Dynamic polymer with hybrid cross-linked structure and application thereof

A hybrid cross-linking and polymer technology, applied in the field of smart polymers, can solve problems such as lack of dynamics, application limitations, hard and brittle cross-linked polymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] In the preparation process of dynamic polymer foaming materials, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam dynamic polymers.

[0086] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it gel and solidify to become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0087] Wherein, the physical foaming method is to utilize physical principles to realize the foaming of the polymer in the preparation process of the dynamic polymer, which generally includes the following four methods: (1) inert gas foaming method, that is, after adding Press the inert gas into the molten polymer or pasty mat...

Embodiment 1

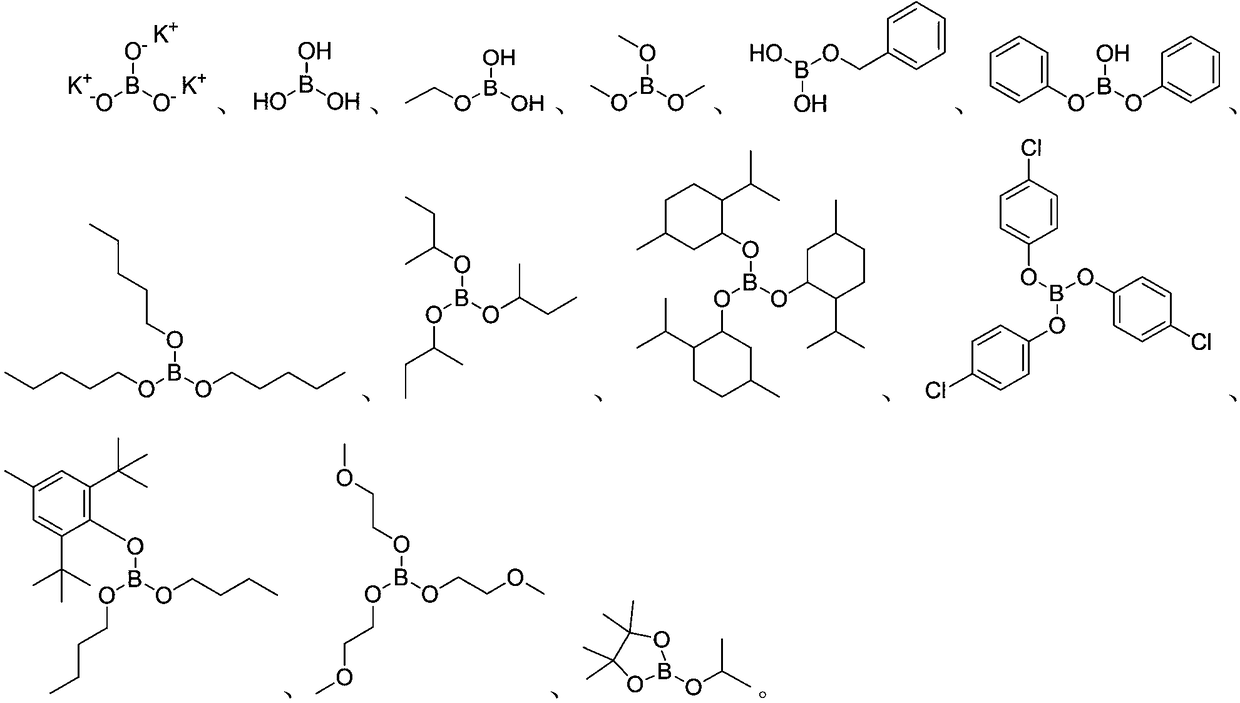

[0154] 1 molar equivalent of trimethyl borate and 10 molar equivalents of 1,4-bis(dimethylhydroxysilyl)benzene were stirred and the temperature was raised to 90°C for uniform mixing, then a small amount of triethylamine was added dropwise to continue the reaction , to obtain compound 1a.

[0155]

[0156] Dimethicone oil (average molecular weight is about 5000Da) with 15 molar equivalents of two-terminal silanol end-capped, 6 molar equivalents of tetraethoxysilane, 2 molar equivalents of compound 1a, dibutyltin dilaurate (DBTDL, for the total mass of raw materials 2%) were fully blended and cured at room temperature for 6 hours to obtain a dynamic polymer containing ordinary covalent crosslinks and inorganic borate silicon ester bonds. 100 parts by mass of the polymer and 5 parts by mass of graphene are fully blended, and the obtained composite material not only has good toughness and self-healing property, but also can be used for heat conduction, electric conduction, stre...

Embodiment 2

[0158] Add 1 molar equivalent of trimethylethoxysilane to an aqueous hydrochloric acid solution with a pH of 2.5, and stir at room temperature. After the hydrolysis is complete, add 10 molar equivalents of boric acid, and dehydrochloride after the reaction is complete to obtain compound 2a. Add 2 molar equivalents of (3-aminopropyl) dimethylethoxysilane to an aqueous hydrochloric acid solution with a pH of 2.5, and stir at room temperature. After the hydrolysis is complete, add 1 molar equivalent of compound 2a. After the reaction is complete, dehydrochloride to obtain the compound 2b.

[0159]

[0160] Weigh 5 molar equivalents of polyethylene glycol (average molecular weight is about 500Da) and 4 molar equivalents of polyethylene glycol (average molecular weight is about 500Da) terminated by carboxyl groups at both ends, and add 2-ethoxyl-1-ethoxycarbonyl-1,2-dihydroquinone Phenyl (EEDQ) was used as a condensing agent to obtain a linear dynamic covalent polymer containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com