Method for preparing xylooligosaccharide through H2O2-HOAc coupling pre-processing

A technology of xylo-oligosaccharide and h2o2-hoac, applied in the direction of fermentation, can solve the problems of hindering the enzymatic hydrolysis of xylan, low extraction rate of pretreatment method, affecting the yield of xylo-oligosaccharide, etc. Environmental pollution, lower raw material pretreatment temperature, easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

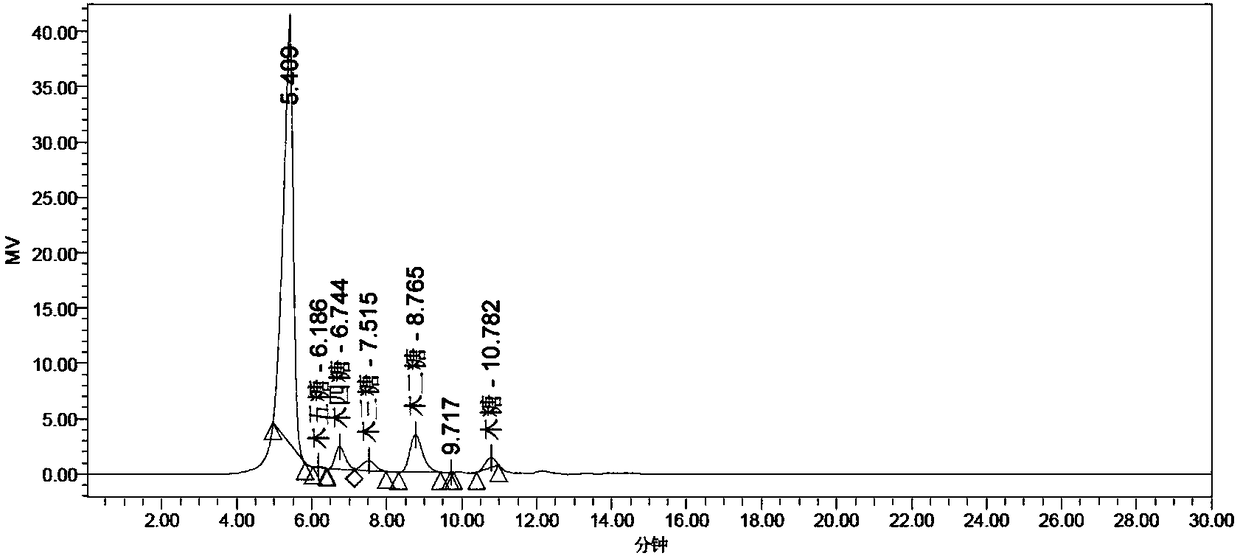

Embodiment 1

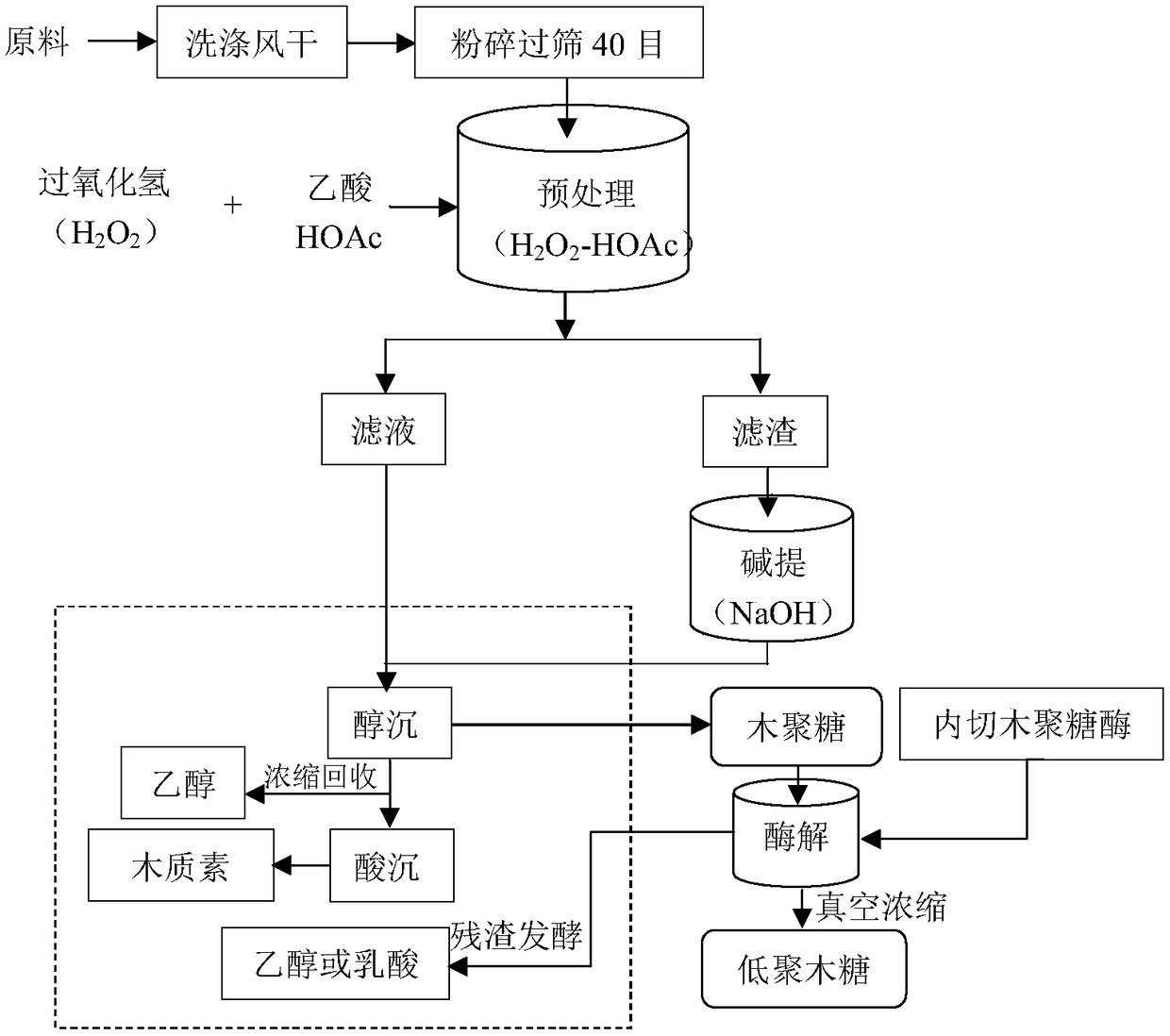

[0037] Example 1 A kind of H 2 O 2 Method for preparing xylo-oligosaccharide by -HOAc coupling pretreatment

[0038] This embodiment provides a H 2 O 2 -The method for preparing xylo-oligosaccharides with HOAc coupling pretreatment, including:

[0039] (1) Take 5g (absolutely dry) pulverized and sieved bagasse of 40 meshes, placed in a 200mL polytetrafluoroethylene reaction tank, followed by H 2 O 2 (21.6 mol / L): HOAc (8.74 mol / L)=1:1 to adjust the solid-liquid ratio to 1:20.

[0040] After the polytetrafluoroethylene reaction tank was sealed, it was placed in a homogeneous reaction kettle, and the pretreatment temperature was heated to the required reaction temperature of 60°C at a speed of 5°C / min, and the reaction was carried out at a turnover speed of 10rpm for 3h.

[0041] After the pretreatment, the solid residue was washed to neutrality and dried at 50°C to directly enter the stage of alkaline extraction of xylan.

[0042] (2) Take 3 g of drying raw materials and...

