A kind of environment-friendly fireproof coating and preparation method thereof

A fire-resistant coating and environmental protection technology, applied in fire-resistant coatings, polyester coatings, coatings, etc., can solve the problems of high toxicity of fire-resistant coatings, low soil burial degradation rate, easy cracking, etc., to reduce pulverization and soil burial degradation High efficiency, high temperature is not easy to crack and pulverize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

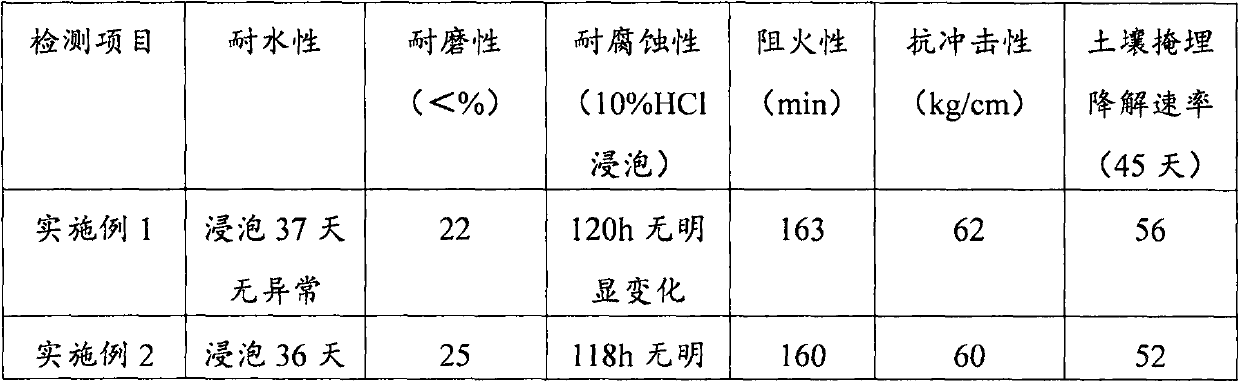

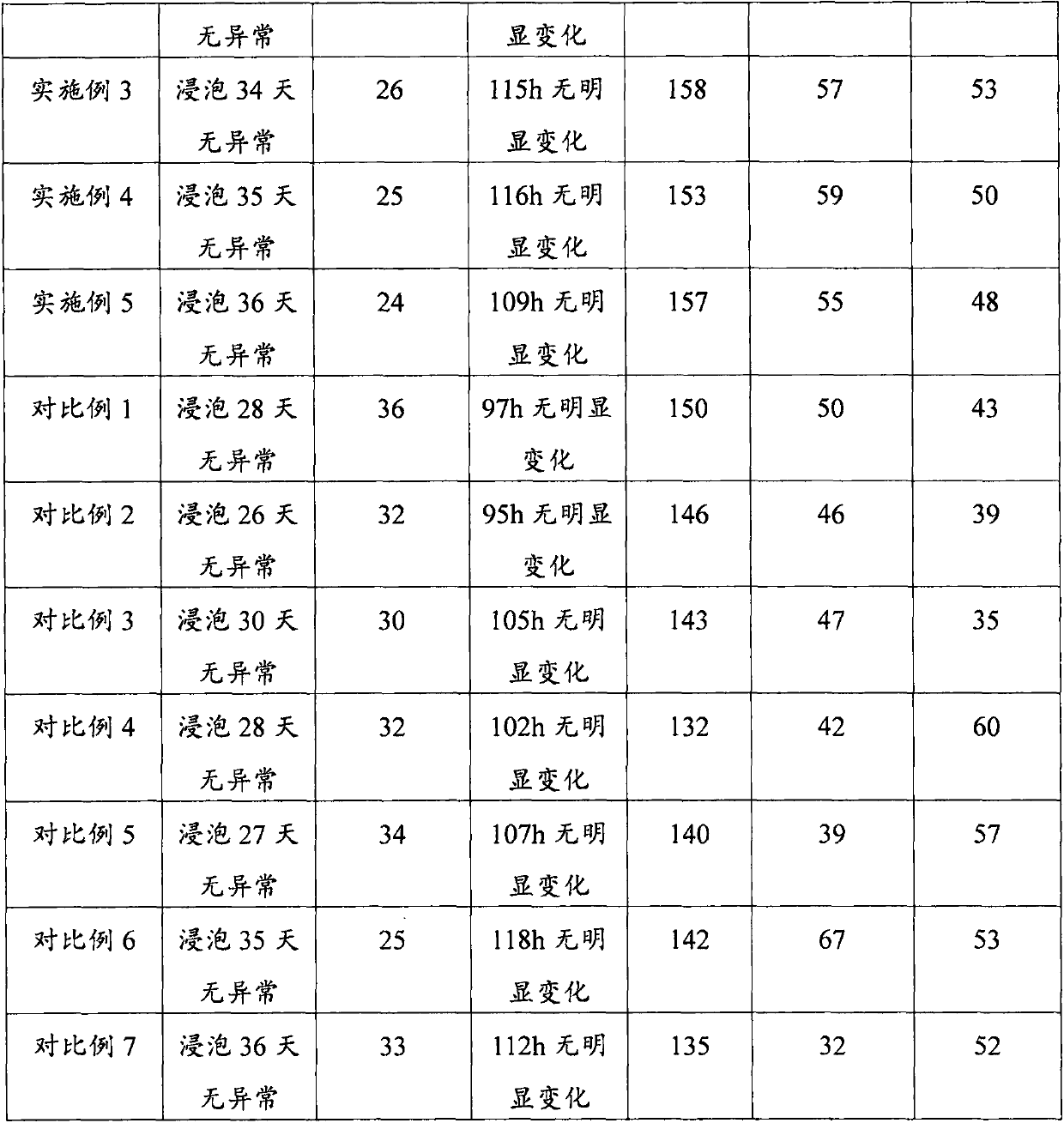

Examples

Embodiment 1

[0034] An environmentally friendly fireproof coating, comprising the following raw materials in parts by weight: 200 parts of polylactic acid compound, 24 parts of glass fiber, 26 parts of expanded perlite, 17 parts of ammonium polyphosphate, 14 parts of nano-titanium dioxide, 10 parts of anti-cracking agent lignocellulose 9 parts of 3-(methacryloyloxy)propyltrimethoxysilane, 12 parts of tricresyl phosphate, and 5 parts of modified bentonite.

[0035] The polylactic acid compound comprises the following components by weight: 120 parts of high molecular weight polylactic acid, 45 parts of low molecular weight polylactic acid, 32 parts of cornstarch, 20 parts of nano silicon dioxide, 13 parts of dibutyltin dilaurate, 5 parts of epoxy soybean oil share. The number-average molecular weight of the high-molecular-weight polylactic acid is 80,000-100,000 daltons, and the number-average molecular weight of the low-molecular-weight polylactic acid is 12,000-18,000 daltons; the modified...

Embodiment 2

