Testing device and testing method of sulfur-resisting and water-resisting performance of low-temperature flue gas denitrification catalyst for cement kiln

A technology of denitrification catalyst and low-temperature flue gas, which is applied in the direction of chemical analysis by means of catalysis, can solve problems such as difficult to realize industrial application, no control, catalyst poisoning and deactivation, and achieve excellent anti-sulfur and anti-water intoxication performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

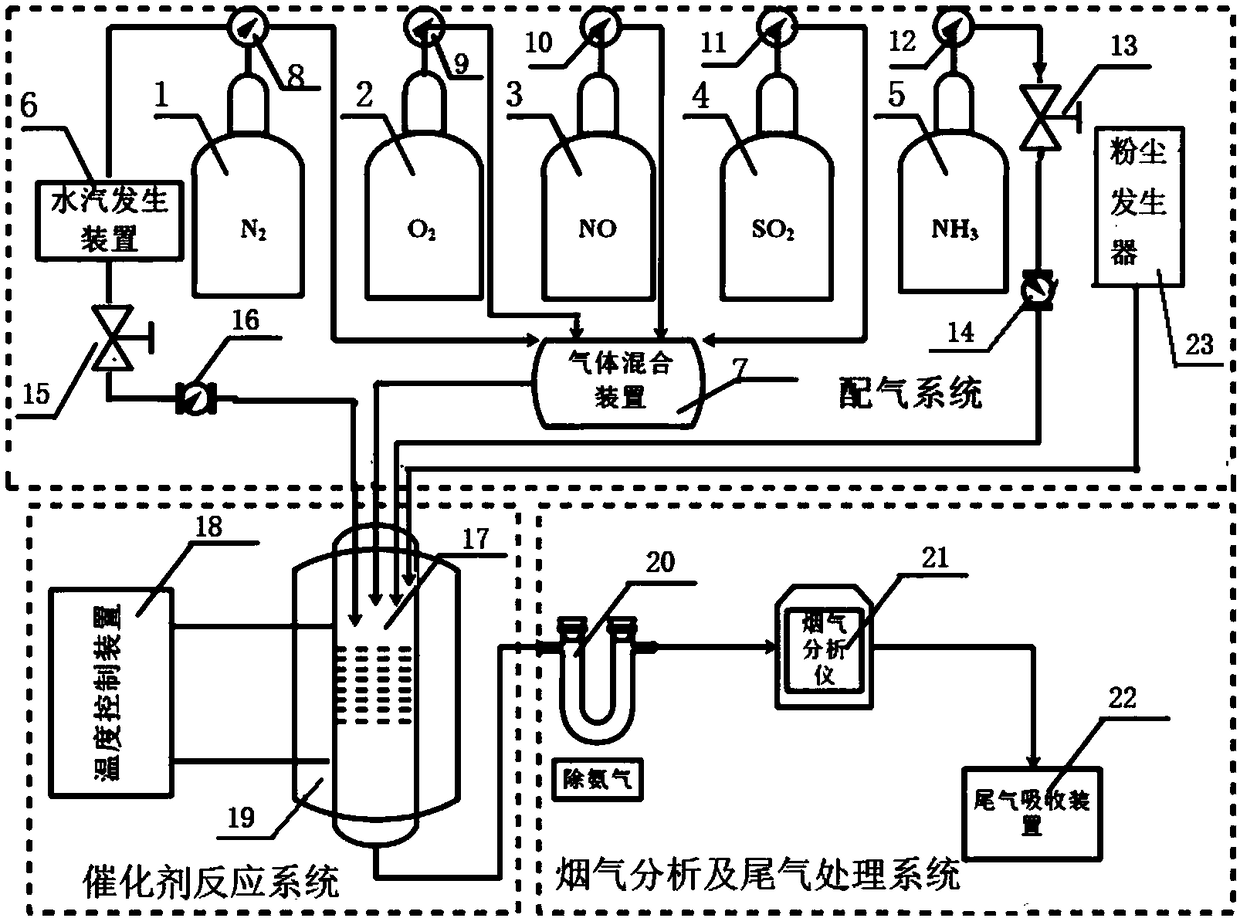

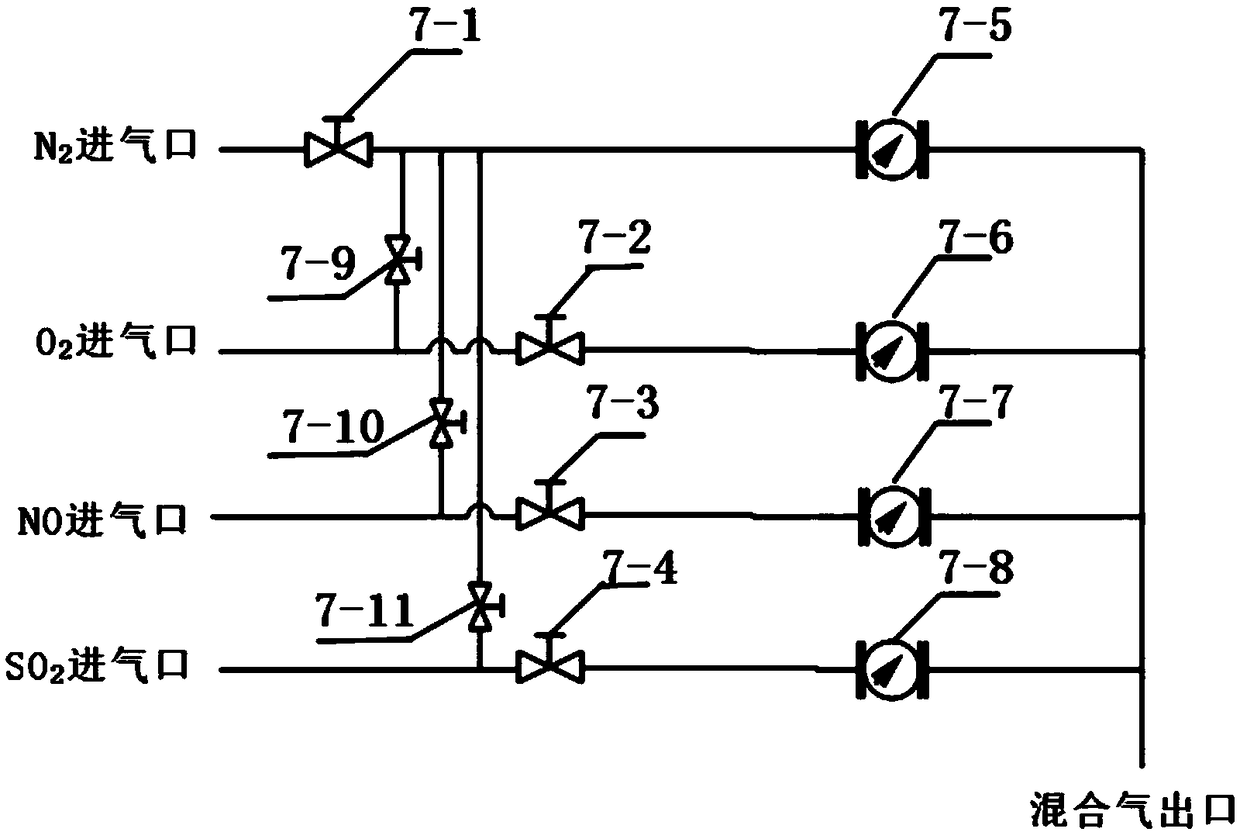

[0057] Place 2ml of the catalyst to be tested in the catalyst reactor 17, open the nitrogen gas inlet unit 1, and open the gas flow control valve 7-1, slowly feed nitrogen into the catalyst reaction system, and use the nitrogen pressure reducing valve 8 to stabilize the pressure At about 0.4MPa, keep it stable for 10 minutes, then use the method of brushing neutral foaming agent to check for leaks at all sealing points, and the next test can only be carried out after the leak test is qualified.

[0058] Open the oxygen intake unit 2 and the nitric oxide intake unit 3, and open the gas circulation control valves 7-2, 7-3, so that the oxygen and nitric oxide gases pass through the pressure reducing valves 9, 10 and the gas mixing device 7. Into the catalyst reactor 17, open the ammonia gas intake unit 5, pass through the pressure reducing valve 12, the gas circulation control valve 13, the mass flow meter 14 and then pass into the catalyst reactor 17, the gas composition is 800pp...

Embodiment 2

[0060] Place 2ml of the catalyst to be tested in the catalyst reactor 17, open the nitrogen gas inlet unit 1, and open the gas flow control valve 7-1, slowly feed nitrogen into the catalyst reaction system, and use the nitrogen pressure reducing valve 8 to stabilize the pressure At about 0.4MPa, keep it stable for 10 minutes, then use the method of brushing neutral foaming agent to check for leaks at all sealing points, and the next test can only be carried out after the leak test is qualified.

