Method for improving lignocellulose enzymolysis and saccharification efficiency

A technology of lignocellulosic enzymes and lignocellulose, which is applied in the field of pretreatment to improve the efficiency of lignocellulose enzymatic hydrolysis and saccharification, can solve the problems of high cost and increase of fermentation inhibitors, and achieve the effect of low energy consumption and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Pulverize rice stalks with a water content of 8% with a small pulverizer to make the particle size less than 2mm, take 108.7g of the material and put it into a 1L glass bottle with a sealed cover, add 375.9mL of distilled water, 550mL of absolute ethanol and 10.8 Put mL 98% sulfuric acid into a vertical pressure steam sterilizer and heat to 120°C for pretreatment reaction. The reaction time is 60 minutes to obtain the mixture;

[0025] (2) Neutralize the obtained pretreated solid-liquid mixture with 1M NaOH aqueous solution to neutrality, then filter it with 8 layers of gauze, and suspend the liquid at 45°C to obtain recovered ethanol, and the liquid left in the distiller is rich Solutions containing five-carbon sugars;

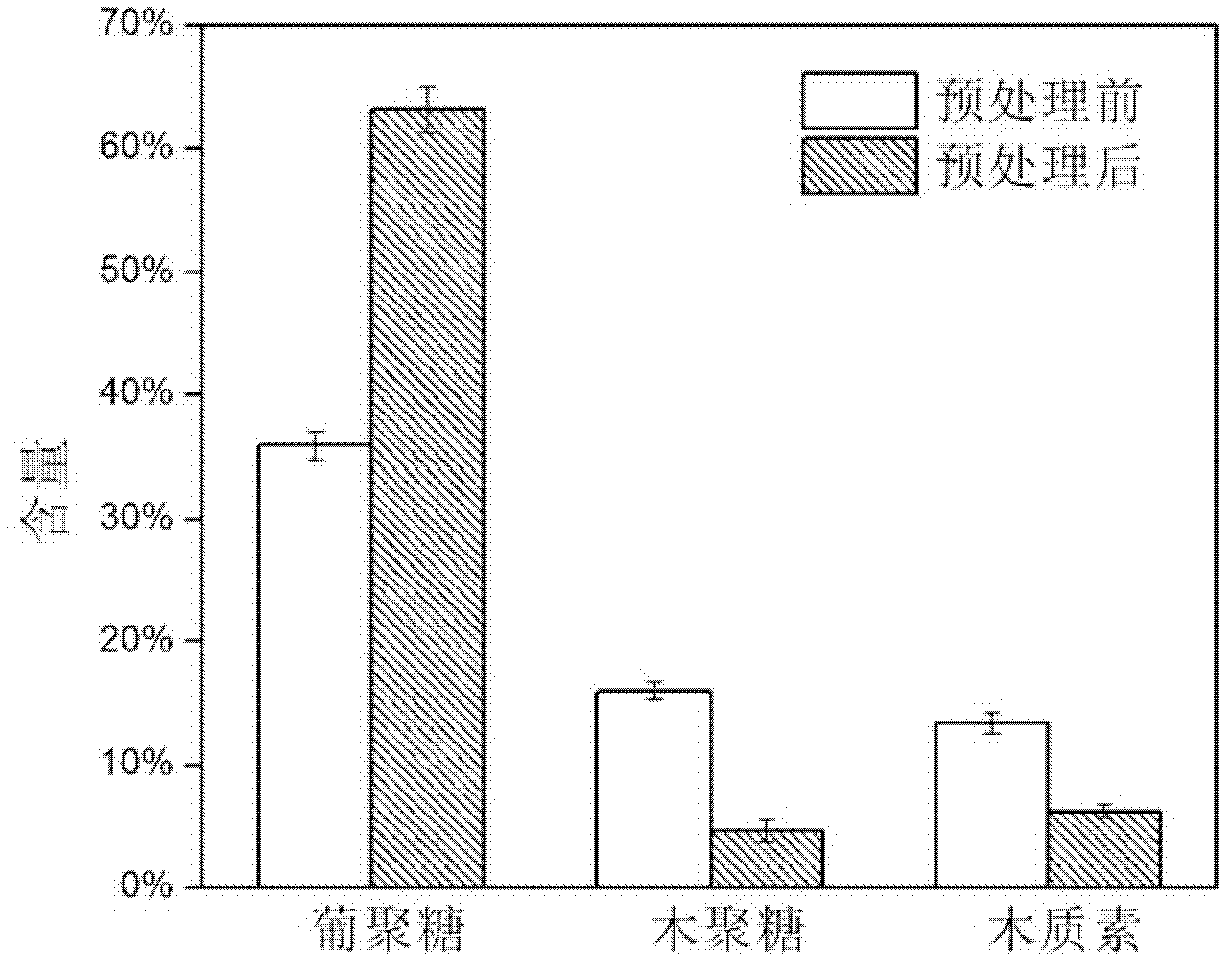

[0026] (3) drying the solid at 45°C, figure 1 Rice straw (lignocellulosic material, figure 1 The comparison between the content of the main components in the solids marked as before pretreatment) and after pretreatment shows that the content of g...

