Preparation method and application of magnetic porous supermolecular cyclodextrin-adsorbing material

An adsorption material, cyclodextrin technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., to achieve good stability and dispersibility, improve separation efficiency, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

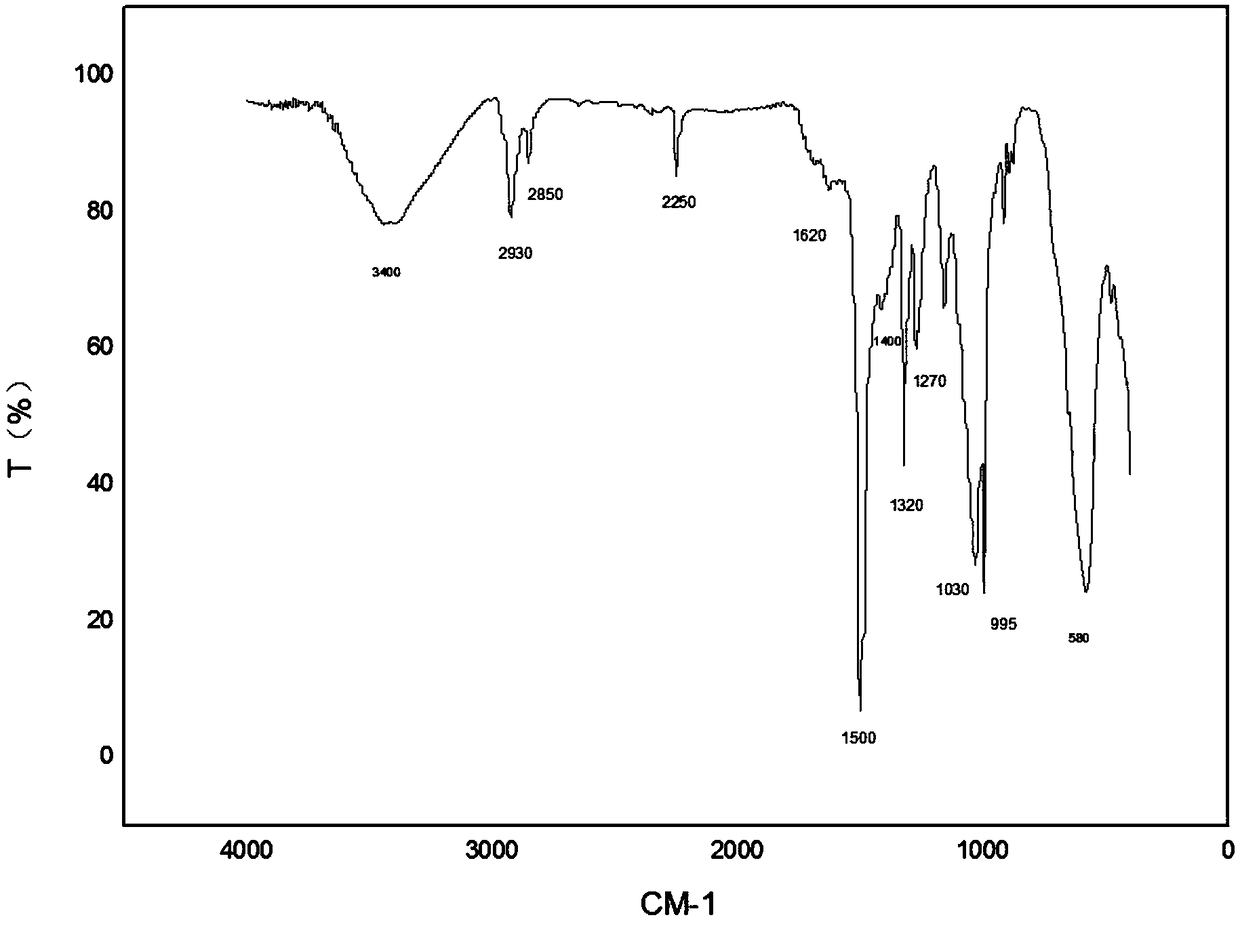

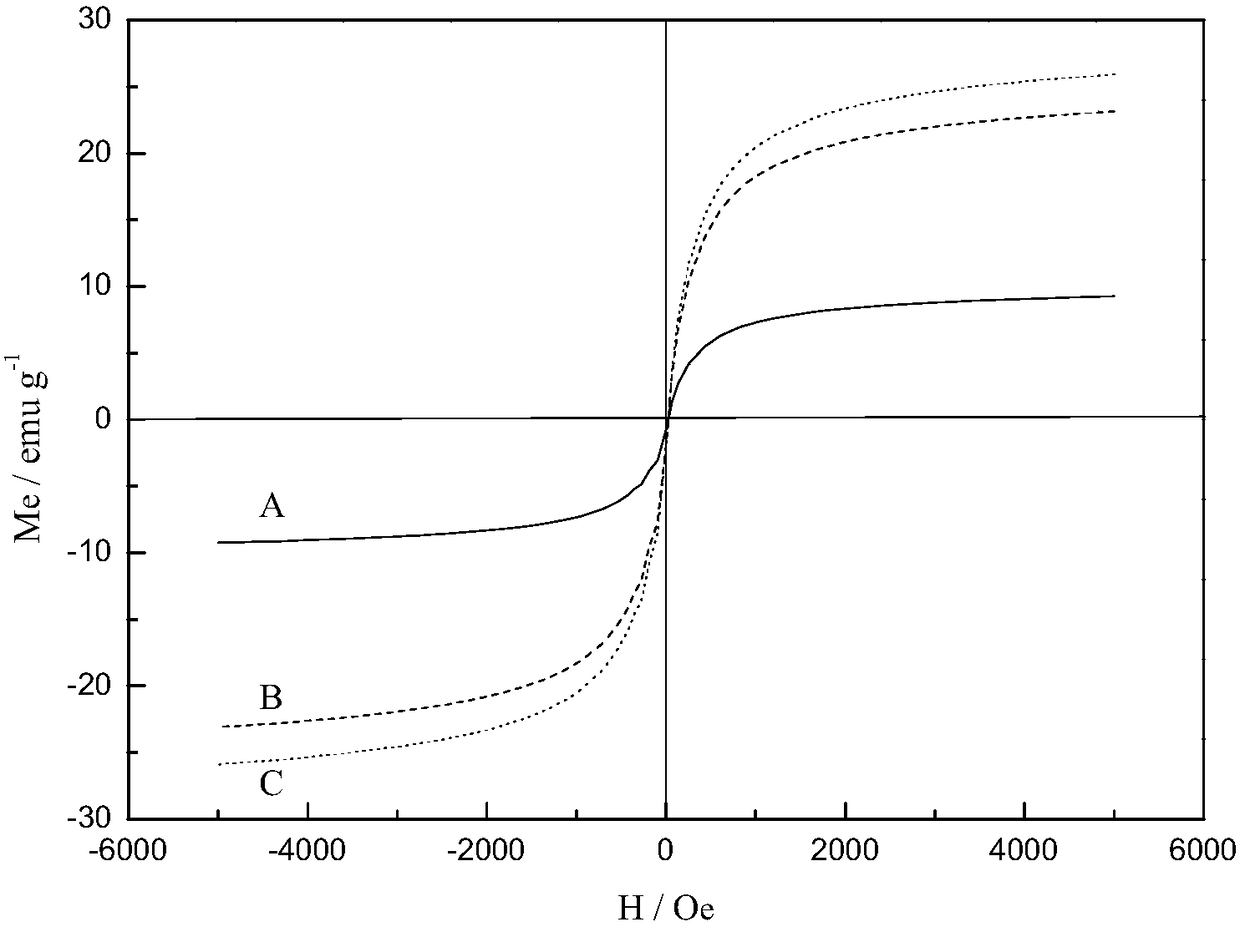

Method used

Image

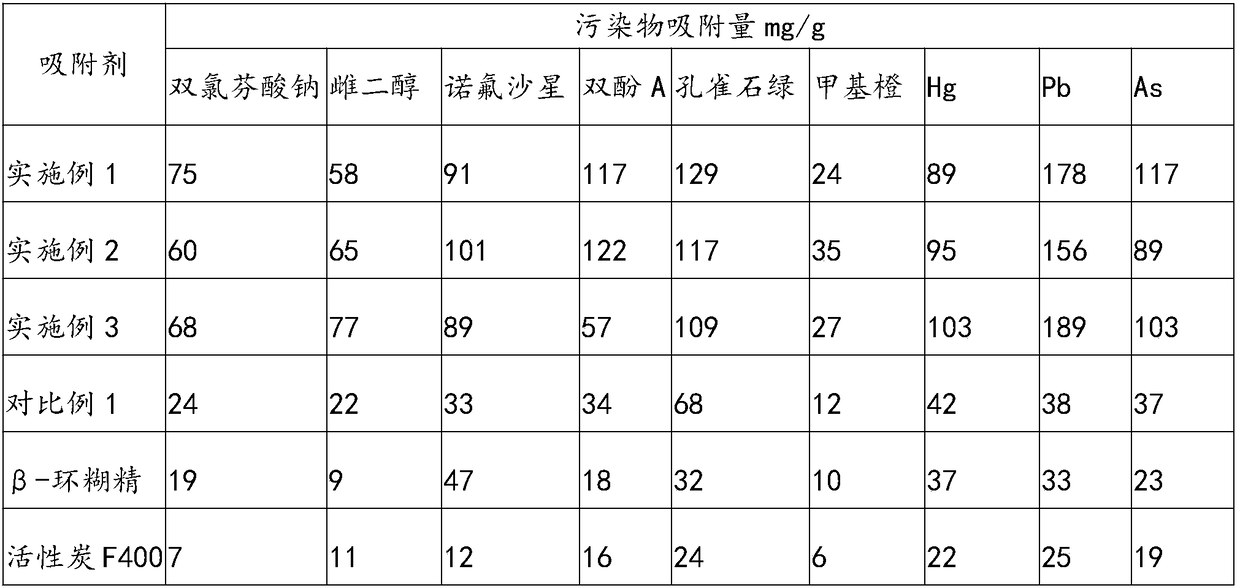

Examples

Embodiment 1

[0025] A method for preparing a magnetic porous supramolecular cyclodextrin adsorption material, comprising the steps of:

[0026] 1) Under nitrogen protection, add 10g of β-cyclodextrin, 5g of tetrafluoroterephthalonitrile and 10g of potassium carbonate into the flask, then add 100ml of anhydrous tetrahydrofuran into the flask, heat up to 80°C for reaction, and stir at a speed of 500rpm After 25 hours, the reaction was complete, cooled to room temperature, and the product was washed several times with 10 wt% hydrochloric acid until potassium carbonate was removed (the filtrate was detected by barium chloride without precipitation), and then freeze-dried to obtain orange powder PBCD;

