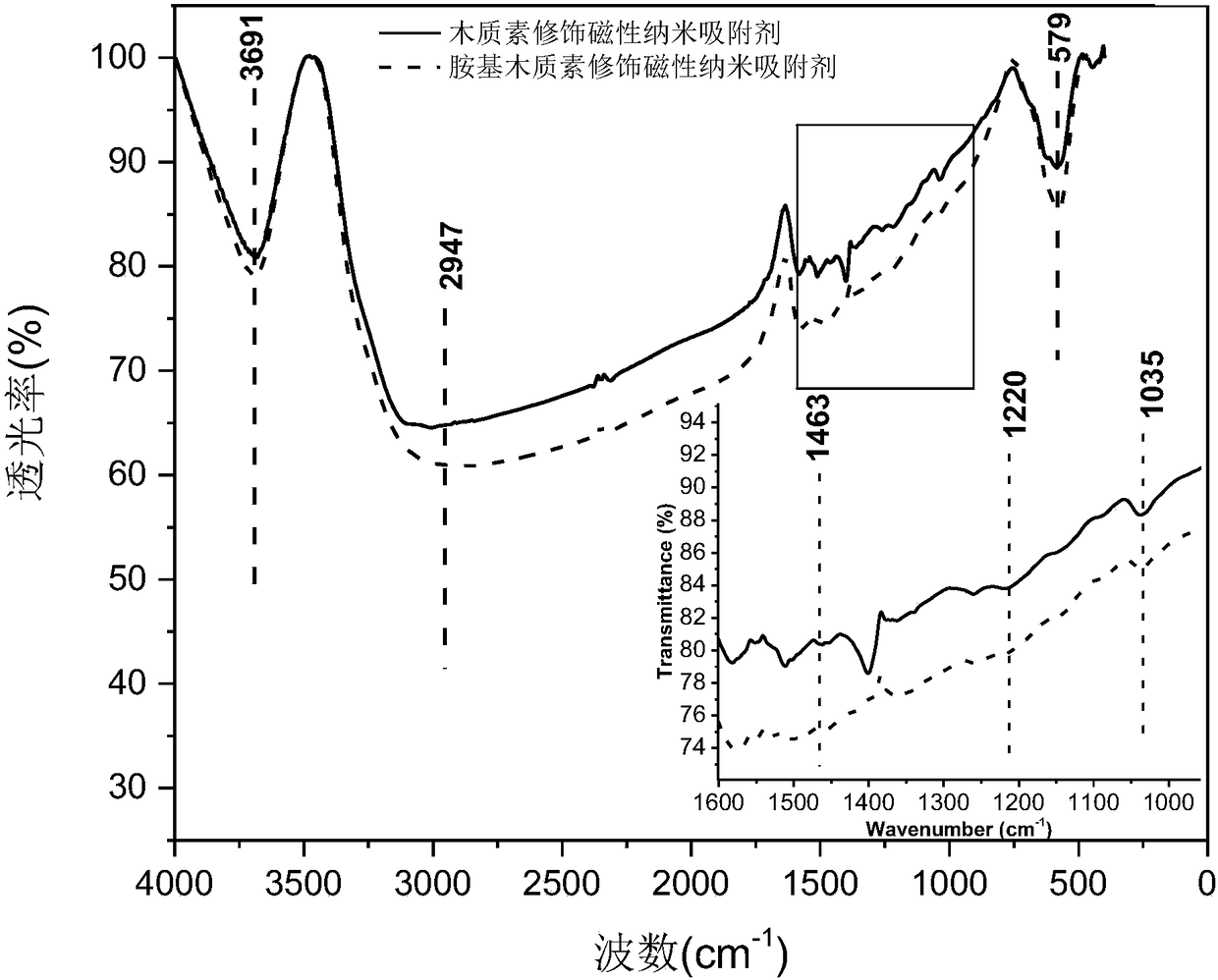

Preparation and application of lignin or aminolignin-modified magnetic nano-adsorbent

A magnetic nano- and nano-adsorption technology, which is applied in the direction of adsorption of water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of low saturated adsorption capacity and difficult separation, and achieve high saturated adsorption capacity, Effect of high magnetic response and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In order to achieve the above purpose, the present invention provides a novel lignin and its amine derivatives modified on Fe 3 o 4 A green synthesis method on the surface of nanoparticles, and using the synthesized magnetic nano-adsorbent for the adsorption treatment of dyes in water pollution, the preferred preparation method is as follows:

[0035] (1) Take FeCl 3 ·6H 2 O and FeCl 2 4H 2 Dissolve O in deionized water, pass nitrogen protection into the reaction vessel, stir mechanically and heat in a water bath at 50-75°C for 0.1-2h;

[0036] (2) Dissolving lignin or amino lignin in 5%wt ammonia water, drop by drop into the reaction system;

[0037] (3) Add 5% ammonia water drop by drop, control the pH of the system at 9-12, and continue the reaction for 2 hours;

[0038] (4) After the reaction is finished, cool at room temperature, separate by magnetic attraction to obtain a solid product, wash 3 times with deionized water, and dry in a freeze dryer to obtain t...

Embodiment 1

[0043] A kind of synthetic method of lignin modified magnetic nano-adsorbent, the steps are as follows:

[0044] (1) Take 5g of FeCl 3 ·6H 2 O and 2g FeCl 2 4H 2 O was dissolved in 1000ml of deionized water, nitrogen protection was introduced into the reaction vessel, mechanically stirred and heated in a water bath at 65°C.

[0045] (2) Dissolve 2g of lignin or amino lignin in 100ml of 5wt% ammonia water, and drop into the reaction system drop by drop.

[0046] (3) Add 5% ammonia water drop by drop, control the pH of the system at 9-12, and continue the reaction for 2 hours.

[0047] (4) After the reaction is finished, cool at room temperature, separate by magnetic attraction to obtain a solid product, wash 3 times with deionized water, and dry in a freeze dryer to obtain the product.

Embodiment 2

[0049] A kind of synthetic method of lignin modified magnetic nano-adsorbent, the steps are as follows:

[0050] (1) Take 5g of FeCl 3 ·6H 2 O and 2g FeCl 2 4H 2 O was dissolved in 1000ml of deionized water, nitrogen protection was introduced into the reaction vessel, mechanically stirred and heated in a water bath at 70°C.

[0051] (2) Dissolve 1 g of lignin or amino lignin in 100 ml of pH=13 NaOH aqueous solution, and drop into the reaction system drop by drop.

[0052] (3) Then add pH=13 NaOH aqueous solution drop by drop, control the pH of the system at 9-12, and continue the reaction for 2 hours.

[0053] (4) After the reaction is finished, cool at room temperature, separate by magnetic attraction to obtain a solid product, wash 3 times with deionized water, and dry in a freeze dryer to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com