A strain of Lactobacillus paracasei and its application

A kind of Lactobacillus, paracheese technology, applied in the field of microorganisms, can solve the problems of nutrient loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

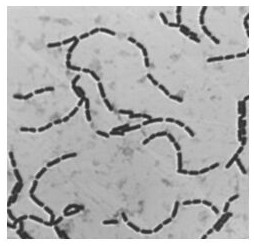

[0032] Embodiment 1: Separation and purification identification of bacterial classification

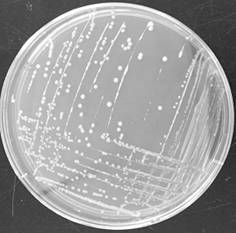

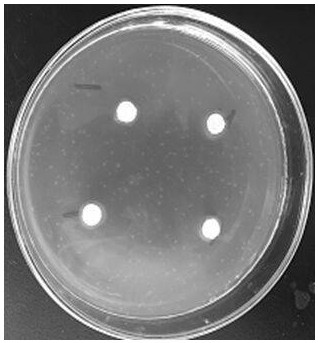

[0033] 1. Isolation and purification of strains

[0034] Weigh 10g of the collected buffalo milk sample, dilute it with normal saline, the highest dilution is 8, use the MRS solid medium with calcium carbonate for separation, and take four gradient dilution samples of 5, 6, 7, and 8 Into the inverted plate (37 ℃, 48h). According to the colony shape, size, size, color, and growth position of the culture medium (surface, interior, and bottom) of the colony, colonies with different appearance characteristics and large calcium-dissolving circles were picked and cultured on the plate for streaking and purification. Then use the same method to repeatedly streak and purify several times until the final plate has the same shape of colonies. Pick a single colony and inoculate it in MRS liquid medium for 18 hours at 37°C for storage and identification.

[0035] 2. Identification of strains ...

Embodiment 2

[0083] Example 2: Application of LSE-2014ZA001-M012-A-03(a) as a starter in the preparation of probiotic beverages

[0084](1) Acid production curve drawing: the third-generation activated LSE-2014ZA001-M012-A-03(a) was inserted into skim reconstituted milk with a protein content of 3.5% at an inoculum size of 2%, and the acidity was measured every 24 hours. The acid production curve was used to evaluate the fermentation ability of the strains. See the acid production curve of LSE-2014ZA001-M012-A-03(a) Image 6 . The results show that the acidity of LSE-2014ZA001-M012-A-03(a) can reach 176 after 24 hours of fermentation in skim reconstituted milk o T, 96h can reach 295 o T, the strain of the present invention can be used for the preparation of brown active probiotic beverages according to the production process LSE-2014ZA001-M012-A-03(a) of the brown drink production process.

[0085] (2) Preparation of parent species: Activate the 3rd generation LSE-2014ZA001-M012-A-03(a...

Embodiment 3

[0099] Example 3: Application of LSE-2014ZA001-M012-A-03(a) as a leavening agent in the preparation of Moringa yoghurt

[0100] 1. Preparation of Moringa oleifera fermentation broth

[0101] Moringa dry powder addition amount: 2.5‰ (add 2.5kg Moringa dry powder to 1 ton of Moringa yogurt)

[0102] Starter: Lactobacillus paracasei LSE-2014ZA001-M012-A-03 (a) viable count 10 9 cfu / mL

[0103] (1) Moringa powder: water: MRS culture medium = 2.5kg: 37.5kg: 12.5kg ratio for preparation.

[0104] (2) Dissolve the moringa powder with hot water at 60-70°C, refine it through a colloid mill for 10-15 minutes, until there is no agglomeration, transfer the moringa aqueous solution and nutrient solution into the strain tank and mix;

[0105] (3) Pasteurization: Raise the material in the strain tank to 88°C, start timing, and keep warm for 60 minutes after the temperature reaches the requirement;

[0106] (4) After the pasteurization is completed, cool down to 36-38°C, inoculate the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com