Graphene-modified starch multifunctional composite material and preparation method thereof

A technology of graphene modification and composite materials, which is applied in the field of starch material modification, can solve the problems of reducing costs and increasing the amount of addition, and achieves the goals of improving barrier properties, increasing thermal decomposition temperature, and increasing disintegration rate and disintegration speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

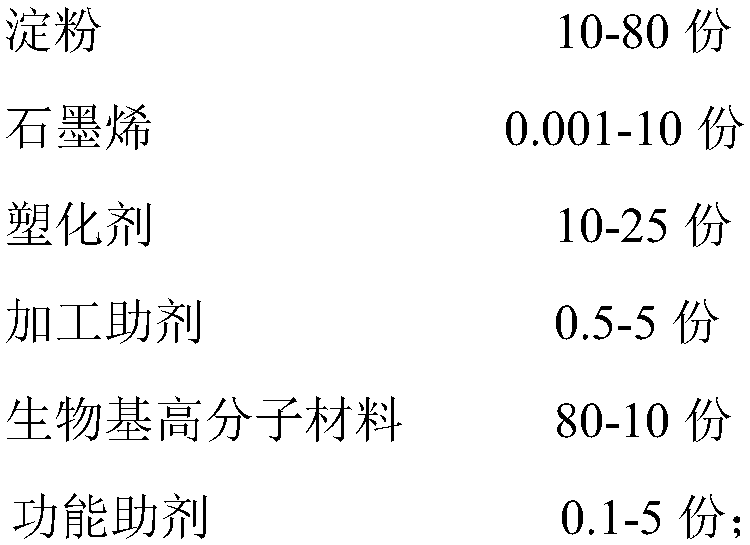

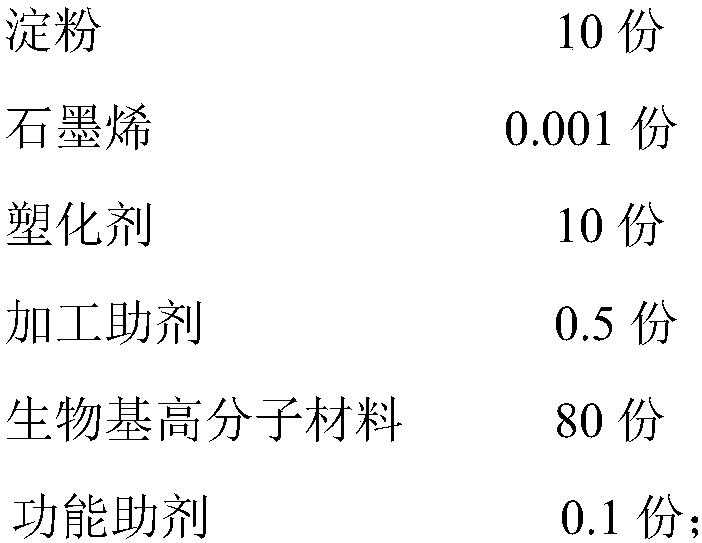

[0029] Described graphene modified starch multifunctional composite material is made of the following raw materials in parts by weight:

[0030]

[0031] The plasticizer is a mixture of purified water, sodium alginate, ethylene diformamide, glycerol and o-p-toluenesulfonamide, and the mixing mass ratio is 3:1:3:2:6.

[0032] The starch is corn starch, the particle size of the starch is 80 mesh, and the moisture content of the starch is 13%.

[0033] The graphene is a powder with a 3-layer benzene ring structure and a sheet diameter of 1000 nm.

[0034] The processing aid is a mixture of antioxidant, lubricant, surfactant and antibacterial agent, and the mixing mass ratio is 1:3:4:6. Antioxidant is 1010; lubricant is calcium stearate; surfactant is polyoxyethylene ether; antibacterial agent is nano silver ion.

[0035] The bio-based polymer material is PVA. The degree of polymerization of PVA is 300, the degree of alcoholysis is 80%, and the particle size of PVA powder is...

Embodiment 2

[0040] Described graphene modified starch multifunctional composite material is made of the following raw materials in parts by weight:

[0041]

[0042] Described plasticizer is the mixture of ethylene diformamide, glycerol, maltitol, chitosan, chitin and glyceryl monostearate, and the mixing mass ratio is 4:1:3:1:2: 2.

[0043] The starch is potato starch and tapioca starch, the mixing mass ratio is 3:2, the particle size of the starch is 85 mesh, and the moisture content of the starch is 11%.

[0044] The graphene is an oil agent with a 10-layer benzene ring structure and a sheet diameter of 900 nm.

[0045] The processing aid is a mixture of antioxidant, lubricant, surfactant and antibacterial agent, and the mixing mass ratio is 1:1:1:1. The antioxidant is 168; the lubricant is nano silicon dioxide; the surfactant is potassium laurate; the antibacterial agent is medical stone.

[0046] The bio-based polymer material is PVA. The degree of polymerization of PVA is 300...

Embodiment 3

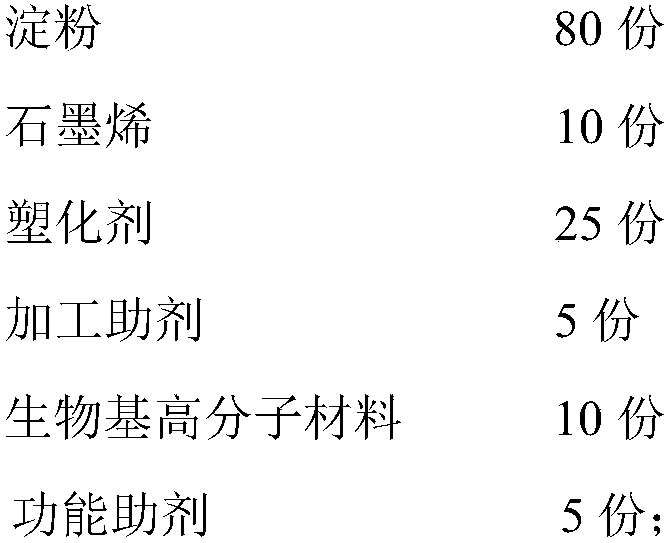

[0051] Described graphene modified starch multifunctional composite material is made of the following raw materials in parts by weight:

[0052]

[0053] The plasticizer is a mixture of chitosan, chitin, citric acid ester and glyceryl monostearate, and the mixing mass ratio is 2:4:3:6.

[0054] The starch is sweet potato starch, the particle size of the starch is 85 mesh, and the moisture content of the starch is 10%.

[0055] The graphene is an aqueous liquid having a 5-layer benzene ring structure and a sheet diameter of 850 nm.

[0056] The processing aid is a mixture of antioxidant, lubricant, surfactant and antibacterial agent, and the mixing mass ratio is 1:3:2:1. The antioxidant is 300; the lubricant is oleic acid amide; the surfactant is a silane coupling agent; the antibacterial agent is a mixture of nano-silver ions, nano-titanium ions and medical stone, and the mixing mass ratio is 1:2:1.

[0057] The bio-based polymer material is PVA. The degree of polymeriza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com