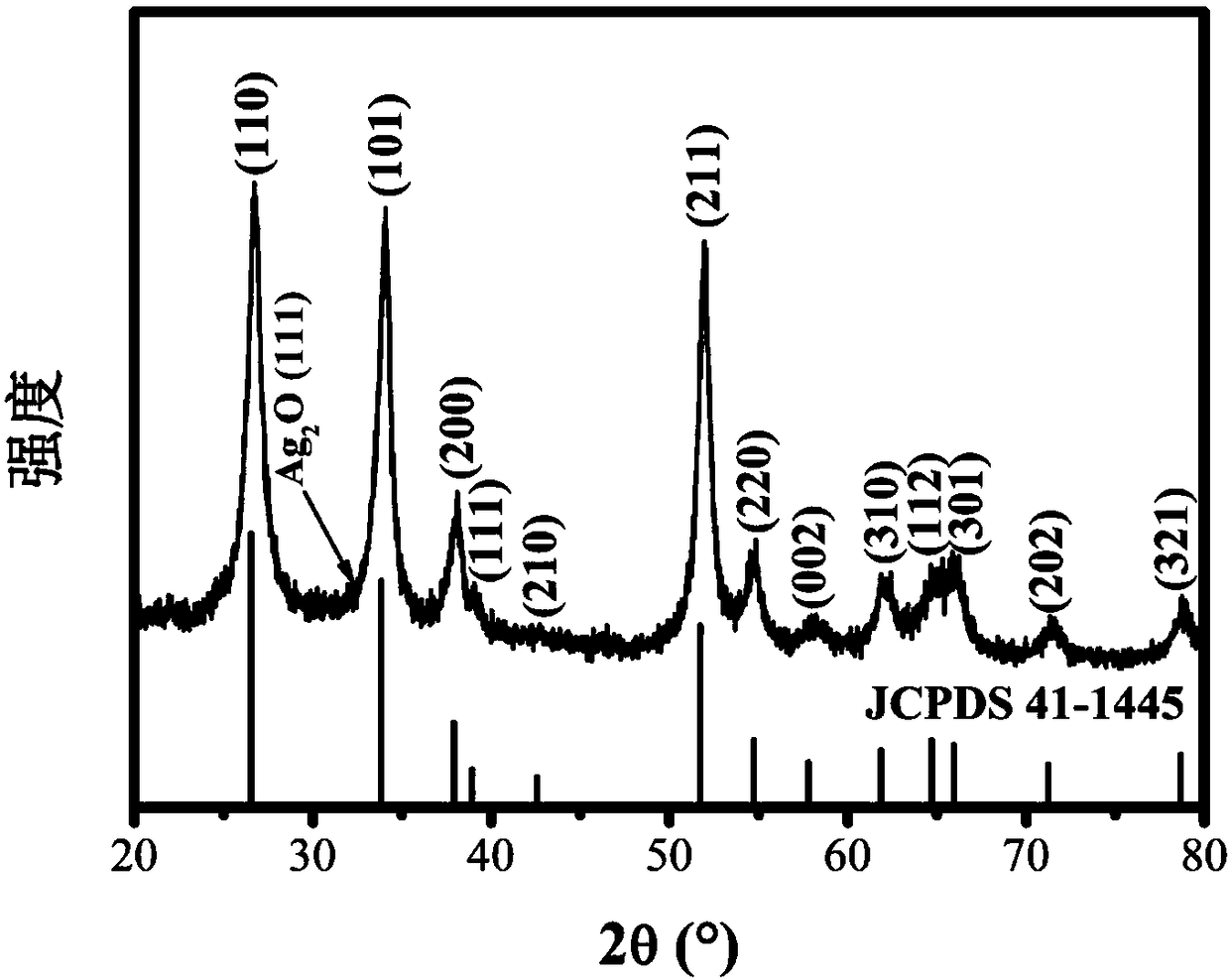

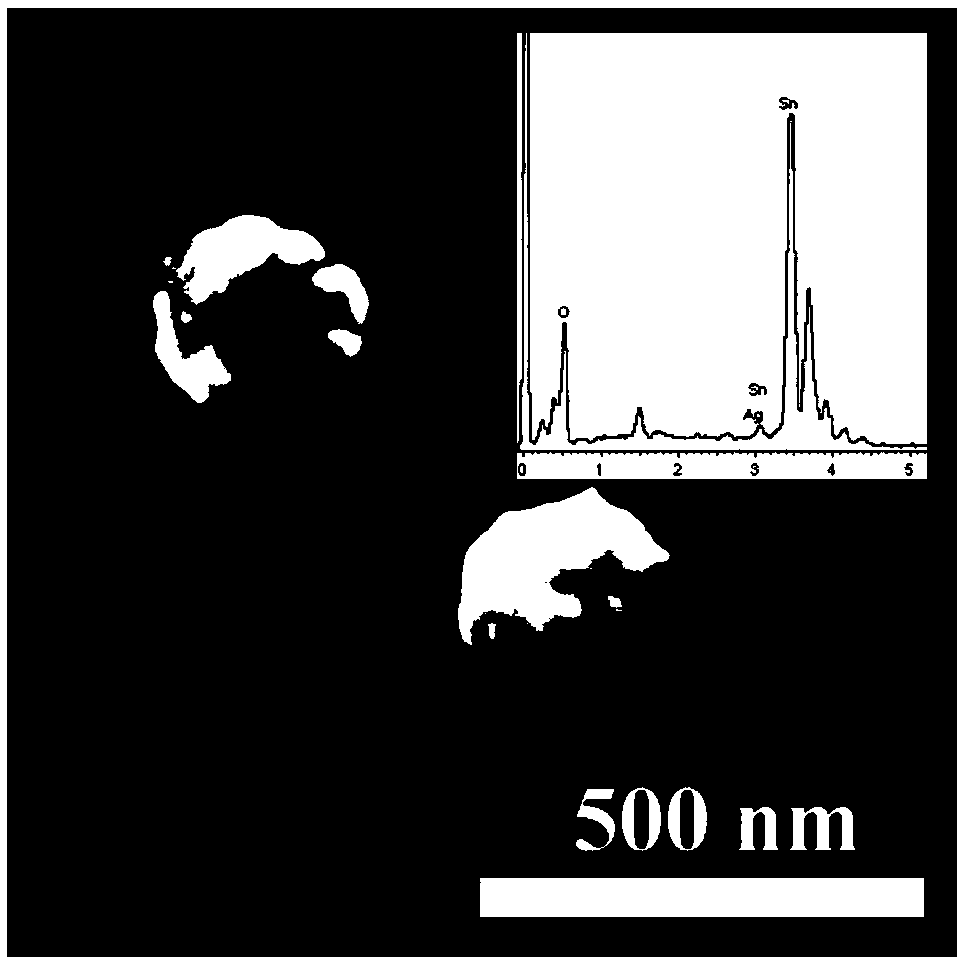

[0032] The XRD result of the product is as follows figure 1 As shown, it can be seen from the figure that all the stronger diffraction peaks are consistent with the standard XRD card (41-1445) and (41-1104), proving that the obtained product is tetragonal ...

Embodiment 2

[0034] 2.1 Add 0.1934 g of SnCl 4 ∙5H 2 O, the DDAB of 0.0689 g, the acetamide of 0.0092 g, the silver nitrate of 0.0051 g and the PVP of 0.4242 g were added in the mixed solvent of the ethanol of 1.0 mL and the DMF of 3.2 mL, stirred to obtain a transparent solution;

[0035] 2.2 The above solution was electrospun to obtain the precursor fiber, the spinning parameters were: positive voltage 16 KV, negative voltage 0.5 KV, receiving distance 19 cm, syringe advance speed 0.003 mm / s;

