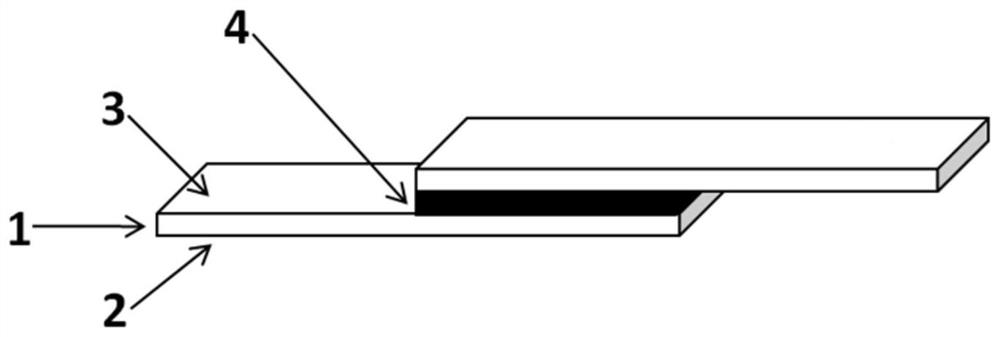

A kind of welding joint and welding method of low-resistance yttrium-based high-temperature superconductor based on nano-silver solder

A welding method and technology of high-temperature superconducting strips, which are applied in welding/fusion connections, conductors, welding equipment, etc., can solve problems such as cracks, joint performance degradation, and performance degradation of yttrium-based high-temperature superconducting strips. Simple operation, short welding time, no effect on superconductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 A kind of welding of low-resistance yttrium-based high-temperature superconductor based on nano-silver solder

[0027] A welding method of a low-resistance yttrium-based high-temperature superconductor based on nano-silver solder, comprising the following steps:

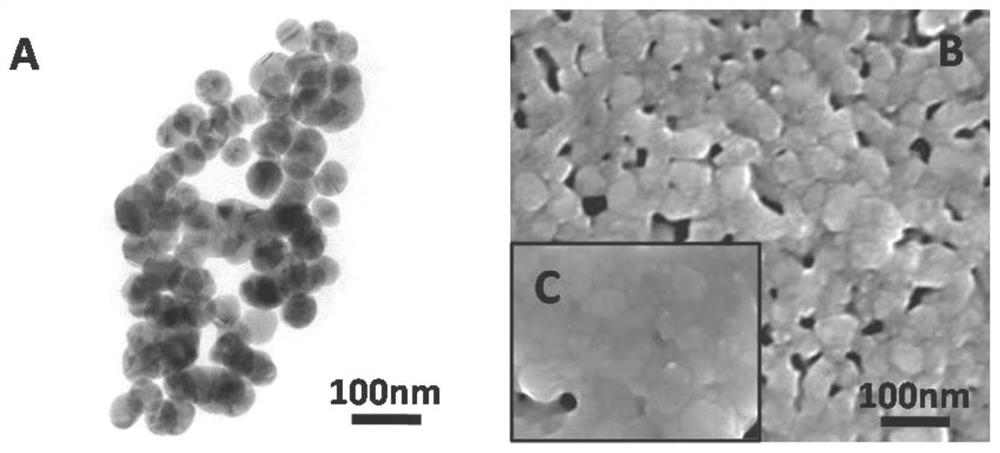

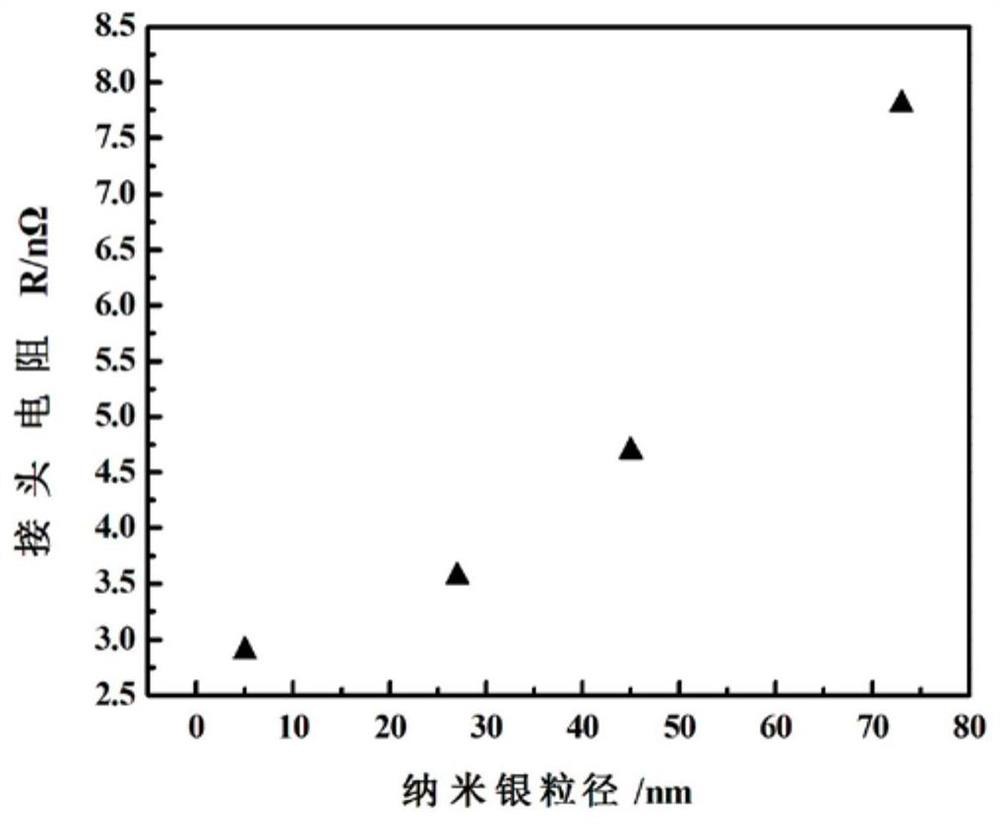

[0028] (1) Preparation of nano-silver solder: Stir and mix 1L of sodium citrate solution with a concentration of 10g / L and 3.75L of deionized water and heat to 80°C, add 85mL of silver nitrate solution with a concentration of 10g / L to the reaction kettle middle. Subsequently, 100 mL of sodium borohydride solution with a concentration of 1 g / L was quickly added to the above reaction system, and after vigorous stirring at 80° C. for 1.5 h, it was gradually cooled to room temperature to obtain a monodisperse nano-silver colloidal dispersion with a particle size of 5 nm;

[0029] (2) Preparation of monodisperse nano-silver ethanol dispersion: the monodisperse nano-silver colloidal dispersion of parti...

Embodiment 2

[0031] Embodiment 2 Welding of a low-resistance yttrium-based high-temperature superconductor based on nano-silver solder

[0032] A welding method of a low-resistance yttrium-based high-temperature superconductor based on nano-silver solder, comprising the following steps:

[0033](1) Preparation of nano-silver solder: Stir and mix 1L of sodium citrate solution with a concentration of 10g / L and 3.75L of deionized water and heat to 80°C, add 85mL of silver nitrate solution with a concentration of 10g / L to the reaction kettle middle. Subsequently, 100 mL of sodium borohydride solution with a concentration of 1 g / L was quickly added to the above reaction system, stirred vigorously at 80° C. for 1.5 h, and then gradually cooled to room temperature to obtain a monodisperse nano-silver colloid solution (S1) with a particle size of 5 nm. Under the condition of vigorous stirring at 80° C., 2 L of S1 solution was added to 400 mL of a mixed solution of 10 g / L sodium citrate solution a...

Embodiment 3

[0036] Embodiment 3 Welding of a low-resistance yttrium-based high-temperature superconductor based on nano-silver solder

[0037] A welding method of a low-resistance yttrium-based high-temperature superconductor based on nano-silver solder, comprising the following steps:

[0038] (1) Preparation of nano-silver solder: Stir and mix 1L of sodium citrate solution with a concentration of 10g / L and 3.75L of deionized water and heat to 80°C, add 85mL of silver nitrate solution with a concentration of 10g / L to the reaction kettle middle. Subsequently, 100 mL of sodium borohydride solution with a concentration of 1 g / L was quickly added to the above reaction system, stirred vigorously at 80° C. for 1.5 h, and then gradually cooled to room temperature to obtain a monodisperse nano-silver colloid solution (S1) with a particle size of 5 nm. Under the condition of vigorous stirring at 80° C., 2 L of S1 solution was added to 400 mL of a mixed solution of 10 g / L sodium citrate solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com