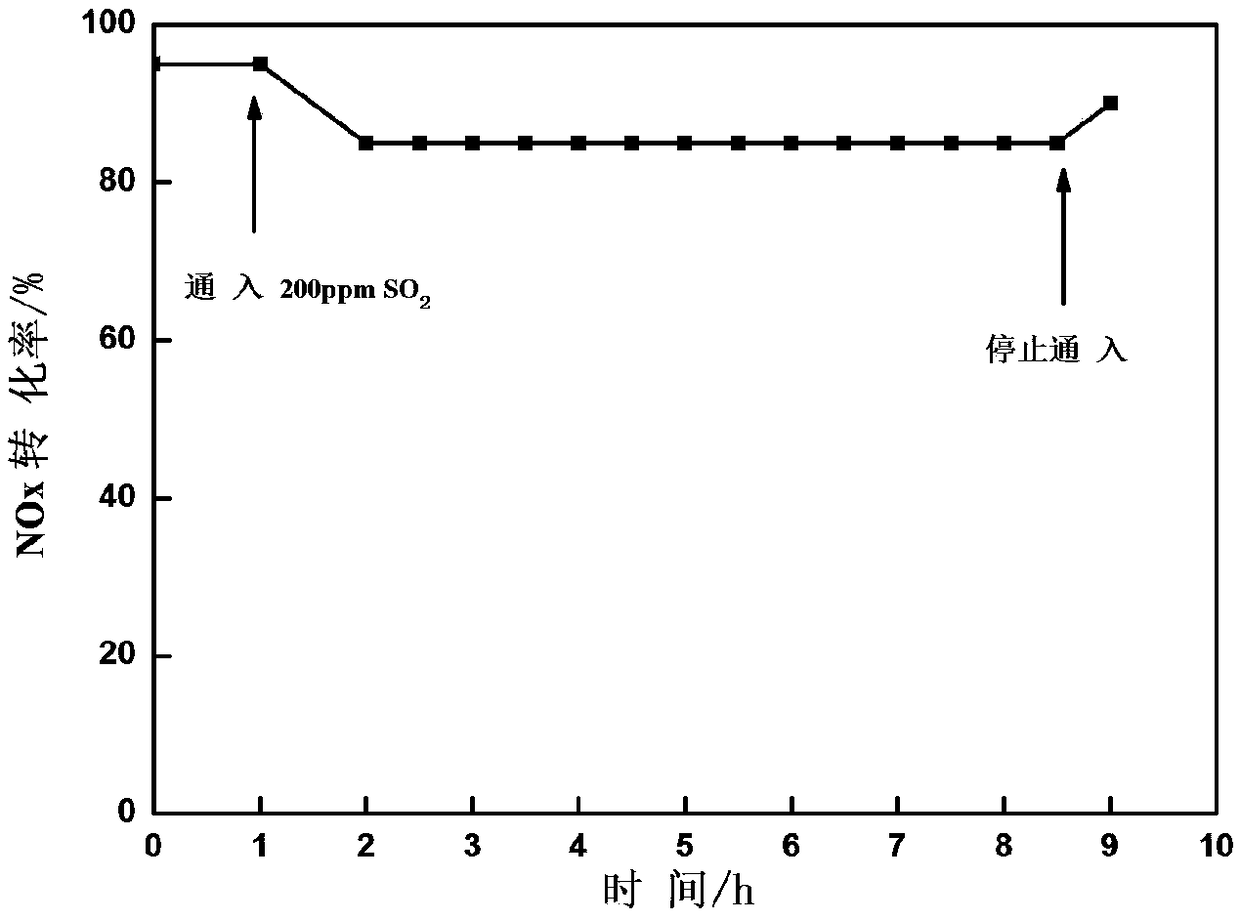

[0061] Open the oxygen intake unit 2 and the nitric oxide intake unit 3, and open the gas circulation control valves 7-2, 7-3, so that the oxygen and nitric oxide gases pass through the pressure reducing valves 9, 10 and the gas mixing device 7. Enter in the catalyst reactor 17, open the ammonia gas intake unit 5, pass in the catalyst reactor 17 after the pressure reducing valve 12, the gas circulation control valve 13, the mass flow meter 14, open the ammonia gas intake unit 5, After...

Embodiment 3

[0063] Place 2ml of the catalyst to be tested in the catalyst reactor 17, open the nitrogen gas inlet unit 1, and open the gas flow control valve 7-1, slowly feed nitrogen into the catalyst reaction system, and use the nitrogen pressure reducing valve 8 to stabilize the pressure At about 0.4MPa, keep it stable for 10 minutes, then use the method of brushing neutral foaming agent to check for leaks at all sealing points, and the next test can only be carried out after the leak test is qualified.

[0064] Open the oxygen intake unit 2 and the nitric oxide intake unit 3, and open the gas circulation control valves 7-2, 7-3, so that the oxygen and nitric oxide gases pass through the pressure reducing valves 9, 10 and the gas mixing device 7. Enter in the catalyst reactor 17, open the ammonia gas intake unit 5, pass in the catalyst reactor 17 after the pressure reducing valve 12, the gas circulation control valve 13, the mass flow meter 14, open the ammonia gas intake unit 5, After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com