Multifunctional polymer oil displacing agent and preparation method and application thereof

An oil-displacing agent and polymer technology are applied in the field of multifunctional polymer oil-displacing agent and its preparation, which can solve the problems of weakening oil-displacing effect, difficulty in forming oil-displacing slug, and reducing effective viscosity, and achieving good oil-displacing performance , The effect of long validity period and high profile control strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of multifunctional polymerization oil displacement agent of the present invention is:

[0038] Dissolve a certain amount of emulsifier OP-10 and hydrophobic monomer FM in deionized water, pour it into a three-necked flask, pass nitrogen to drive oxygen for 30 minutes; stir to raise the temperature, add AM, DMC, AMPS and ammonia water, and then add initiator K 2 S 2 o 8 Initiate polymerization, the reaction temperature is 50°C, and the copolymerization reaction time is 8h (without stirring), to obtain a colloidal copolymer (FPAM), which is precipitated with absolute ethanol and washed 3 times, and the precipitate is dried in a vacuum oven (80°C) , and then put it in a desiccator for later use. Table 1 is the specific formulation of the multifunctional polymer oil displacement agent of the present invention.

[0039] Table 1

[0040]

[0041] Comprehensively comparing the above experiments, the performance of the multifunctional polymer oil d...

Embodiment 2

[0042] Example 2 Viscosity-increasing performance evaluation of the multifunctional polymeric oil displacement agent of the present invention

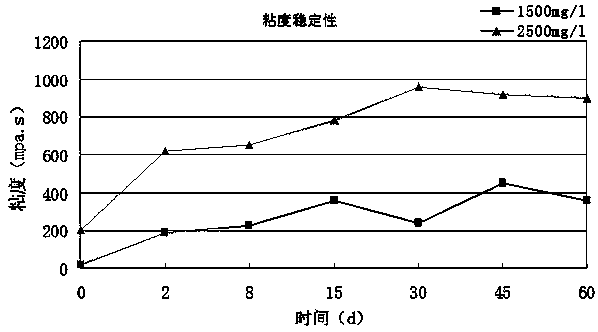

[0043] We put the multifunctional polymer oil displacing agents prepared by formula 4 with concentrations of 1500mg / l and 2500mg / l in a constant temperature water bath at 50°C, and recorded the relationship curve of the viscosity of the oil displacing agent solution with time every day. Experimental results such as figure 1 shown.

[0044] Depend on figure 1 It can be seen that when the concentration of the multifunctional polymeric oil displacement agent is 1500mg / l and 2500mg / l, the viscosity of the multifunctional polymeric oil displacement agent changes with time, and the viscosity does not change much, indicating that the oil displacement agent solution has better stability , will not degrade in the formation.

Embodiment 3

[0045] Example 3 Evaluation of the salt resistance performance of the multifunctional polymeric oil displacement agent of the present invention

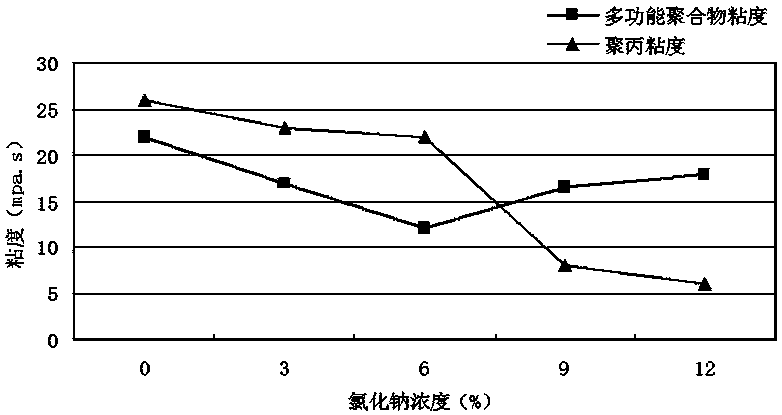

[0046] With w (NaCl) is respectively 0, 3%, 6%, 9%, 12% brine with the multifunctional polymer oil displacement agent of the present invention prepared by application formula 4 and unmodified hydrolyzed polyacrylamide (HPAM ) were prepared into aqueous solutions, and the mass fractions of multifunctional polymer oil displacement agent and hydrolyzed polyacrylamide were both 0.1%. After dissolving for 2 hours, at a temperature of 20°C and a shear rate of 1850s -1 The apparent viscosity was measured as follows, the results can be found in figure 2 .

[0047] From figure 2It can be seen that with the increase of brine content, the apparent viscosity of unmodified HPAM shows a downward trend, especially when w(NaCl) is in the range of 6% to 9%, the apparent viscosity drops rapidly. When w(NaCl) is 9% %, the apparent viscosity drops...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com