Etching reactants and plasma-free oxide etching processes using the same

A reaction, silicon oxide technology, applied in chemical instruments and methods, cleaning methods and utensils, electrical solid devices, etc., can solve problems such as slow etching rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0271] Example 1: via NbF 5 Etched oxide layer test

[0272] by atomic layer deposition and Thick Nb 2 o 5 、 Ta 2 o 5 , ZrO 2 , HfO 2 、TiO 2 and Al 2 o 3 layer deposited on a silicon substrate. The thickness of these layers was determined using ellipsometry. Those of ordinary skill in the art will recognize that scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray photoelectron spectroscopy (XPS), secondary ionization mass spectrometry (SIMS), or Russian Electron spectroscopy (AES) was used to measure the thickness of the layer before and after etching.

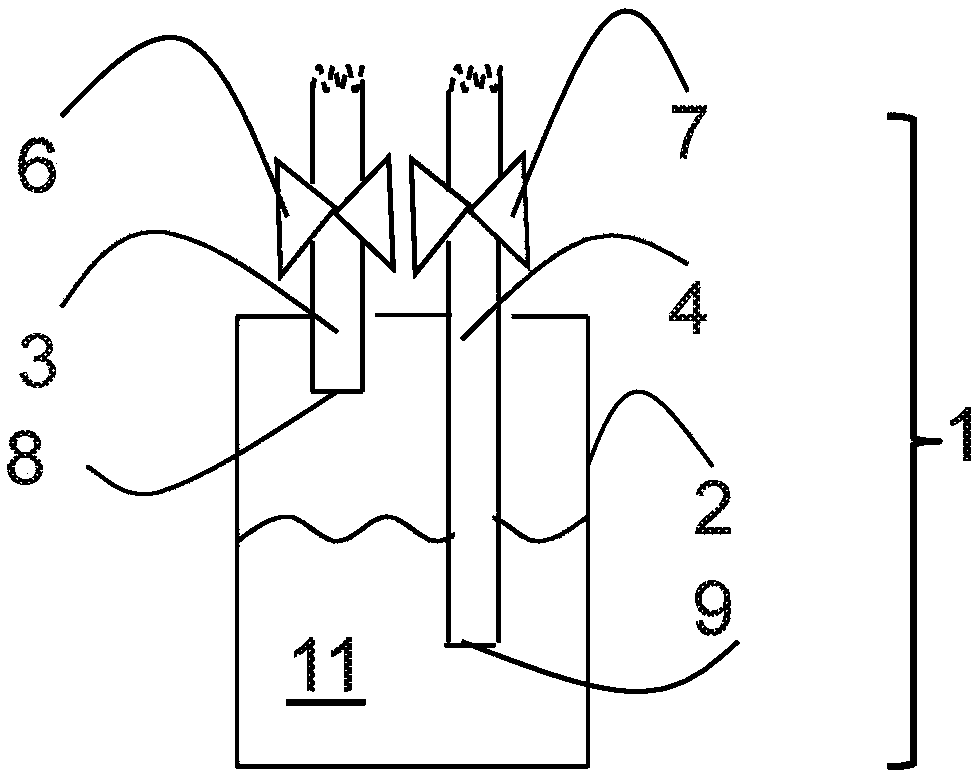

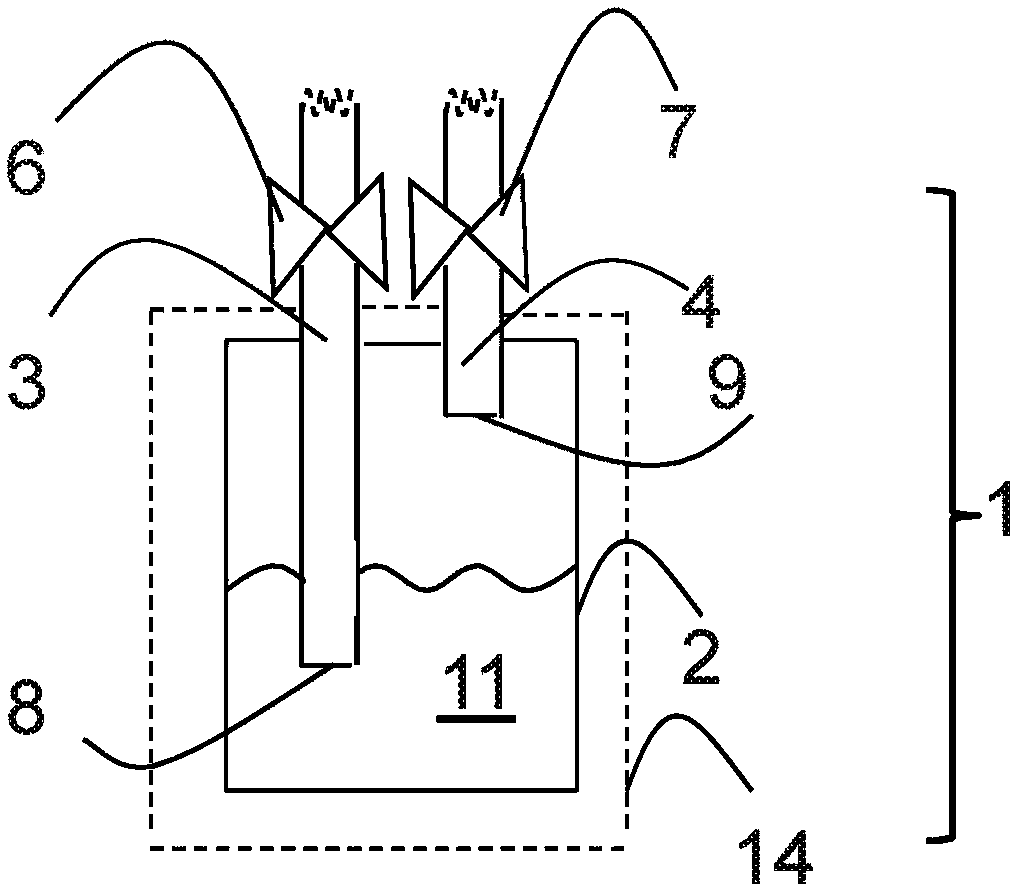

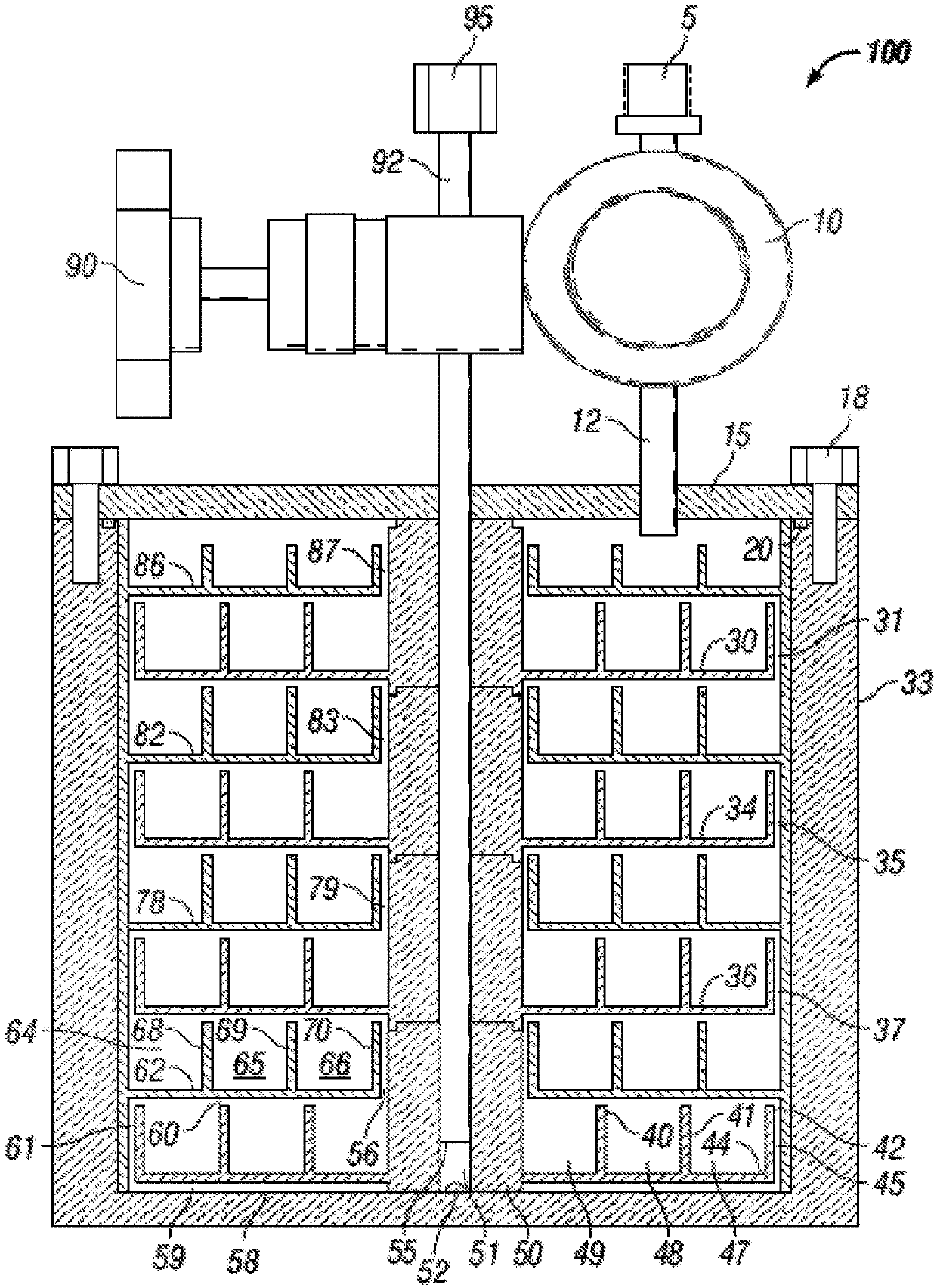

