A kind of nanofiltration membrane and its application

A technology of nanofiltration membrane and filter layer, applied in the field of nanofiltration membrane, can solve the problems of increased cost, poor selectivity, and increased operating pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

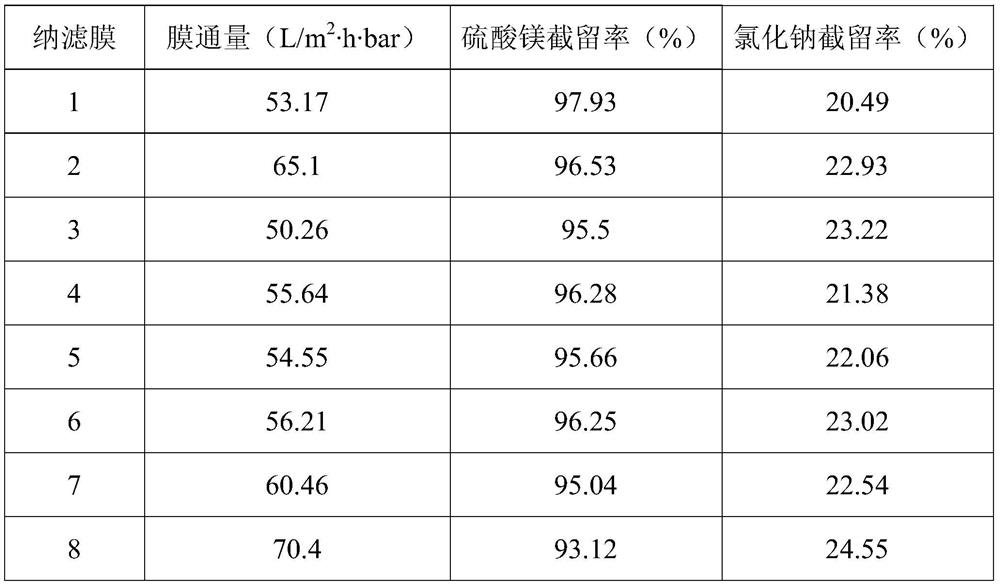

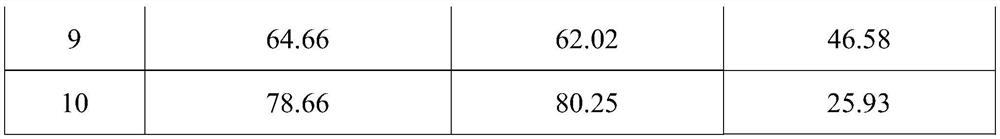

Examples

Embodiment 1

[0039] Nanofiltration membrane 1 was prepared by the following steps:

[0040] In step (1), take an area of 10cm×10cm and a weight of 25g / m 2 Polyethylene terephthalate non-woven fabric, on one side of the non-woven fabric, use electrospinning equipment to deposit a layer of electrospun polyacrylonitrile nanofibers with a weight of 1g and a diameter of 150nm to obtain a base layer, and in the base layer The electrospun nanofiber layer is a porous structure with a pore size of 100 nm;

[0041] Step (2), one layer of bamboo fibrous dispersion liquid is coated on the side surface containing electrospun nanofibers of the base layer obtained in step (1), and the cellulose nanofiber layer with a weight of 0.1g is obtained after the solvent volatilizes naturally , wherein the cellulose nanofibers have a diameter of 50nm and a length of 5000nm;

[0042] Step (3), 10g number-average molecular weight is 500000Da polyethyleneimine, 0.8g anhydrous piperazine and 0.4g triethylamine are d...

Embodiment 2

[0044] Nanofiltration membrane 2 was prepared by the following steps:

[0045] The only difference with Example 1 is that the non-woven fabric used in step (1) has a grammage of 40g / m 2 The polyimide non-woven fabric, the electrospun nanofibers are electrospun polyvinyl alcohol nanofibers with a diameter of 300nm, and the obtained electrospun nanofiber layer has a porous structure with a pore diameter of 870nm.

[0046] Embodiment 2 obtains nanofiltration membrane 2.

Embodiment 3

[0048] Nanofiltration membrane 3 was prepared by the following steps:

[0049] The difference from Example 1 is that step (2) is to use electrospinning method to use cellulose cuproammonia solution as raw material to spin on the base layer to prepare a cellulose nanofiber layer, wherein the cellulose nanofiber diameter is 5nm, The length is 200nm.

[0050] Embodiment 3 obtains nanofiltration membrane 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com