High-purity barium hydroxide production wastewater recycling technology and equipment

A barium hydroxide and waste water technology, applied in calcium/strontium/barium oxide/hydroxide, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve low resource utilization, high-quality poisonous and heavy mineral resources Depletion, difficult recycling and other issues, to achieve good economic and environmental benefits, improve wastewater treatment efficiency, and reduce resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

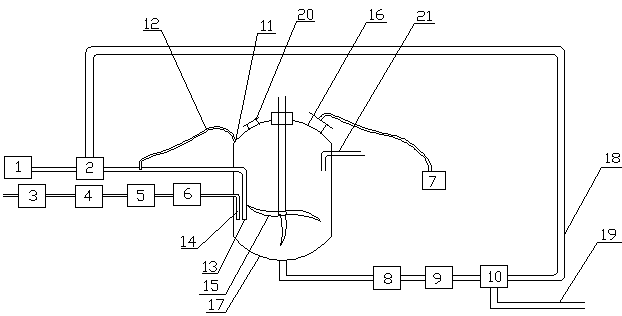

Image

Examples

Embodiment 1

[0044] Embodiment 1: the waste water of producing high-purity barium hydroxide is separated by the separator behind the barium hydroxide reactor, and waste water is pumped into the barium chloride reactor, and simultaneously in the barium chloride reactor by mass ratio waste water: sodium bicarbonate is 7:0.1, add sodium bicarbonate, stir with the stirrer for 5 minutes, pump tap water, hydrochloric acid and barium carbonate according to the mass ratio of tap water:hydrochloric acid:barium carbonate at 4:0.5:1.8, stir with the stirrer for 10min, and output to the filter for filtration. The filtrate is pumped into the lye reaction kettle, and the filtrate by mass ratio: sodium hydroxide is 15:8 and sodium hydroxide is added, stirred and reacted for 5 minutes, and the material is fed to the centrifuge for centrifugation, and the centrifuged mother liquor is pumped into the separator through the mother liquor discharge pipe. The high-purity barium hydroxide finished product is disc...

Embodiment 2

[0047] Embodiment 2: the waste water of producing high-purity barium hydroxide is separated by the separator behind the barium hydroxide reactor, and waste water is pumped into the barium chloride reactor, and simultaneously in the barium chloride reactor by mass ratio waste water: sodium bicarbonate is 7:0.2, add sodium bicarbonate, stir with the agitator for 10 minutes, pump tap water, hydrochloric acid and barium carbonate according to the mass ratio of tap water: hydrochloric acid: barium carbonate at 5:1:2.5, stir with the agitator for 30 minutes, and output to the filter for filtration. The filtrate is pumped into the lye reaction kettle, and the filtrate by mass ratio: sodium hydroxide is 20:15 and sodium hydroxide is added, stirred and reacted for 20min, and the material is fed to the centrifuge for centrifugation, and the centrifuged mother liquor is pumped into the separator through the mother liquor discharge pipe. The high-purity barium hydroxide finished product is...

Embodiment 3

[0050] Embodiment 3: the waste water of high-purity barium hydroxide is separated by the separator behind barium hydroxide reactor, waste water is pumped into barium chloride reactor, simultaneously in barium chloride reactor by mass ratio waste water: sodium bicarbonate is 7 : 0.14, add sodium bicarbonate, stirrer stirs after 8min, tap water: hydrochloric acid: barium carbonate is 4.5:0.6:2 by mass ratio tap water, hydrochloric acid and barium carbonate are pumped in, stirrer stirs 25min, output to filter and filter, filtrate Pump into the lye reaction kettle, add sodium hydroxide according to the mass ratio of filtrate: sodium hydroxide is 20:10, stir and react for 10 minutes, discharge the material to the centrifuge, and the centrifuged mother liquor is pumped into the separator through the mother liquor discharge pipe, and the high-purity hydrogen The barium oxide finished product is discharged through the finished product discharge pipe.

[0051] The stirring speed of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com