Cobalt sulfide doped nanoporous carbon electrocatalyst as well as preparation method and application thereof

A nanoporous carbon and electrocatalyst technology, applied in the direction of fuel cell half-cells and primary battery half-cells, circuits, electrical components, etc., can solve the problem of poor stability, insufficient durability, and limited resources of platinum-based catalysts. and other problems, to achieve the effect of improving electrocatalytic activity, catalytic activity, and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

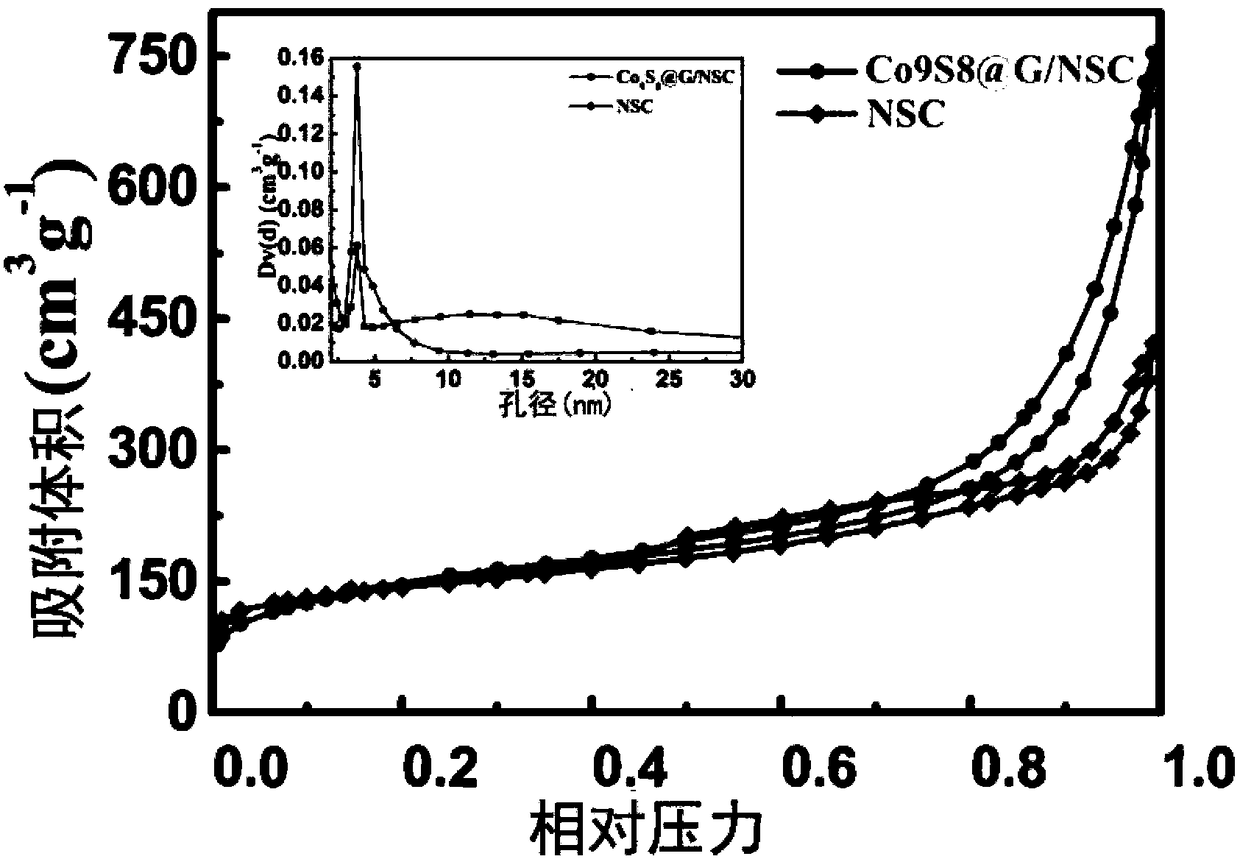

[0035]The invention provides a kind of preparation method of cobalt sulfide doped nanoporous carbon electrocatalyst, comprises the steps:

[0036] Electrospinning after the first mixing of 2-aminoterephthalic acid, water-soluble aluminum salt and organic solvent to obtain a spinning film;

[0037] Drying the spun film to obtain nitrogen-doped aluminum metal MOFs;

[0038] The thiourea, water-soluble cobalt salt, ethanol aqueous solution and n-hexane are mixed for the second time to obtain a mixed solution;

[0039] The nitrogen-doped aluminum metal MOFs and the mixed solution are coated with a two-phase interface, and solid-liquid separation is performed to obtain nitrogen-sulfur-doped cobalt-aluminum bimetallic MOFs;

[0040] in N 2 atmosphere, the nitrogen-sulfur doped cobalt aluminum bimetallic MOFs are pyrolyzed to obtain cobalt sulfide doped nanoporous carbon electrocatalysts.

