Preparation method of charred boards

A wood plank and carbonization technology, applied in the field of wood, can solve problems such as high cost and insufficient carbonization, and achieve the effects of short time consumption, improved waterproof performance, and reasonable process arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

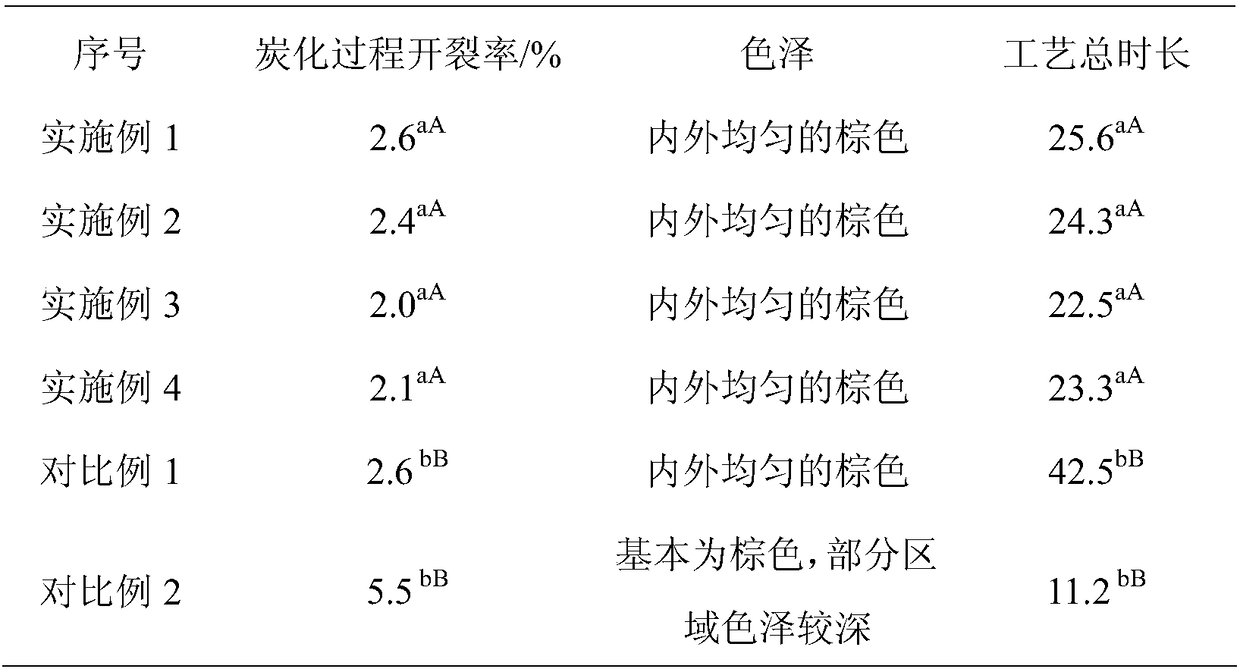

Examples

Embodiment 1

[0025] A preparation method of carbonized wood board, comprising the following steps:

[0026] (1) Preparation of preservative solution: dissolve 10 parts of boric acid, 5 parts of hydrogen peroxide, and 2 parts of vitamin C in 100 parts of water, and mix well to get final product;

[0027] (2) Preparation of treatment liquid: 1) raw materials of treatment liquid: 30 parts of EVA resin, 5 parts of edible oil, 0.5 part of copper sulfate, 1 part of ferrous sulfate, 1 part of calcium hydroxide, 5 parts of nano-titanium dioxide, 10 parts of polyethylene wax 1 part, 4 parts of diacetyl tartrate monoglyceride, 1 part of polyoxypropylene oxide glyceryl ether and 100 parts of water;

[0028] 2) The preparation method of the treatment liquid: dissolve 0.5 parts of copper sulfate, 1 part of ferrous sulfate, and 1 part of calcium hydroxide in 100 parts of water, mix well under stirring, then add 4 parts of diacetyl tartrate monoglyceride and polyoxygen 1 part of propylene oxide ethylene...

Embodiment 2

[0035] A preparation method of carbonized wood board, comprising the following steps:

[0036] (1) Preparation of preservative solution: 12 parts of boric acid, 6 parts of hydrogen peroxide, and 3 parts of vitamin C are dissolved in 120 parts of water, and mixed evenly;

[0037] (2) Preparation of treatment liquid: 1) raw materials of treatment liquid: 35 parts of EVA resin, 10 parts of edible oil, 1 part of copper sulfate, 1.5 parts of ferrous sulfate, 1.5 parts of calcium hydroxide, 8 parts of nano-titanium dioxide, 12 parts of polyethylene wax 5 parts, 5 parts of diacetyl tartrate monoglyceride, 2 parts of polyoxypropylene oxide glyceryl ether and 105 parts of water;

[0038] 2) Preparation method of treatment solution: dissolve 1 part of copper sulfate, 1.5 parts of ferrous sulfate, and 1.5 parts of calcium hydroxide in 105 parts of water, mix well under stirring, then add 5 parts of diacetyl tartrate monoglyceride and polyoxygen 2 parts of propylene oxide ethylene glycer...

Embodiment 3

[0045] A preparation method of carbonized wood board, comprising the following steps:

[0046](1) Preparation of preservative solution: dissolve 15 parts of boric acid, 8 parts of hydrogen peroxide, and 4 parts of vitamin C in 140 parts of water, and mix well to get final product;

[0047] (2) Preparation of treatment liquid: 1) raw materials of treatment liquid: 40 parts of EVA resin, 12 parts of edible oil, 1.5 parts of copper sulfate, 2 parts of ferrous sulfate, 2 parts of calcium hydroxide, 12 parts of nano-titanium dioxide, 16 parts of polyethylene wax 5 parts, 5 parts of diacetyl tartrate monoglyceride, 2.5 parts of polyoxypropylene oxide glyceryl ether and 112 parts of water;

[0048] 2) Preparation method of treatment solution: dissolve 1.5 parts of copper sulfate, 2 parts of ferrous sulfate, and 2 parts of calcium hydroxide in 112 parts of water, mix well under stirring, then add 5 parts of diacetyl tartrate monoglyceride and polyoxygen 2.5 parts of propylene oxide e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com