Bullet-proof helmet with honeycomb block structure and preparation method of bullet-proof helmet

A bulletproof helmet and honeycomb technology, applied in the direction of chemical instruments and methods, applications, layered products, etc., can solve the problems of large overall deformation, no protective performance, low density, etc., to improve the bulletproof protection effect, easy to carry and wear , the effect of small overall deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

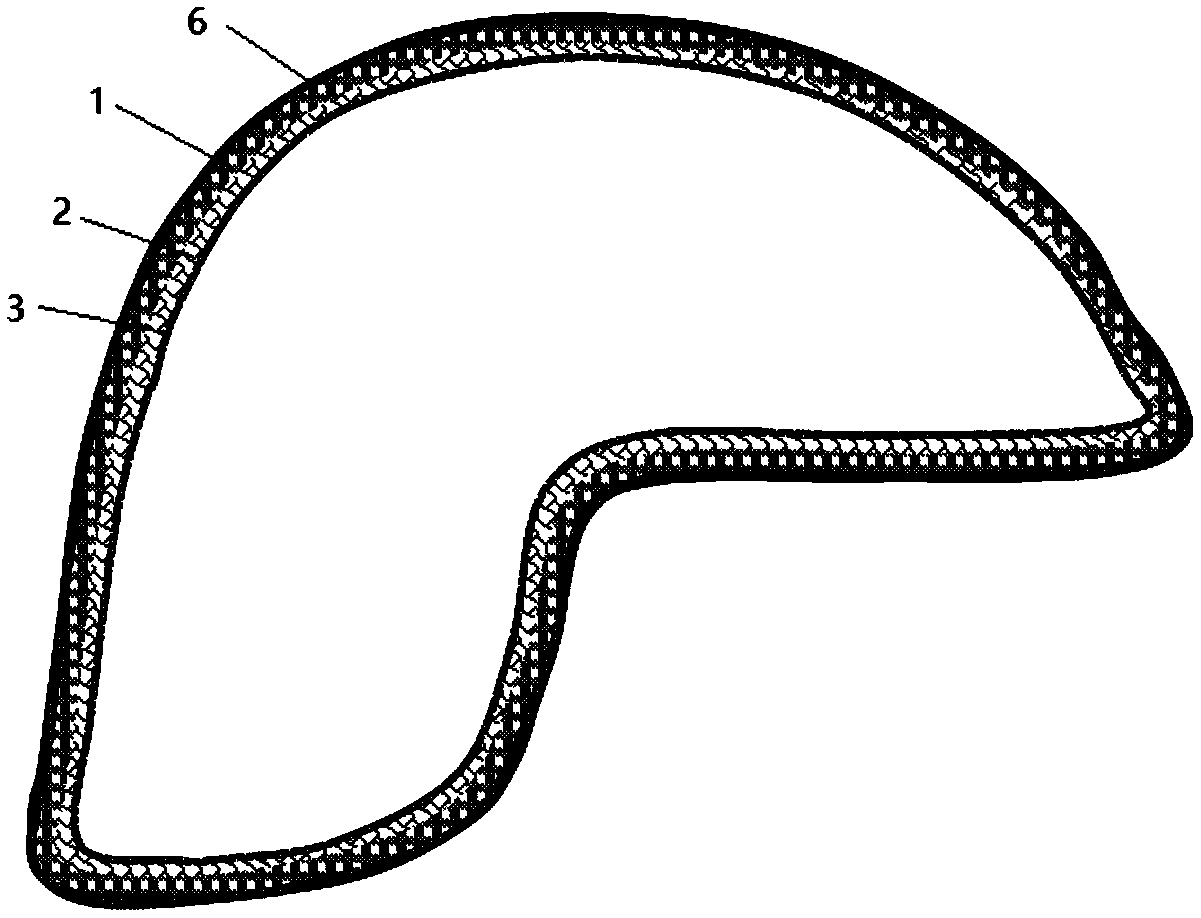

[0036] On the other hand, the present invention also provides a kind of preparation method of above-mentioned honeycomb barrier structure ballistic helmet, comprises the following steps:

