Method for preparing (6S)-5-methyltetrahydrofolate calcium

A technology of calcium methyltetrahydrofolate and folic acid, which is applied in the direction of organic chemistry, can solve the problems of affecting product purity and yield, large environmental pollution, and high production cost, and achieve the effects of complete reaction, reduced environmental pollution, and stable products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

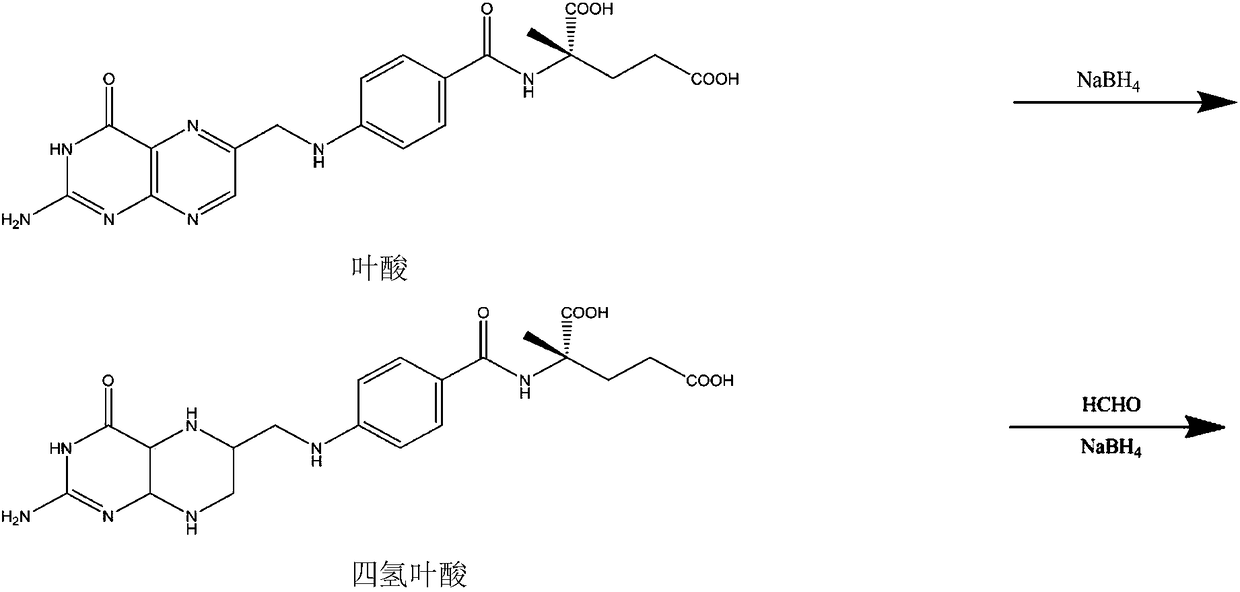

Method used

Image

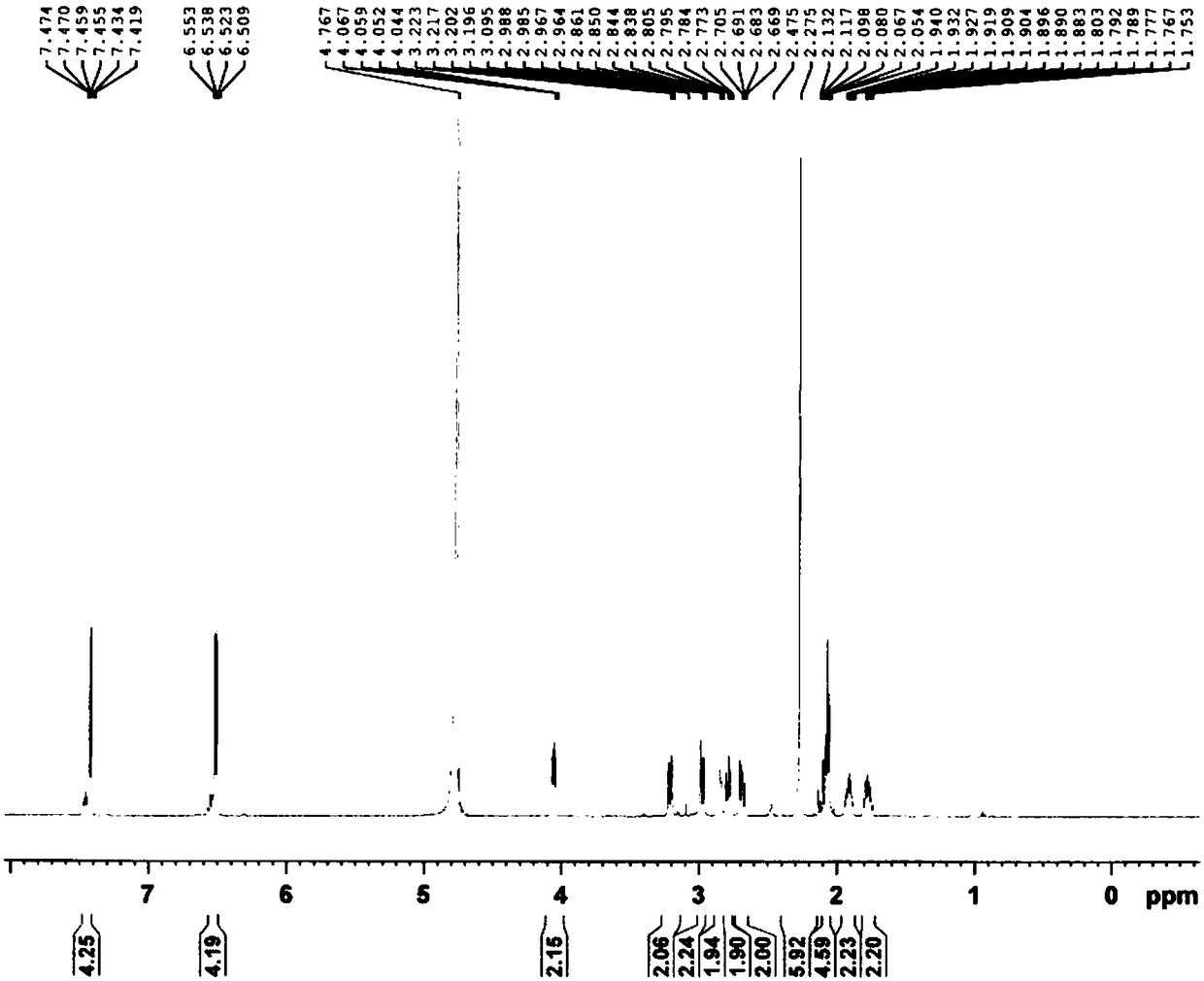

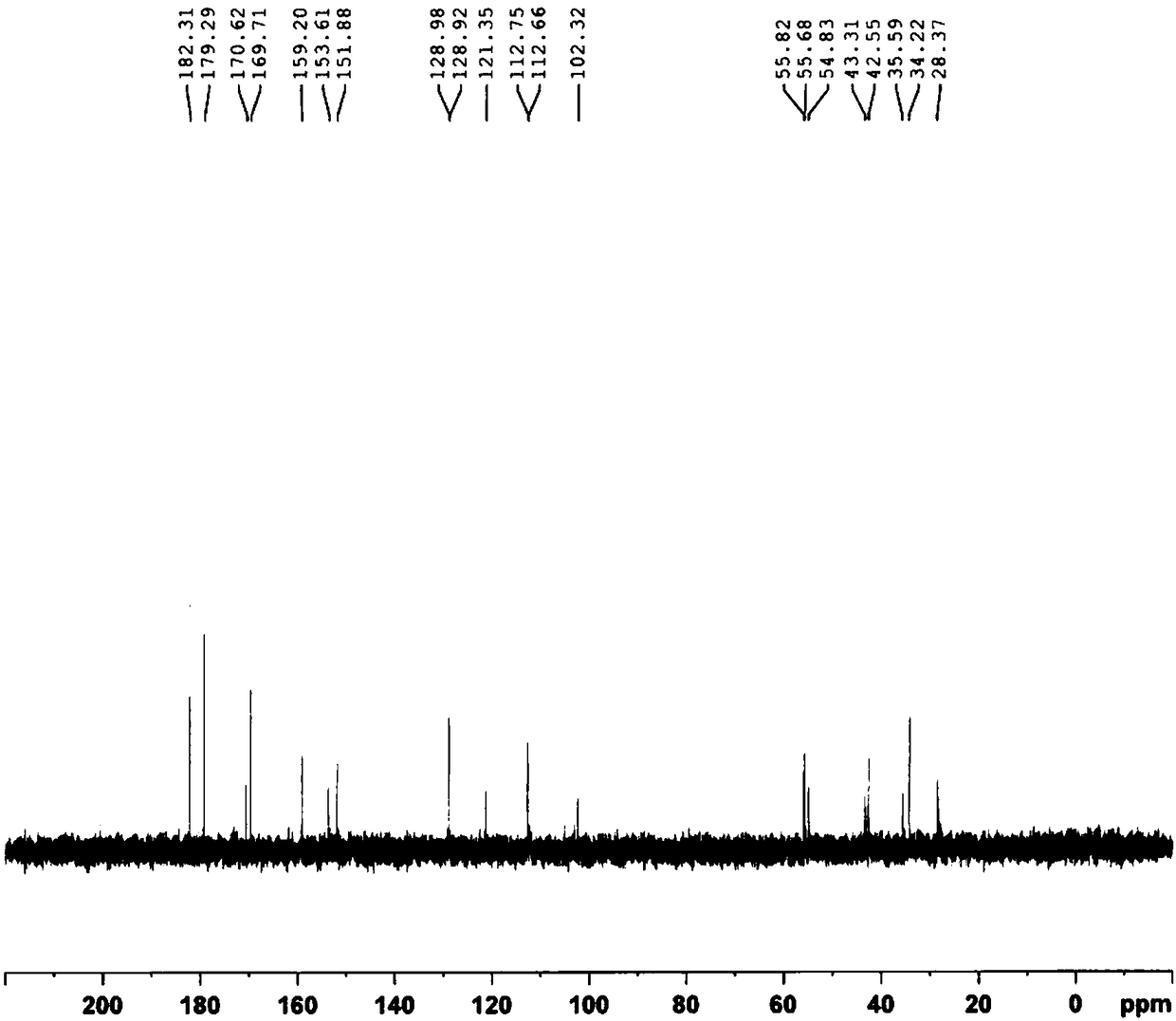

Examples

Embodiment 1

[0041] In an alkaline environment (concentration is 25% NaOH solution) drop 22.4 grams of sodium borohydride, dropwise add 128 g of a mixture of folic acid and water at a temperature of 25 ° C (the mass ratio of folic acid and water is: 1:3), After the dropwise addition, react at 85-90°C for 1 hour. After the reaction, adjust the pH to 9.0 with concentrated hydrochloric acid. After the adjustment, add 16ml of formaldehyde dropwise at 5-10°C and react at this temperature for 0.5 hours. After the reaction Add dropwise 27.2g of 40% sodium borohydride aqueous solution, keep it warm for 1 hour, heat up to 