[0273] Nb via the load lock chamber 102 2 o 5 、 Ta 2 o 5 , ZrO 2 , HfO 2 、TiO 2 and Al 2 o 3 substrate and Thick SiO 2 The substrate is introduced into Figure 4 The thermal reactor 400 is placed on the wafer stage 101 heated to 200°C, 300°C, 350°C or 400°C. Reactor 400 is maintained at a pressure of 5 to 6 Torr. NbF 5 Placed in sublimator vessel 200 heated to 74°C a...

example 2

[0284] Example 2: Via NbF 5 Etched nitride layer test

[0285] Preparation of TiN TaN and SiN Floor. The substrate containing the nitride layer is introduced via the load lock chamber 102 into Figure 4 The thermal reactor 400 is placed on the wafer stage 101 heated to 350°C, 400°C or 425°C. The reactor 400 pressure was fixed at 5 to 6 Torr. NbF 5 Place in vessel 200 heated to 74°C and introduce its vapor into reactor 400 with Ar carrier gas 300 at 255 seem. The thicknesses of the TiN and TaN layers were measured using a scanning electron microscope (SEM) after 5 seconds, 10 seconds, 15 seconds, and 30 seconds. The thickness of the SiN layer was measured after 30 seconds and 90 seconds using an ellipsometer. The film thickness of any of the nitride films was unchanged and etching was not observed at any temperature. Table 2 shows that with NbF 5 Film etch rate as a function of time and temperature summary.

[0286] Table 2 by NbF 5 Summary of Nitride Etch Rat...

example 3

[0290] Example 3: via VF 5 Tests for etching oxide and nitride layers

[0291] Nb via the load lock chamber 102 2 o 5 、 Ta 2 o 5 , ZrO 2 , HfO 2 、TiO 2 、Al 2 o 3 , SiO 2 , TiN and TaN substrates introduced into Figure 4 The thermal reactor 400 is placed on the wafer stage 101 heated to 150°C, 200°C, 300°C, 350°C or 400°C.

[0292] Reactor 400 is maintained at a pressure of 5 to 6 Torr. will VF 5 Place in container 200 at room temperature. Vapor is continuously introduced into reactor 400 without any carrier gas.

[0293] Image 6 Display with VF 5 The thickness of the different oxide layers is introduced as a function of time and temperature. Introduction of total VF at 150°C 5 After 30 seconds and 90 seconds; at 200°C after 10 seconds and 30 seconds; at 300°C after 3 seconds, 5 seconds, 6 seconds, 8 seconds and 30 seconds; at 350°C for 2 seconds, 3 seconds, 5 seconds , after 10 seconds and 30 seconds; and after 1 second, 2 seconds, 3 seconds, 5 seconds, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com