[0037] Firstly, the two-dimensional fabric of high-strength fiber is impregnated with composite thermoplastic resin, which is laminated by cutting technology, and the inner buffer layer helmet shell is formed by molding process; the high-strength carbon fiber two-dimensional fabric is impregnated with composite thermosetting resin matrix to form a pre- Immerse the raw material, also use the cutting technology to stack the layers and prepare the middle rigid layer on the outer layer of the inner buffer layer helmet shell by compression molding. The maximum pressing pressure used is 25MPa, and the hot pressing temperature of the buffer layer is in the range of 120-140°C. The hot pressing temperature of the rigid layer is controlled within the range of 120-160°C.

[0038]Further, both the middl...

Embodiment 1

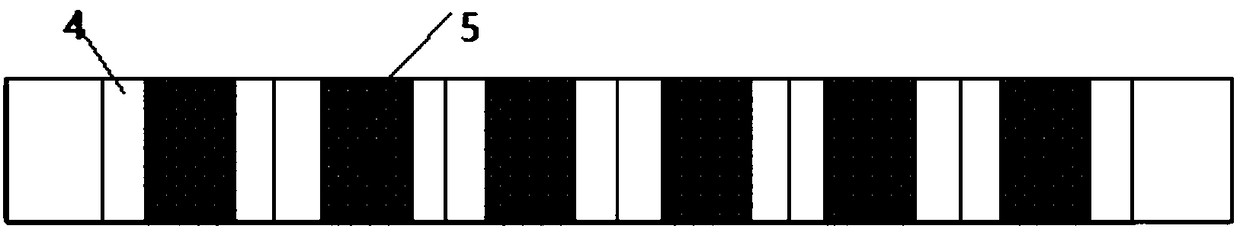

[0041] Select the plain weave prepreg raw material of UHMWPE fiber with 20% polyurethane resin content, use specific cutting technology to laminate the layers, adopt hot pressing molding, and press at 120°C and 25MPa pressure for 1 hour to complete the cushioning with a thickness of 3mm The preparation of the inner shell of the multi-layer helmet; on the outside of the buffer layer, the plain T300 high-strength carbon fiber is used to impregnate the epoxy resin with a content of 60% to form a pre-impregnated raw material, which is laminated by a specific cutting technology, and hot-pressed to 160 ℃ temperature, 25MPa pressure for 1 hour to complete the preparation of the buffer layer helmet inner shell with a thickness of 2mm; use alumina ceramics to prepare a hexagonal columnar ceramic microtube with a thickness of 1mm, a maximum diagonal length of 20mm, and a height of 5mm. The hexagonal columnar ceramic microtube is spliced with epoxy resin adhesive at 40°C to complete the...

Embodiment 2

[0043] The twill prepreg raw material of aramid fiber with a polyethylene resin content of 40% is selected, laminated and laminated by a specific cutting technology, and hot-pressed, and pressed at a temperature of 120°C and a pressure of 15MPa for 2 hours to complete a thickness of 2mm. The preparation of the inner shell of the cushioning layer helmet; on the outside of the cushioning layer, satin T700 high-strength carbon fiber is used to impregnate 30% epoxy resin to form a pre-preg raw material, which is laminated by specific cutting technology and hot-pressed. , with a temperature of 125°C and a pressure of 20MPa for 1 hour to complete the preparation of the buffer layer helmet inner shell with a thickness of 2.5mm; using silicon carbide ceramics to prepare a hexagonal column with a thickness of 2mm, a maximum diagonal length of 10mm, and a height of 10mm Ceramic microtubes, the hexagonal columnar ceramic microtubes are spliced with acrylic resin adhesives at 40°C to com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com