Embodiment 2

[0029] (1) Grind corn stalks with a water content of 7% with a small pulverizer to make the particle size less than 1mm, take 10.7g of the material and put it into a 150mL stainless steel reaction tube, add 38.3mL of distilled water, 55mL of absolute ethanol and 0.54mL of 98% Sulfuric acid was put into an oil bath for reaction at a temperature of 150°C and a reaction time of 30 minutes to obtain a mixture;

[0030] (2) Neutralize the obtained solid-liquid mixture to neutrality with 1M NaOH, then filter it with 8 layers of gauze, and suspend the liquid at 45°C to obtain recovered ethanol and a solution rich in five-carbon sugar;

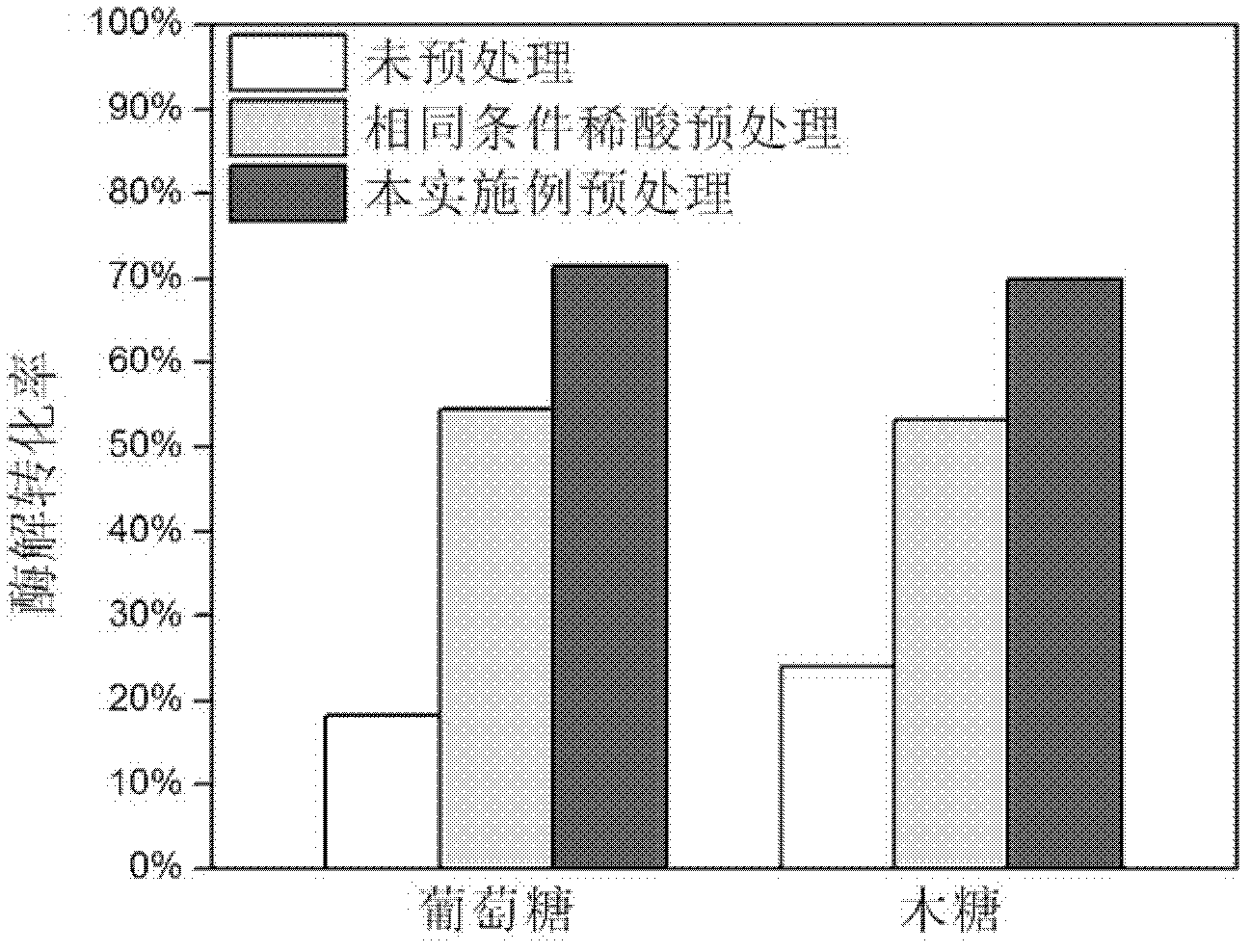

[0031] (3) After drying the solid at 45°C, take 20g of the dried solid and put it into a 500mL Erlenmeyer flask, and add 10.7mL of cellulase Spezyme CP (Genecor, the enzyme activity is 35FPU / mL) and 160mL of water, and add 1M citric acid Sodium buffer solution made pH = 4.8, reacted at 50°C, 250rpm shaker for 72h, centrifuged the solid-liquid mixture ...

Embodiment 3

[0033] (1) shearing the wheat straw to make the particle diameter less than 1cm, adding ethanol, sulfuric acid and water to mix, so that the mass concentration of wheat straw in the mixture is 20%, the mass concentration of ethanol is 80%, and the mass concentration of sulfuric acid is 2%. Heat to 160°C in a high-temperature and high-pressure-resistant closed reactor for pretreatment, and the reaction time is 30 minutes to obtain a mixture;

[0034] (2) The obtained solid-liquid mixture is neutralized with 1M NaOH aqueous solution, filtered with a filter cloth, the solid-liquid is separated, and the liquid is distilled. The steamed component is recyclable ethanol, and the liquid left in the distiller is rich Solutions containing five-carbon sugars;

[0035] (3) After the solid is dried, add cellulase and water, wherein the mass ratio of solid to water is 1: 29.5, the ratio of solid to cellulase is 1g: 4.5FPU, adjust the pH with 1M sodium citrate buffer Adjusted to 4.6, enzymo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com