Method of preparing humus and recovering heavy-metal-polluted bottom mud with humus

A technology for polluting sediment and humus, applied in water pollutants, sludge treatment, chemical instruments and methods, etc., to achieve low cost, low heavy metal concentration and potential toxicity, and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

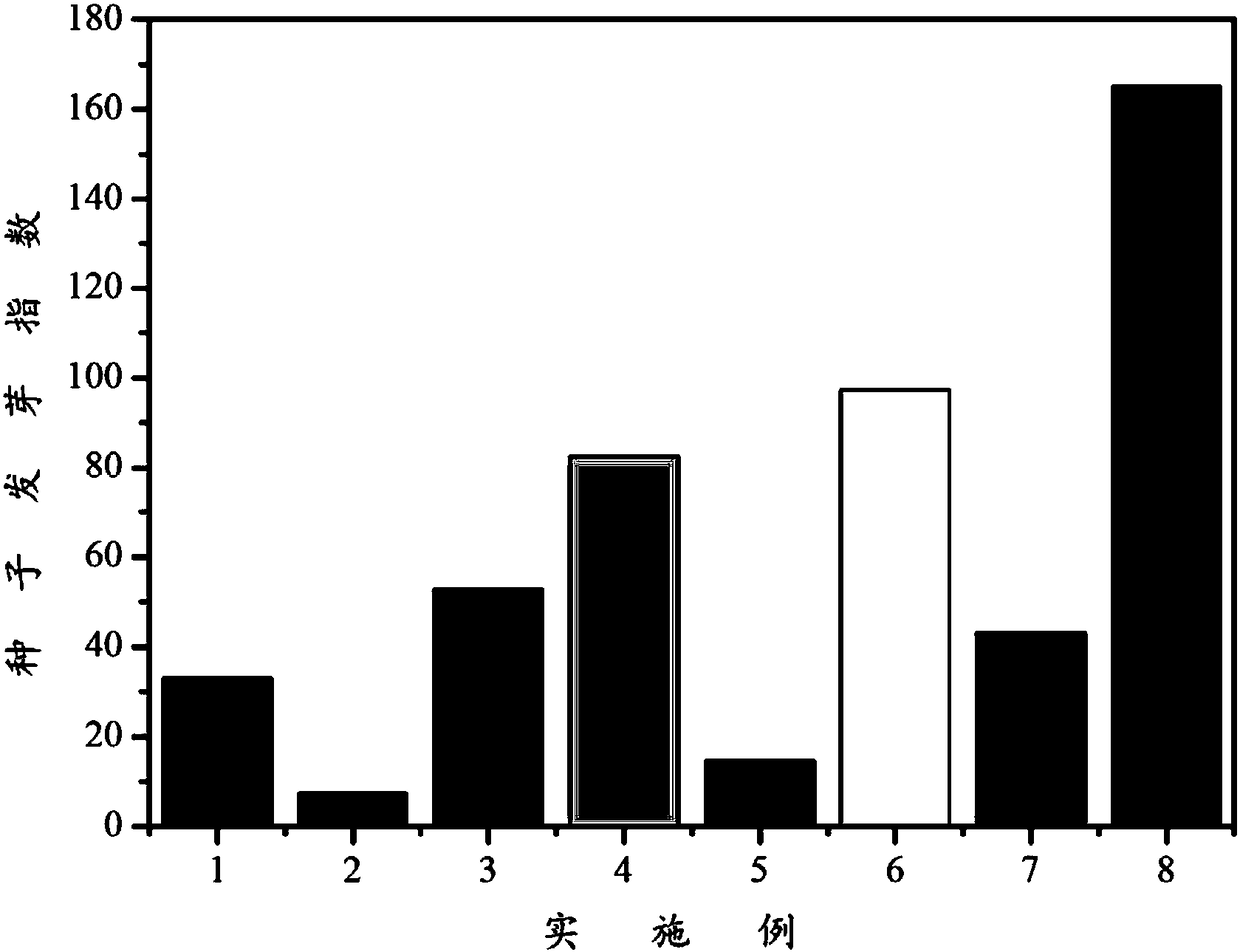

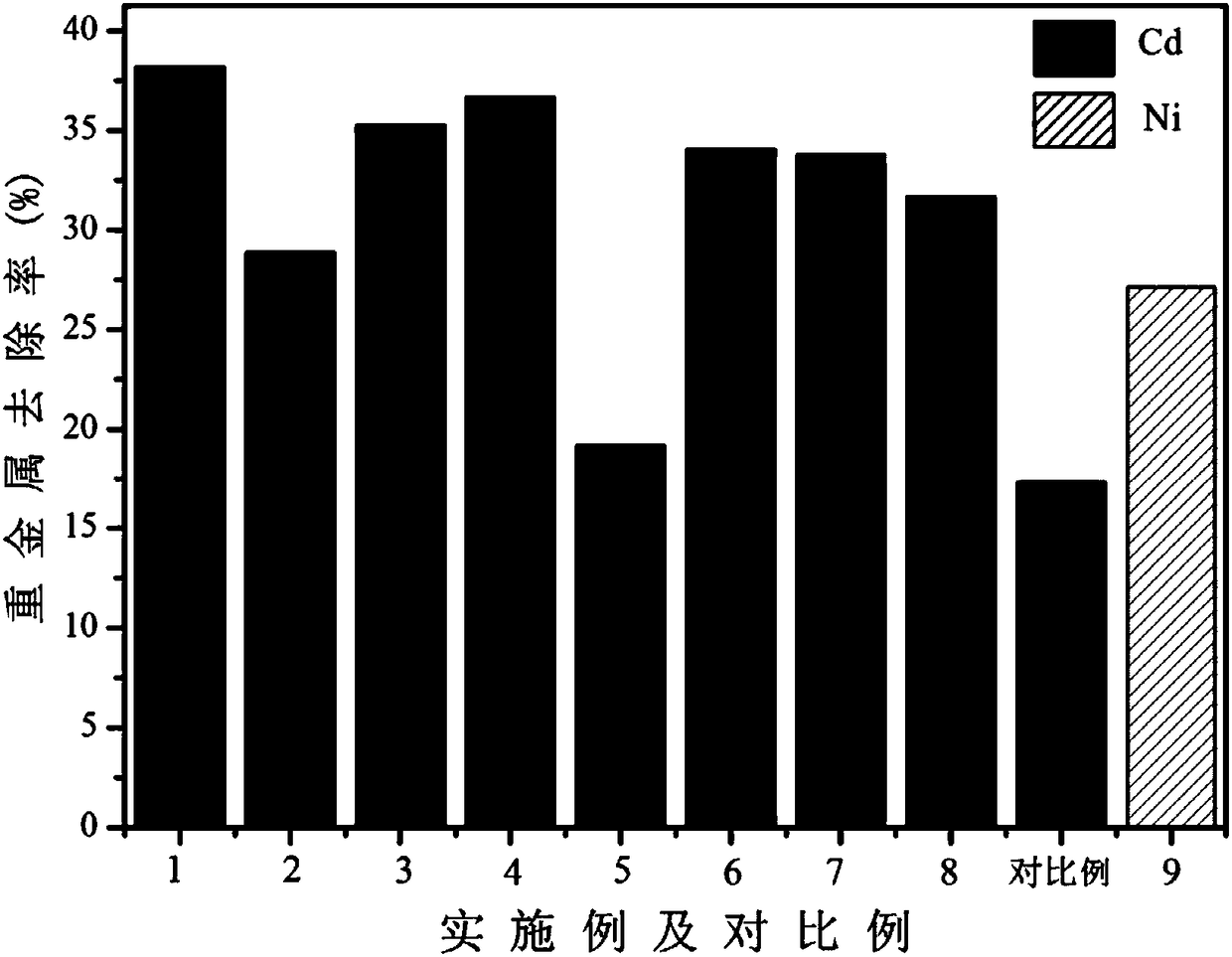

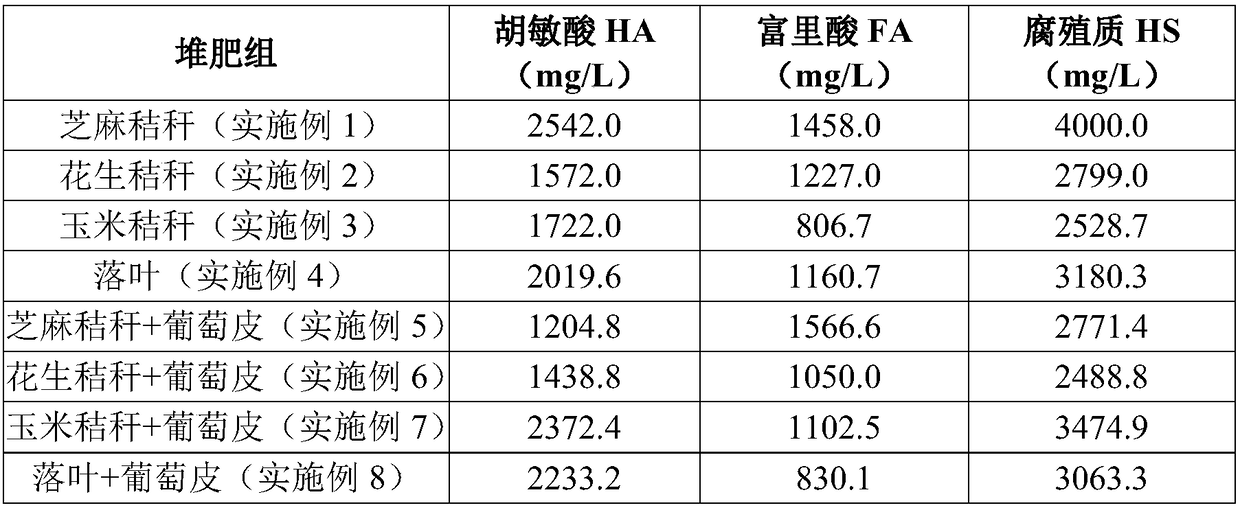

Examples

Embodiment 1

[0042] A method for preparing humus and repairing heavy metal contaminated bottom sludge, specifically using sesame straw compost to produce humus and leaching and repairing heavy metal bottom sludge, including the following steps:

[0043] 1. Compost design and humus extraction:

[0044] A. Use a 50L plastic box to perform composting experiments in aerobic composting mode. Five holes are evenly drilled on the lid of the plastic box, and 40mm thick foam is attached to the surface of the box body to reduce heat loss. According to a certain ratio of composting raw materials (sesame straw: sawdust: soybean meal: humus: grape pomace = 5: 2: 1: 2:0), adjust the pile body C / N to 25 with