Modified styrene adsorption resin, preparation method of modified styrene adsorption resin and application of modified styrene adsorption resin to refining of lignocellulose hydrolysate

A lignocellulosic and styrene-based technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve problems such as poor adsorption performance, and achieve improved hydrophilicity and high selectivity resistance, reducing the effect on microbial growth and fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

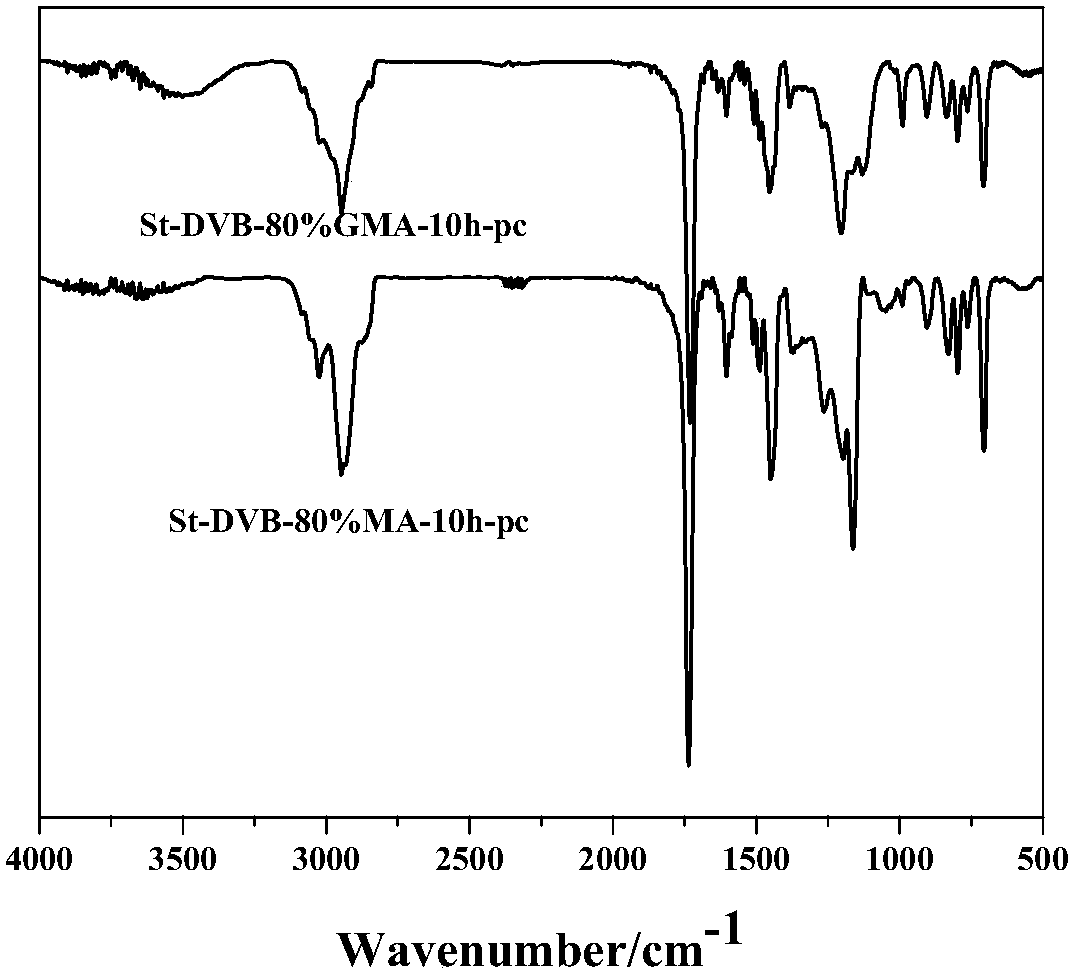

[0034] Such as Figure 1~4 Shown, the preparation of modified styrene-based adsorption resin comprises the following steps:

[0035] 1) Precursor resin synthesis

[0036] The precursor resin is synthesized by suspension polymerization, and the specific steps are as follows: 240mL of the water phase (the water phase contains 0.75% polyvinyl alcohol and 3-5 drops of 1% methylene blue solution by mass fraction) is added with a mechanical Stir, place in a 500mL three-neck flask with a thermometer and a serpentine condenser, place in an oil bath and heat to 50°C, then add the oil phase to the water phase (add 4g of styrene monomer, 20g of divinylbenzene, methacrylic acid Glycidyl ester 16g, toluene 20g, n-heptane 20g and benzoyl peroxide 0.4g), feed nitrogen 5min after, adjust stirring speed to be 160rpm, control oil droplet size. Then slowly raise the temperature to 80°C and react for 5 hours. After the reaction, the products obtained are washed alternately with hot water and de...