Embodiment 2

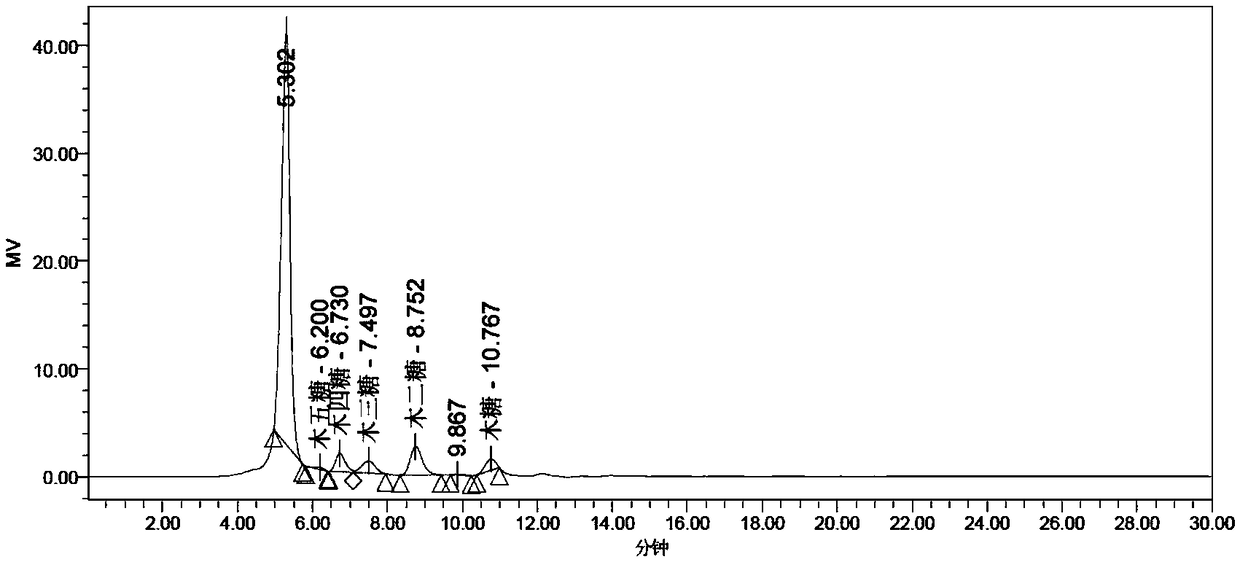

[0045] Example 2 A kind of H 2 O 2Method for preparing xylo-oligosaccharide by -HOAc coupling pretreatment

[0046] This embodiment provides a H 2 O 2 -The method for preparing xylo-oligosaccharides with HOAc coupling pretreatment, including:

[0047] (1) Take 5g (absolutely dry) pulverized and sieved bagasse of 40 meshes, placed in a 200mL polytetrafluoroethylene reaction tank, followed by H 2 O 2 (21.6 mol / L): HOAc (8.74 mol / L)=1:1 to adjust the solid-liquid ratio to 1:20.

[0048] After the polytetrafluoroethylene reaction tank was sealed, it was placed in a homogeneous reaction kettle, and the pretreatment temperature was heated to the required reaction temperature of 80°C at a speed of 5°C / min, and the reaction was carried out at a turnover speed of 10rpm for 3h.

[0049] After the pretreatment, the solid residue was washed to neutrality and dried at 50°C to directly enter the stage of alkaline extraction of xylan.

[0050] (2) Take 3 g of drying raw materials and ...

Embodiment 3

[0054] Example 3 A kind of H 2 O 2 Method for preparing xylo-oligosaccharide by -HOAc coupling pretreatment

[0055] This embodiment provides a H 2 O 2 -The method for preparing xylo-oligosaccharides with HOAc coupling pretreatment, including:

[0056] (1) Take 5g (absolutely dry) pulverized and sieved bagasse of 40 meshes, placed in a 200mL polytetrafluoroethylene reaction tank, followed by H 2 O 2 (21.6 mol / L): HOAc (8.74 mol / L)=1:1 to adjust the solid-liquid ratio to 1:20.

[0057] After sealing the polytetrafluoroethylene reaction tank, put it in a homogeneous reaction kettle, heat the pretreatment temperature to the desired reaction temperature of 100°C at a speed of 5°C / min, and react at a turnover speed of 10rpm for 3h.

[0058] After the pretreatment, the solid residue was washed to neutrality and dried at 50°C to directly enter the stage of alkaline extraction of xylan.

[0059] (2) Take 3 g of drying raw materials and put it in a 500 mL glass beaker. The dosag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com