urea, and adjust the moisture content to 60%, inoculate 50mL mixed bacteria per kg of compost raw materials, spore suspension 2×10 6 ML -1 Among them, white rot fungi accounted for 60%, green wood enzyme accounted for 40%, aerobic composting for 60 days, turning the pile twice a week;

[0045] B. After co...

Embodiment 2

[0052] A method for preparing humus and repairing heavy metal contaminated bottom sludge, specifically using peanut straw compost to produce humus and leaching and repairing heavy metal bottom sludge, including the following steps:

[0053] 1. Compost design and humus extraction:

[0054] A. Use a 50L plastic box to conduct composting experiments in aerobic composting mode. Five holes are evenly drilled on the lid of the plastic box, and 40mm thick foam is attached to the surface of the box body to reduce heat loss. According to the mass ratio of composting raw materials: peanut stalks: wood chips: soybean meal: humus: grape pomace = 5:2:1:2:0, adjust the pile C / N to 25 with urea, and adjust the moisture content to 60% with ultrapure water , Inoculate 50mL mixed bacteria per kg of compost raw materials, spore suspension 2×10 6 ML -1 Among them, white rot fungi accounted for 60%, green wood enzymes accounted for 40%, aerobic composting for 60 days, turning the pile twice a week;

[...

Embodiment 3

[0062] A method for preparing humus and repairing heavy metal contaminated bottom sludge specifically includes using corn stalk compost to produce humus and leaching and repairing heavy metal bottom sludge, including the following steps:

[0063] 1. Compost design and humus extraction:

[0064] A. Use a 50L plastic box to conduct composting experiments in aerobic composting mode. Five holes are evenly drilled on the lid of the plastic box, and 40mm thick foam is attached to the surface of the box body to reduce heat loss. According to the mass ratio of composting raw materials, corn stalks: wood chips: soybean meal: humus: grape pomace = 5: 2: 1: 2:0 for aerobic composting for 60 days, using urea to adjust the pile body C / N to 20, ultra-pure water Adjust the moisture content to 60%, inoculate 50mL mixed bacteria per kg of compost raw materials, and the spore suspension 2×10 6 ML -1 Among them, white rot fungi accounted for 60%, green wood enzymes accounted for 40%, aerobic compost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com