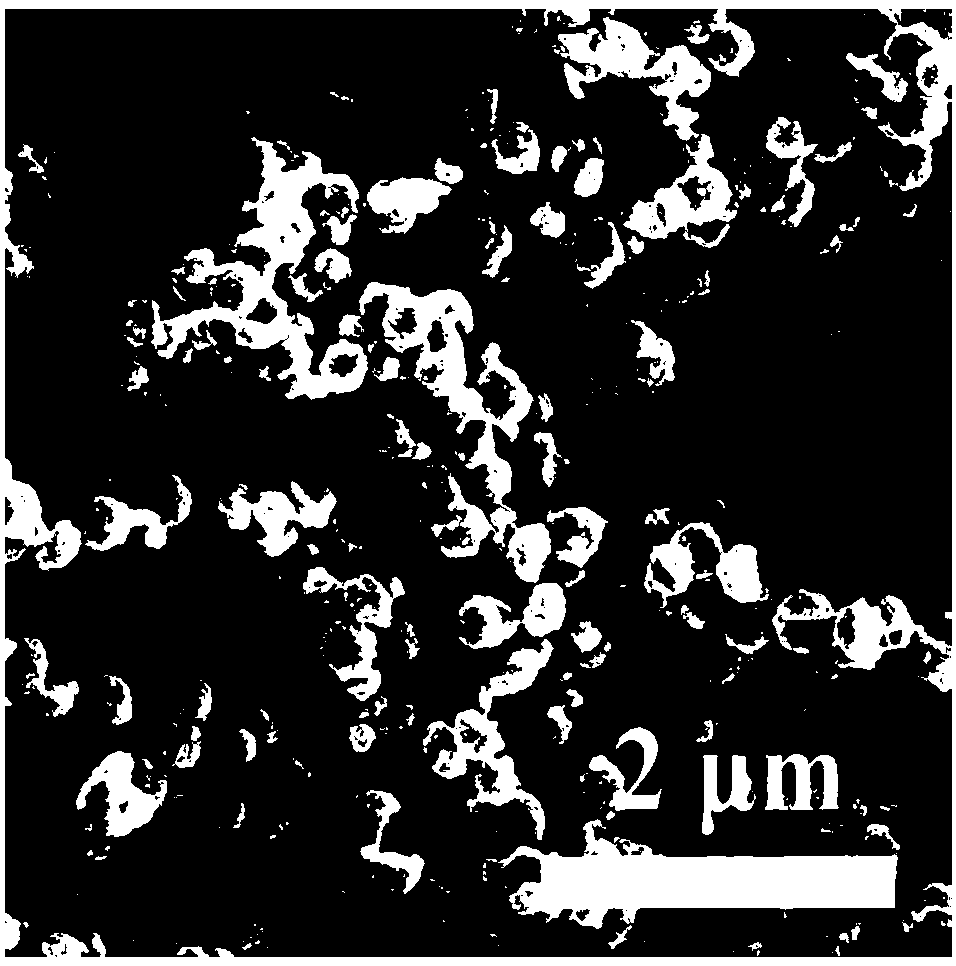

[0036] 2.3 The precursor fiber was raised from room temperature to 550 °C at a rate of 2 °C / min, and kept for 1 h. After the sample was cooled with the furnace, a spherical SnO with an average size of 0.08-0.1 μm was obtained. 2 / Ag 2 O composite particles.

Embodiment 3

[0038] 3.1 Add 0.7805 g of SnCl 4 ∙5H 2 O, the DDAB of 0.0618 g, the acetamide of 0.0159 g, the silver nitrate of 0.0113 g and the PVP of 1.3455 g were added in the mixed solvent of the ethanol of 1.0 mL and the DMF of 4.8 mL, stirred to obtain a transparent solution;

[0039] 3.2 The above solution was electrospun to obtain precursor fibers. The spinning parameters were: positive voltage 21 KV, negative voltage 0.5 KV, receiving distance 17 cm, and syringe advancing speed 0.001 mm / s;

[0040] 3.3 The precursor fiber was raised from room temperature to 700 °C at a heating rate of 3 °C / min, and kept for 6 h. After the sample was cooled with the furnace, a spherical SnO with an average size of 4.4-4.7 μm was obtained. 2 / Ag 2 O composite particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com