[0041] In the present invention, 2-aminoterephthalic acid, water-soluble aluminum salt and ...

Embodiment 1

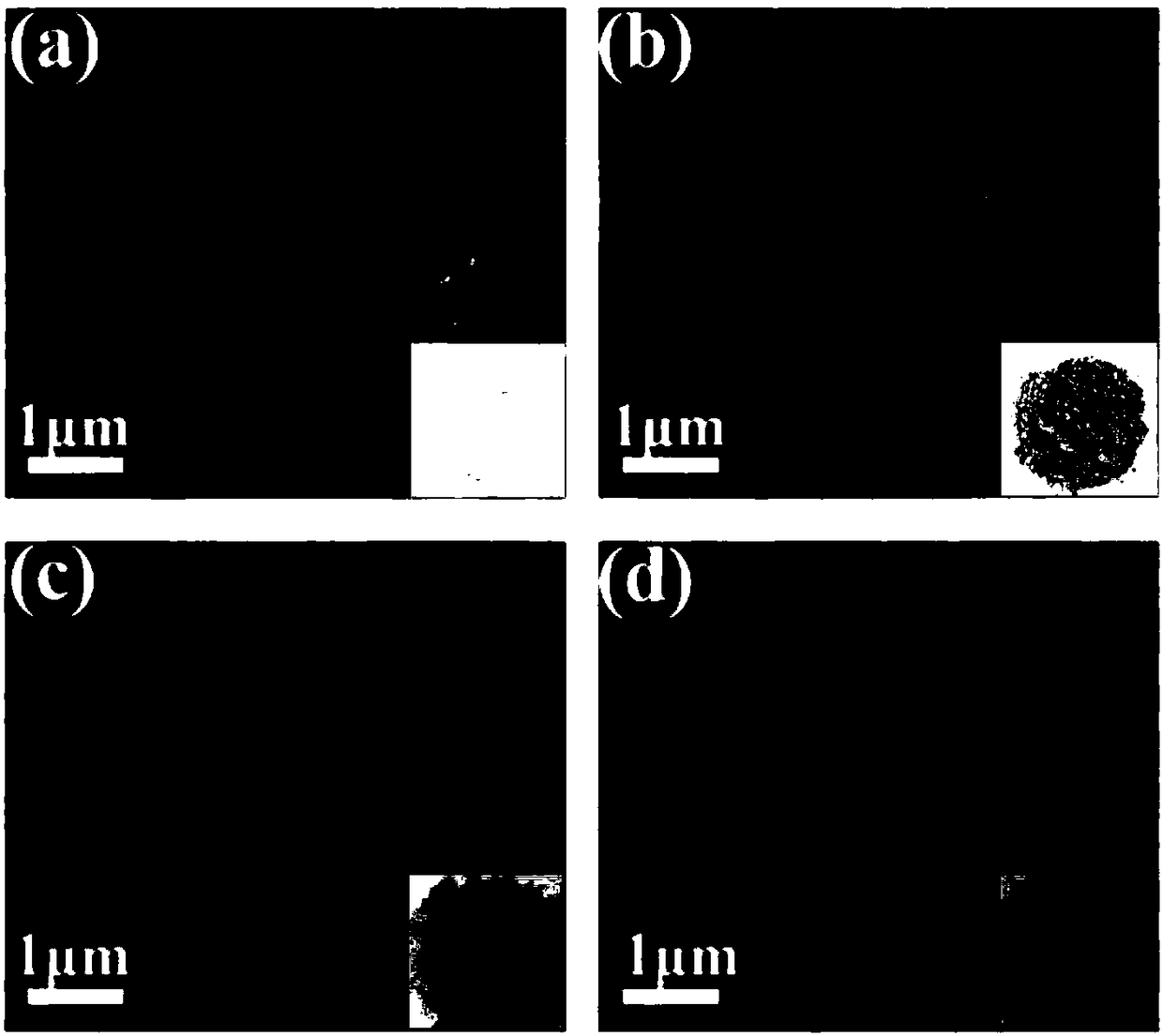

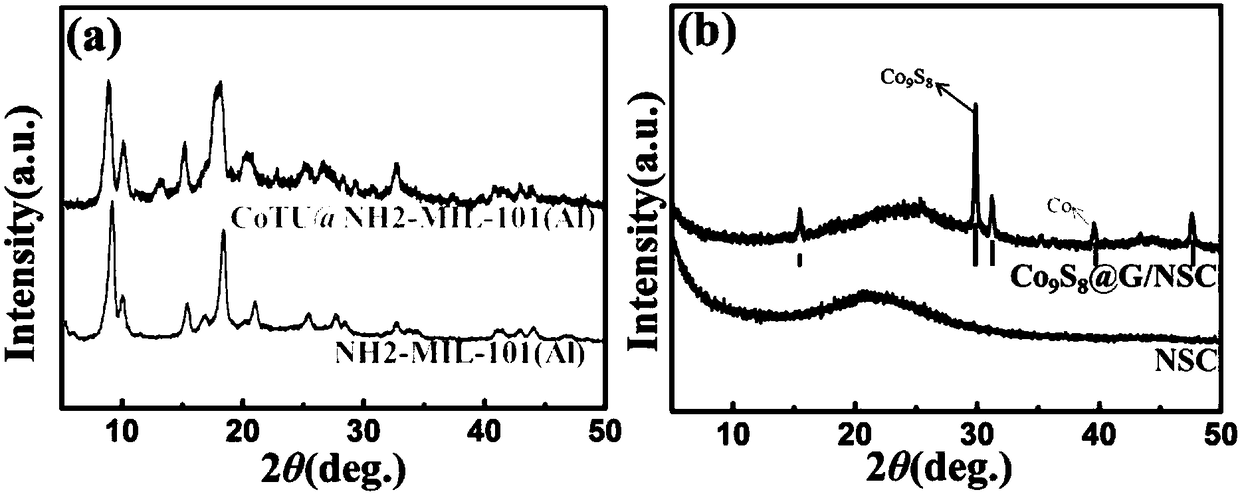

[0074] 1) Preparation of nitrogen-doped aluminum metal MOFs:

[0075] 2-aminoterephthalic acid (2.24g) and AlCl 3 ·6H 2 O (2.04g) was dissolved in 120mL N,N-dimethylformamide (DMF), and ultrasonicated for 30min to make the solution evenly mixed. Then transfer the above solution to a 10ml plastic syringe with a 18-gauge blunt needle, and perform electrospinning at a speed of 0.1-0.3ml / h. The distance is 12cm, and the thickness of the spun film is controlled at 300 μm to 400 μm; the obtained spun film is vacuum-dried at 60°C for 12 hours to obtain NH 2 -MIL-101(Al) is nitrogen-doped aluminum metal MOFs.

[0076] 2) Preparation of nitrogen-sulfur doped cobalt-aluminum bimetallic MOFs:

[0077] Thiourea (TU100mg), CoCl 2 ·6H 2 O (100 mg), dissolved in 67 mL of water-ethanol solution (3:1, v / v). The above solution was dripped into n-hexane (80mL) dropwise, and stirred at a maximum speed for 30min during the dripping process to obtain a mixed solution; the dried NH 2 -MIL-10...

Embodiment 2

[0081] 1) Preparation of nitrogen-doped aluminum metal MOFs:

[0082] 2-aminoterephthalic acid (2.5g) and AlCl 3 ·6H 2 O (2.26g) was dissolved in 130mL of N,N-dimethylformamide (DMF), and ultrasonicated for 20min to make the solution evenly mixed. Then the above solution was transferred to a 10ml plastic syringe with a 18-gauge blunt pointed needle, and electrospinning was carried out at a speed of 0.2ml / h. The spinning machine applied a voltage of 20kV, and the distance from the needle tip to the receiver tin foil was 12cm, the thickness of the spun membrane is controlled at 300μm-400μm; the obtained spun membrane is vacuum-dried at 40°C for 18h to obtain NH 2 -MIL-101(Al) is nitrogen-doped aluminum metal MOFs.

[0083] 2) Preparation of nitrogen-sulfur doped cobalt-aluminum bimetallic MOFs:

[0084] Thiourea (TU80mg), CoCl 2 ·6H 2 O (80mg), dissolved in 60mL water-ethanol solution (3:1, v / v). The above solution was dripped into normal hexane (80mL), and stirred at a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Pyrolysis temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com