[0041] An environmentally friendly fireproof coating, comprising the following raw materials in parts by weight: 175 parts of polylactic acid compound, 30 parts of glass fiber, 18 parts of expanded perlite, 16 parts of ammonium polyphosphate, 11 parts of nano-titanium dioxide, and 9 parts of anti-cracking agent polypropylene fiber 13 parts of 3-(methacryloyloxy)propyltrimethoxysilane, 10 parts of tricresyl phosphate, and 5 parts of modified bentonite.

[0042] The polylactic acid compound comprises the following components by weight: 108 parts of high molecular weight polylactic acid, 35 parts of low molecular weight polylactic acid, 27 parts of cornstarch, 22 parts of nano silicon dioxide, 15 parts of dibutyltin dilaurate, 4 parts of epoxy soybean oil share. The number-average molecular weight of the high-molecular-weight polylactic acid is 80,000-100,000 daltons, and the number-average molecular weight of the low-molecular-weight polylactic acid is 12,000-18,000 daltons; the...

Embodiment 3

[0045] An environmentally friendly fireproof coating, comprising the following raw materials in parts by weight: 210 parts of polylactic acid compound, 30 parts of glass fiber, 26 parts of expanded perlite, 18 parts of ammonium polyphosphate, 12 parts of nano-titanium dioxide, and 15 parts of anti-crack agent polypropylene fiber 12 parts of 3-(methacryloyloxy)propyltrimethoxysilane, 11 parts of tricresyl phosphate, and 7 parts of modified bentonite.

[0046] The polylactic acid compound comprises the following components by weight: 132 parts of high molecular weight polylactic acid, 50 parts of low molecular weight polylactic acid, 35 parts of cornstarch, 23 parts of nano silicon dioxide, 16 parts of dibutyltin dilaurate, 8 parts of epoxy soybean oil share. The number-average molecular weight of the high-molecular-weight polylactic acid is 80,000-100,000 daltons, and the number-average molecular weight of the low-molecular-weight polylactic acid is 12,000-18,000 daltons; the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com