A method for degrading lignin in papermaking black liquor

A technology for papermaking black liquor and lignin, which is applied in the field of lignin resource utilization, can solve the problems of no specific solution for the separation of aromatic products, difficulty in industrially large-scale processing of papermaking black liquor, harsh degradation conditions, etc. Conducive to large-scale industrial processing, improving utilization efficiency and service life, and good reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 (extraction of lignin in papermaking black liquor)

[0031] (Example 1.1) Papermaking black liquor 1L, add concentrated hydrochloric acid while stirring to adjust the pH to 2, stir at 70°C for 4h, centrifuge to take the lower layer slurry, add alkali to adjust the pH to 13, stir for 2h, filter, add hydrochloric acid to the filtrate to adjust the pH to 2. Stir for 2 hours, filter, wash the solid with water until neutral, and dry at 105°C to obtain lignin.

[0032] (Example 1.2) 1L of papermaking black liquor, add concentrated hydrochloric acid while stirring to adjust the pH to 1, stir at 60°C for 4h, centrifuge to take the lower layer of slurry, add alkali to adjust the pH to 12, stir for 2h, filter, add hydrochloric acid to the filtrate to adjust the pH to 3. Stir for 2 hours, filter, wash the solid with water until neutral, and dry at 105°C to obtain lignin.

[0033] (Example 1.3) 1L of papermaking black liquor, add concentrated hydrochloric acid while s...

Embodiment 2

[0034] Embodiment 2 (catalyst preparation)