[0027] 2) Weigh 5g FeCl 3 ·6H 2 0.2g FeCl 2 4H 2 0 and 15g of the PBCD obtained in step 1) were placed in a reactor, and 120ml of water was added to the reactor, and then the reactor was heated to 80°C under nitrogen protection and stirring, kept for 5 minutes, and then concentrated ammonia w...

Embodiment 2

[0030] A method for preparing a magnetic porous supramolecular cyclodextrin adsorption material, comprising the steps of:

[0031] 1) Under nitrogen protection, add 20g of β-cyclodextrin, 8g of tetrafluoroterephthalonitrile and 10g of potassium carbonate into the flask, then add 250ml of anhydrous tetrahydrofuran into the flask, heat up to 70°C for reaction, and stir at a speed of 800rpm Reaction was complete after 20 hours, cooled to room temperature, and the product was washed several times with 10wt% nitric acid until potassium carbonate was removed (the filtrate was detected by barium chloride without precipitation), and then freeze-dried to obtain orange powder PBCD;

[0032] 2) Weigh 8g FeCl 3 ·6H 2 0.3g FeCl 2 4H 20 and 40g of the PBCD obtained in step 1) were placed in a reactor, and 220ml of water was added to the reactor, and then the reactor was heated to 100°C under nitrogen protection and stirring, kept for 15 minutes, and concentrated ammonia water was added d...

Embodiment 3

[0035] A method for preparing a magnetic porous supramolecular cyclodextrin adsorption material, comprising the steps of:

[0036] 1) Under nitrogen protection, add 8g of β-cyclodextrin, 2.2g of tetrafluoroterephthalonitrile and 15g of potassium carbonate in the flask, then add 80ml of anhydrous tetrahydrofuran into the flask, heat up to 90°C and react at a speed of 1000rpm After stirring for 40 hours, the reaction was complete, cooled to room temperature, and the product was washed several times with 10 wt% nitric acid until potassium carbonate was removed (the filtrate was detected by barium chloride without precipitation), and then freeze-dried to obtain orange powder PBCD;

[0037] 2) Weigh 5g FeCl 3 ·6H 2 0.2g FeCl 2 4H 2 0 and 50 g of the PBCD obtained in step 1) were placed in a reactor, and 100 ml of water was added to the reactor, and then the reactor was heated to 80° C. under nitrogen protection and stirring, kept for 30 minutes, and concentrated ammonia water wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com