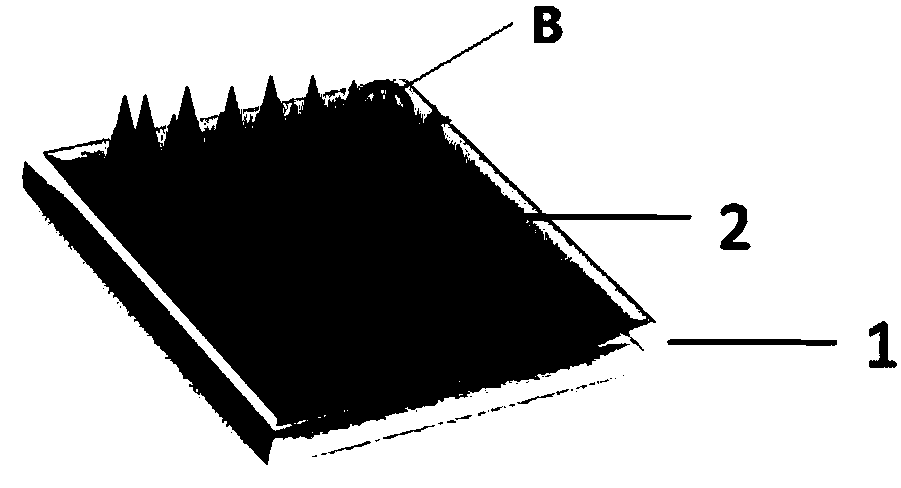

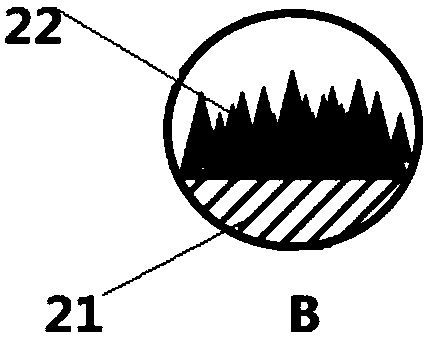

Graphene-based field emission cold cathode and preparation method

A cold cathode and field emission technology, which is applied in cold cathode manufacturing, electron emission electrode/cathode, cold cathode, etc., can solve the problem of large-area and uniform growth of graphene films, the influence of film uniformity and contact tightness, and reduce field emission. Performance and other issues, to achieve the effect of avoiding shielding effect, stable structure, and large emission current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