Embodiment 2

[0046] Same as Example 1, except that 18 g of styrene and 2 g of glycidyl methacrylate were added to obtain the modified styrene-based adsorption resin St-DVB-10% GMA-10h-pc.

[0047] The BET specific surface area of St-DVB-10%GMA-10h-pc is 544.66m 2 / g, the pore volume is 1.03cm 3 / g, the average pore diameter is 8.74nm.

Embodiment 3

[0049] Same as Example 1, except that glycidyl methacrylate was replaced by methyl acrylate to obtain modified styrene-based adsorption resin St-DVB-80%MA-10h-pc.

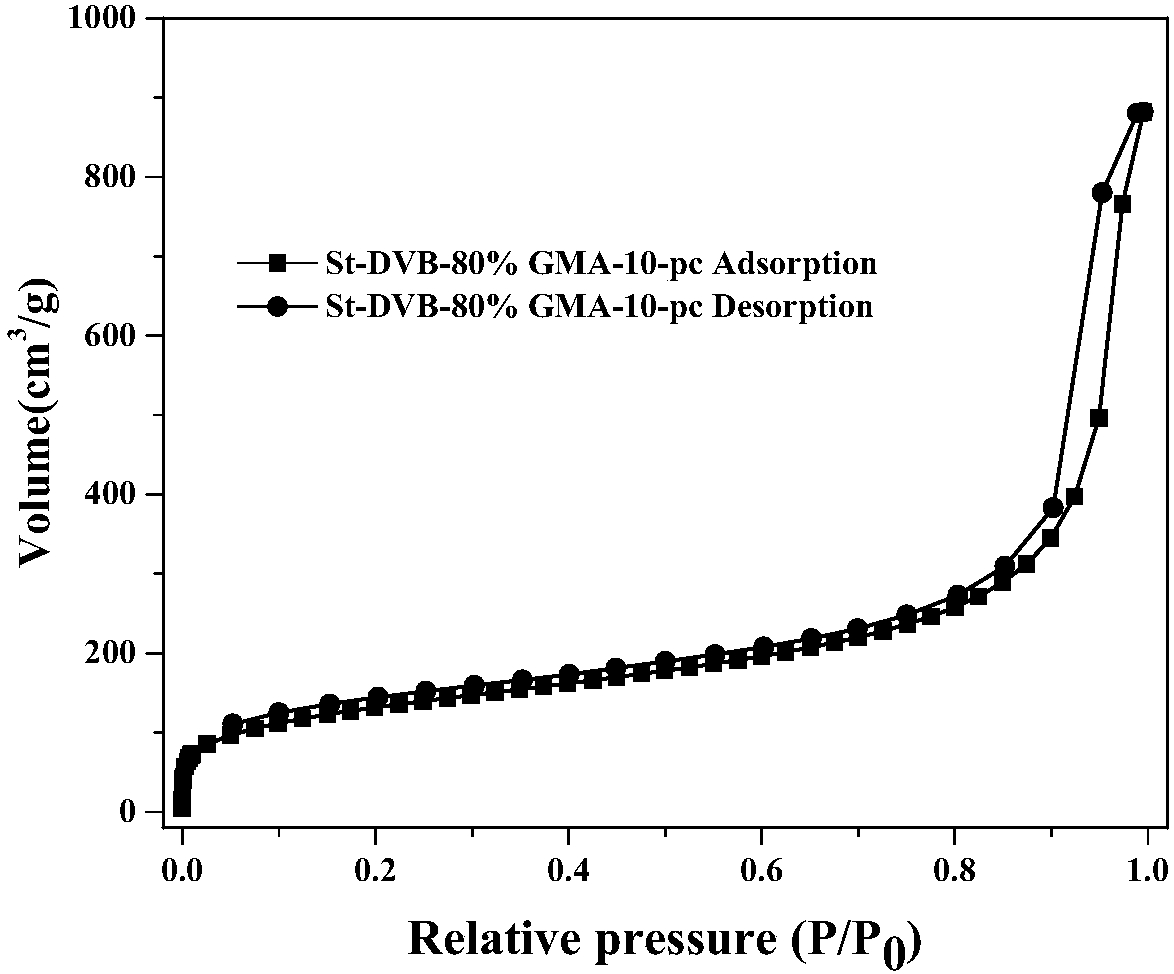

[0050] The BET specific surface area of St-DVB-80%GMA-10h-pc is 475.29m 2 / g, the pore volume is 1.36cm 3 / g, the average pore diameter is 11.48nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com