55°C and react for 0.5 hour, add 160ml of water, adjust the pH to 7.5 with concentrated hydrochloric acid, let stand at 0-10°C for 5 hours, pump Boron salts were removed by filtration, the filtrate was adjusted to pH 7.5 with hydrochloric acid, 64ml of 9% calcium chloride solution was added dropwise, stirred and crystallized at 0-10°C for 4 hours, and 5-methyltetrahydrofolate calci...

Embodiment 2

[0045] Add 22.4 grams of sodium borohydride in an alkaline environment (25% NaOH solution), add 96 ml of a mixture of folic acid and water dropwise at a temperature of 25°C (the ratio of folic acid and water is: 1:3), dropwise After the addition, react at 80-85°C for 1 hour. After the reaction, adjust the pH to 8.0 with concentrated hydrochloric acid. After the adjustment, add 16ml of formaldehyde dropwise at 5-10°C and react at this temperature for 0.5 hours. After the reaction, drop Add 27.2g of 40% sodium borohydride aqueous solution, keep it warm for 1 hour, raise the temperature to 50°C for 0.5 hour, add 160ml of water, adjust the pH to 7.5 with concentrated hydrochloric acid, let stand at 0-10°C for 8 hours, and filter with suction Boron salts were removed, the filtrate was adjusted to pH 7.5 with hydrochloric acid, 110ml of 5% calcium chloride solution was added dropwise, stirred and crystallized at 0-10°C for 8 hours, and the wet powder of calcium 5-methyltetrahydrofola...

Embodiment 3

[0049] Add 22.4 grams of sodium borohydride in an alkaline environment (25% NaOH solution), add 96 ml of a mixture of folic acid and water dropwise at a temperature of 25°C (the ratio of folic acid and water is: 1:3), dropwise After the addition, react at 95-100°C for 1 hour. After the reaction, adjust the pH to 10.0 with concentrated hydrochloric acid. After the adjustment, add 16ml of formaldehyde dropwise at 5-10°C and react at this temperature for 0.5 hours. After the reaction, drop Add 27.2g of 40% sodium borohydride aqueous solution, keep it warm for 1 hour, raise the temperature to 60°C for 0.5 hour, add 160ml of water, adjust the pH to 7.5 with concentrated hydrochloric acid, let stand at 0-10°C for 12 hours, and filter with suction Boron salts were removed, the filtrate was adjusted to pH 7.5 with hydrochloric acid, 40ml of 15% calcium chloride solution was added dropwise, stirred and crystallized at 0-10°C for 6 hours, and 5-methyltetrahydrofolate calcium wet powder w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com