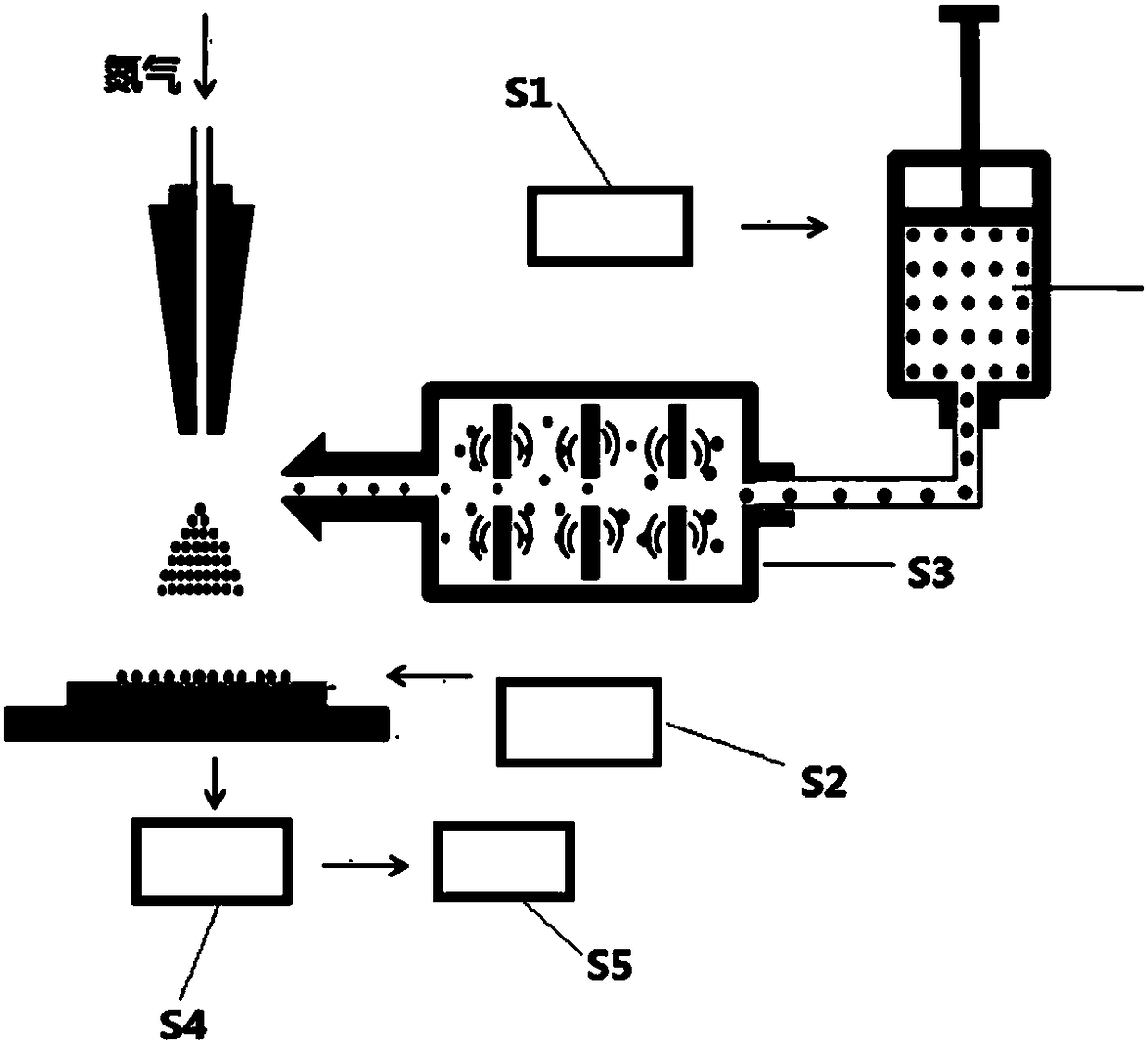

[0045] This embodiment provides a method for preparing a field emission cold cathode, the process is as follows:

[0046] 1) Cathode substrate cleaning

[0047] A 1cmx1cm N-type Si sheet was ultrasonically cleaned with deionized water for 10 minutes, transferred to a mixture of ammonia water, hydrogen peroxide and deionized water for 10 minutes, and then ultrasonically cleaned with deionized water for 10 minutes; transferred to hydrochloric acid, hydrogen peroxide and deionized water. Ultrasonic cleaning in deionized water mixture for 10 minutes, then ultrasonic cleaning in deionized water for 10 minutes, nitrogen blow-drying; transfer to absolute ethanol for 10 minutes ultrasonic cleaning, nitrogen blow-drying for later use.

[0048] 2) Preparation of graphene dispersion

[0049] Mix graphene and organic solution ethanol in a certain mass ratio (1:50) and disperse evenly by ultrasonic, and add a small amount of ethyl cellulose (10:1 mass ratio to graphene) and terpineol (mas...

Embodiment 2

[0061] This embodiment provides a method for preparing a field emission cold cathode, the process is as follows:

[0062] 1) Cathode substrate cleaning

[0063] A 2.2cmx2.2cm N-type Si sheet was ultrasonically cleaned with a mixture of ammonia water, hydrogen peroxide and deionized water; after ultrasonic cleaning with ethanol and deionized water respectively, it was blown dry with nitrogen.

[0064] 2) Preparation of graphene dispersion

[0065] Mix graphene and isopropanol in a certain mass ratio (1:200) and ultrasonically disperse for 10 minutes, add ethyl cellulose (mass ratio to graphene: 2:1) and terpineol (mass ratio to graphene: 1:1), ultrasonic dispersion and dissolution, and continuous stirring to remove excess organic solution to form a graphene dispersion.

[0066] 3) Atomization and spraying

[0067] Spray the micron-sized graphene atomized droplets ultrasonically atomized under 6W power with a flow rate of 600sccm nitrogen to the surface of the substrate fixed...

Embodiment 3

[0074] This embodiment provides a method for preparing a field emission cold cathode, the process is as follows:

[0075] 1) Cathode substrate cleaning

[0076] After the 0.7cmx0.7cm metal sheet was ultrasonically cleaned with ammonia water, ethanol, deionized water and absolute ethanol, it was blown dry with nitrogen gas for later use.

[0077] 2) Preparation of graphene dispersion

[0078] Mix graphene and isopropanol in a certain mass ratio (1:300) and then ultrasonically disperse, add ethyl cellulose (mass ratio to graphene: 20:1) and terpineol (mass ratio to graphene: 4 : 1), ultrasonically disperse and dissolve, heat and stir to form a graphene dispersion.

[0079] 3) Atomization and spraying

[0080] ①Put the graphene dispersion into the syringe, inject it into the ultrasonic atomization pool at a certain speed through the hose, and perform ultrasonic atomization at a power of 9W;

[0081] ② Spray micron-sized graphene atomized droplets onto the surface of the subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com