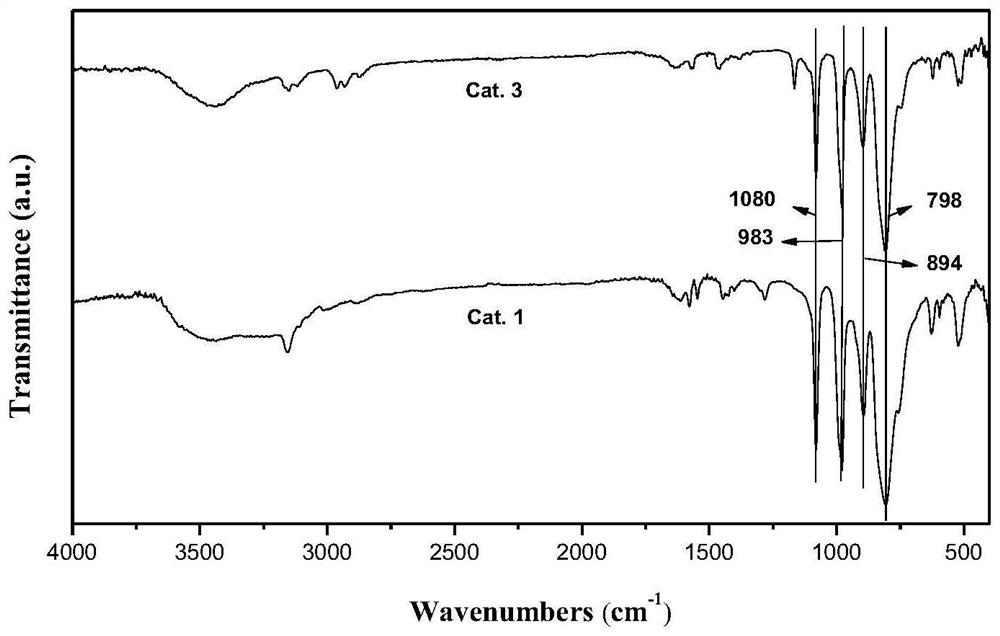

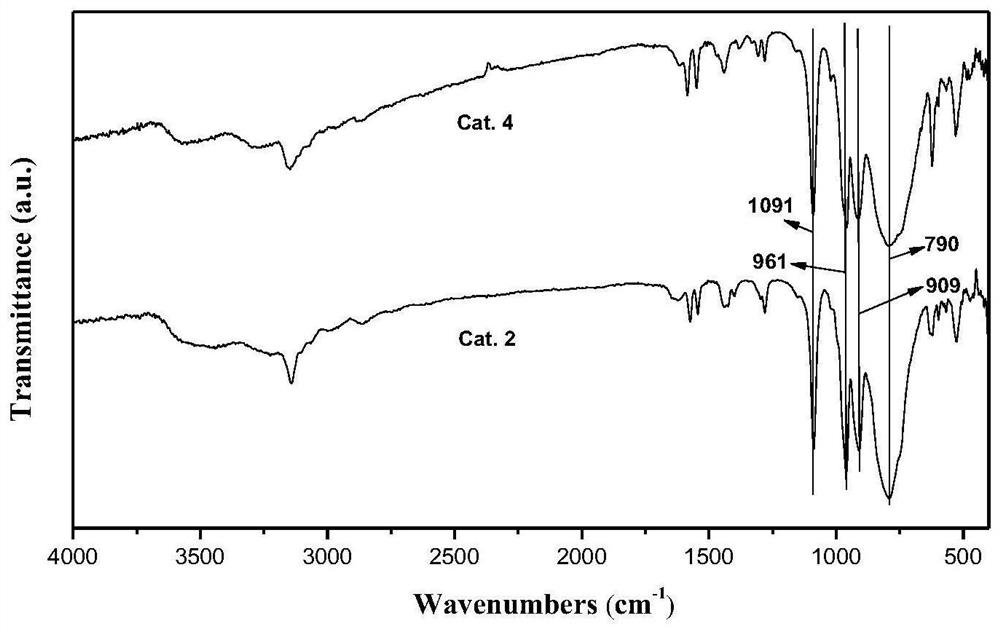

[0035] 9gNa 2 WO 4 2H 2 Dissolve O in 8mL water, heat to boiling, add 2.8gNa 2 HPO 4 12H 2 O, continue to react for 30min, slowly add 7.5mL of concentrated hydrochloric acid dropwise, cool to room temperature, filter, dissolve the solid in 4.5mL of water, pour into a separatory funnel, add 10mL of ether, shake, let stand, take the bottom liquid, spin Dry diethyl ether to get Keggin type H 3 PW 12 o 40 . Weigh 5mmolH 3 PW 12 o 40 In a 25mL round bottom flask, add 10mL of distilled water to dissolve it, slowly add 5mmol of 1-allylimidazole dropwise while stirring, react at 25°C for 48h, filter, wash the product with distilled water, and dry it under vacuum at 60°C overnight to obtain Keggin type 1- Allyl imidazolium phosphotungstic salt.

[0036] 10gNa 2 WO 4 2H 2 Dissolve O in 35mL of water, heat to boiling, slowly add 15mL of concentrated phosphoric acid, react for 8h, cool to room temperature, add 10gKCl, react for ...

Embodiment 3

[0043] Embodiment 3 (degradation reaction)

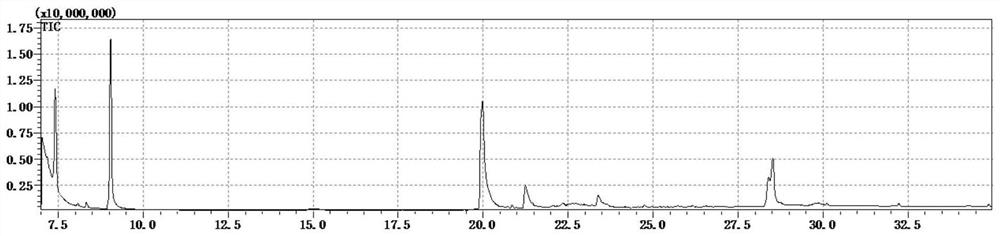

[0044] (Example 3.1) Add 1.0 g of lignin, 0.05 mmol of Cat.1 catalyst and 10 mL of water into a 25 mL three-necked flask, and react at 120° C. for 6 h. Cool to room temperature, centrifuge, precipitate the catalyst, adjust the pH of the reaction solution to 2, centrifuge, precipitate, dry and weigh, and calculate the degradation rate. The supernatant was extracted with ethyl acetate. The ethyl acetate was passed through a 0.22 μm membrane filter, and the filtrate was qualitatively analyzed by GC-MS.

[0045] (Example 3.2) Add 1.0 g of lignin, 0.05 mmol of Cat.1 catalyst and 10 mL of water into a 25 mL three-neck flask, and react for 7 h at normal pressure and temperature of 90° C. Cool to room temperature, centrifuge, precipitate the catalyst, adjust the pH of the reaction solution to 2, centrifuge, precipitate, dry and weigh, and calculate the degradation rate. The supernatant was extracted with ethyl acetate. The ethyl acetate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com