Preparation method of environmental-friendly breathable composite film

A composite film and environment-friendly technology, applied in the field of preparation of environment-friendly breathable composite films, can solve the problems of inability to eliminate visual pollution, consume a large amount of food, etc., and achieve the effects of sustainable development, good mechanical properties, and good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

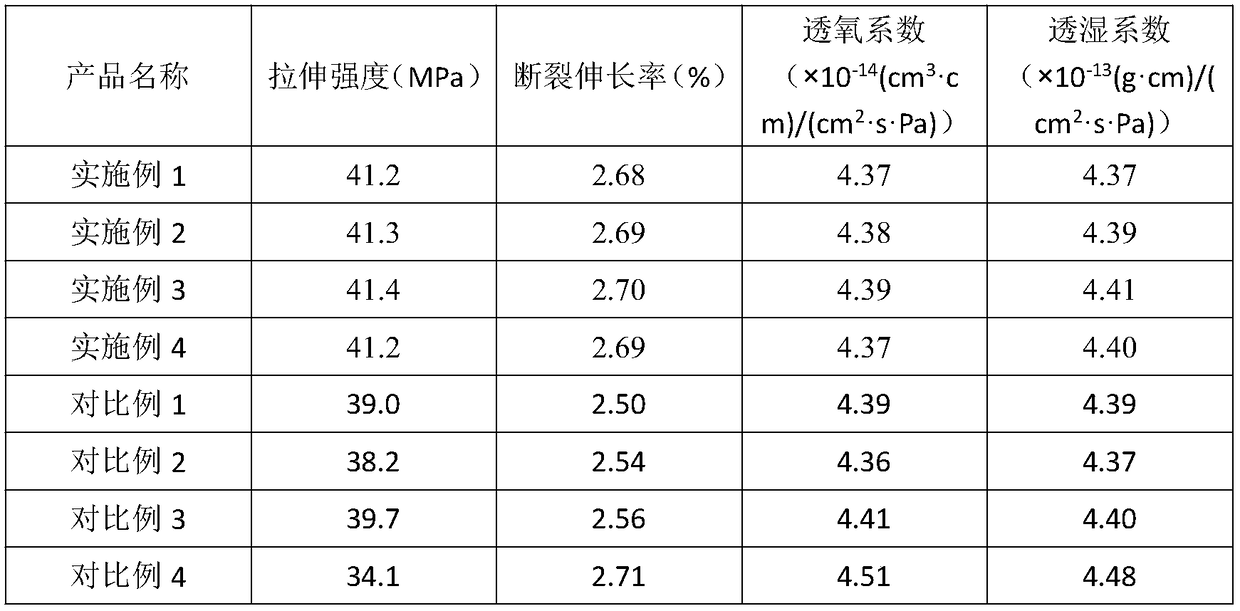

Examples

Embodiment 1

[0028] A preparation method of an environment-friendly breathable composite film, the components are calculated by weight, comprising the following steps:

[0029] (1) Take 30 parts of hardwood kraft dry pulp board and pre-soak for 24 hours, use a fiber dissociation machine to disintegrate into a fiber slurry suspension with a pulp concentration of 1%, add 5 parts of bamboo pulp, and then add 5 parts of 2,2, 6,6-Tetramethylpiperidine oxide, 10 parts of sodium bromide and sodium hypochlorite solution were monitored with a pH meter and NaOH solution was continuously added dropwise to maintain the pH of the reaction system at 10.5 until the pH value of the reaction system no longer changed;

[0030] (2) adding ethanol, stirring at room temperature to terminate the reaction;

[0031] (3) The slurry is repeatedly washed with deionized water until the conductivity of the filtrate is 9 μS / cm;

[0032] (4) Transfer to a grinder for grinding, the grinding scale is -5 μm, the rotation ...

Embodiment 2

[0038] A preparation method of an environment-friendly breathable composite film, the components are calculated by weight, comprising the following steps:

[0039] (1) Take 35 parts of hardwood kraft dry pulp boards and pre-soak them for 24 hours, use a fiber dissociation machine to decompose into a fiber slurry suspension with a pulp concentration of 1%, add 6 parts of bamboo pulp, and then add 6 parts of 2,2, 6,6-Tetramethylpiperidine oxide, 13 parts of sodium bromide and sodium hypochlorite solution were monitored with a pH meter and NaOH solution was continuously added dropwise to maintain the pH of the reaction system at 10.5 until the pH value of the reaction system no longer changed;

[0040] (2) adding ethanol, stirring at room temperature to terminate the reaction;

[0041] (3) Wash the slurry repeatedly with deionized water until the conductivity of the filtrate is 8.5 μS / cm;

[0042] (4) Transfer to a grinder for grinding, the grinding scale is -5 μm, the rotation ...

Embodiment 3

[0048] A preparation method of an environment-friendly breathable composite film, the components are calculated by weight, comprising the following steps:

[0049] (1) Take 35 parts of hardwood kraft pulp dry pulp board and pre-soak for 24 hours, use a fiber dissociation machine to disintegrate into a fiber slurry suspension with a pulp concentration of 1%, add 8 parts of bamboo pulp, and then add 7 parts of 2,2, 6,6-Tetramethylpiperidine oxide, 15 parts of sodium bromide and sodium hypochlorite solution were monitored with a pH meter and NaOH solution was continuously added dropwise to maintain the pH of the reaction system at 10.5 until the pH value of the reaction system no longer changed;

[0050] (2) adding ethanol, stirring at room temperature to terminate the reaction;

[0051] (3) Wash the slurry repeatedly with deionized water until the conductivity of the filtrate is 8 μS / cm;

[0052] (4) Transfer to a grinder for grinding, the grinding scale is -5 μm, the rotation sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com