Green preparation method for metal oxide nano material

A technology of nanomaterials and oxides, applied in chemical instruments and methods, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of non-compliance with green synthesis and clean production, increase costs, etc., and achieve easy production and cost saving , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

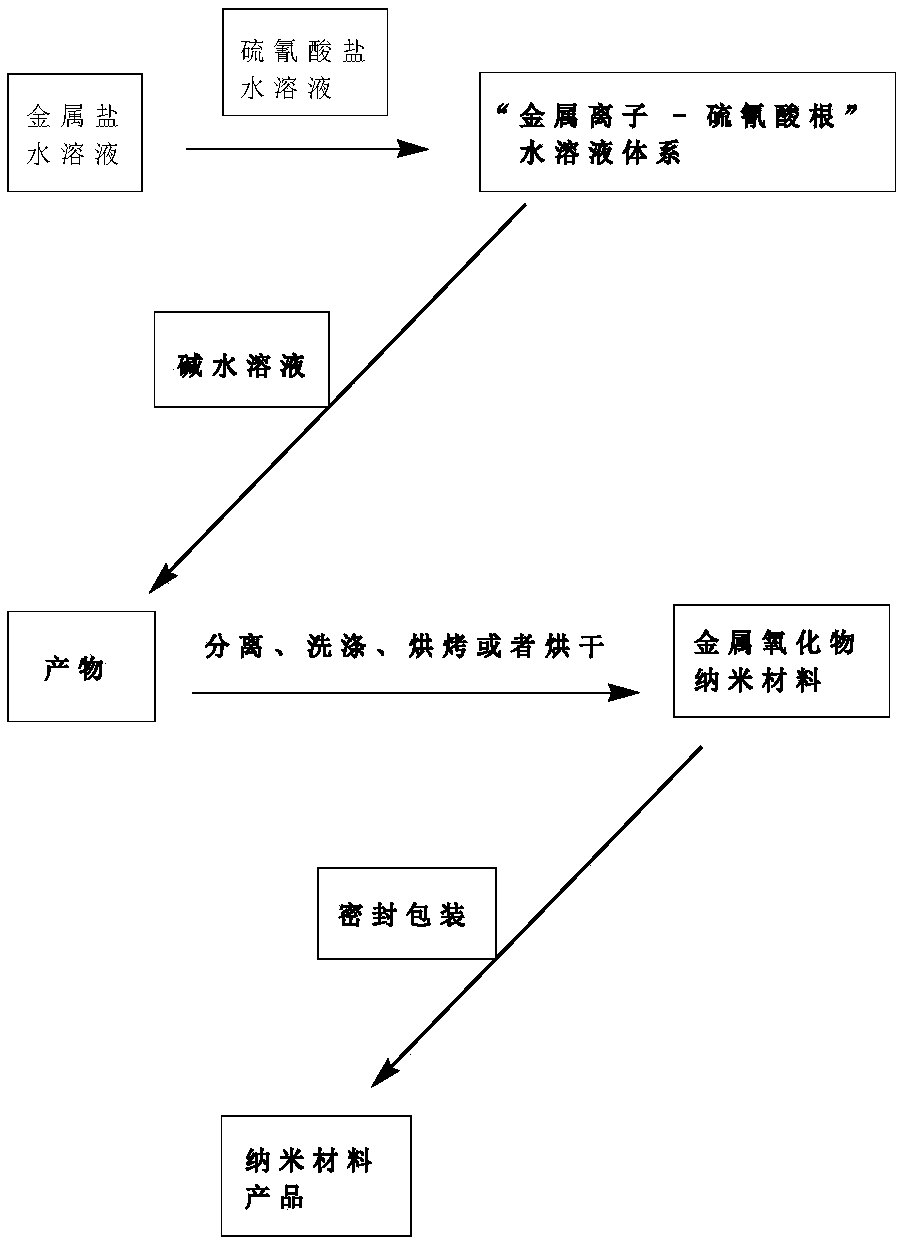

Method used

Image

Examples

Embodiment 1

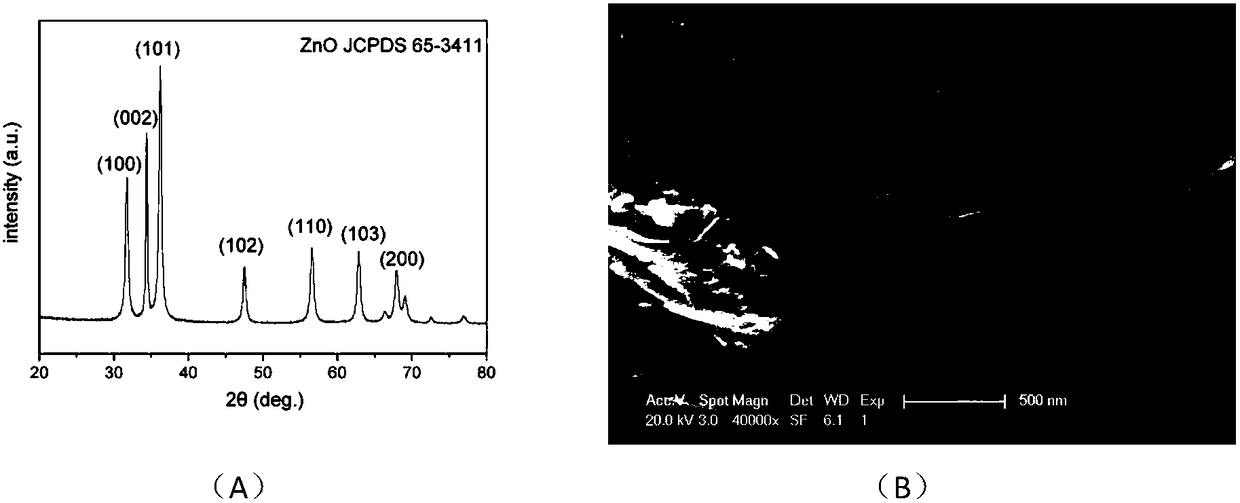

[0048] 0.5mol / L of ZnSO 4 Mix 10ml of the solution with 10ml of 1mol / L NaSCN solution, and after fully reacting, add 12ml of 1mol / L NaOH. ZnSO 4 and NaSCN are equivalent, and the ratio of substances is 1:2; NaOH is excessive, and ZnSO 4 The substance ratio with NaOH is 1:2.4. After standing for 2 hours, filter with suction, wash the solid precipitate, and then dry it at 60°C to obtain the ZnO nanomaterial sample (if the sample is baked at 300°C for 2 hours, the sample is still ZnO). XRD and SEM of the sample (see figure 2 ) analysis is as follows, the detection result is flaky ZnO (JCPDS 65-3411), the length can reach 1μm, and the thickness is about 20nm.

[0049] Experiments have proved that this kind of flaky zinc oxide has good photocatalytic activity. This zinc oxide is a semiconductor material that has important applications in oxide thin-film solar energy; it can also be used as a filler material in composite materials.

Embodiment 2

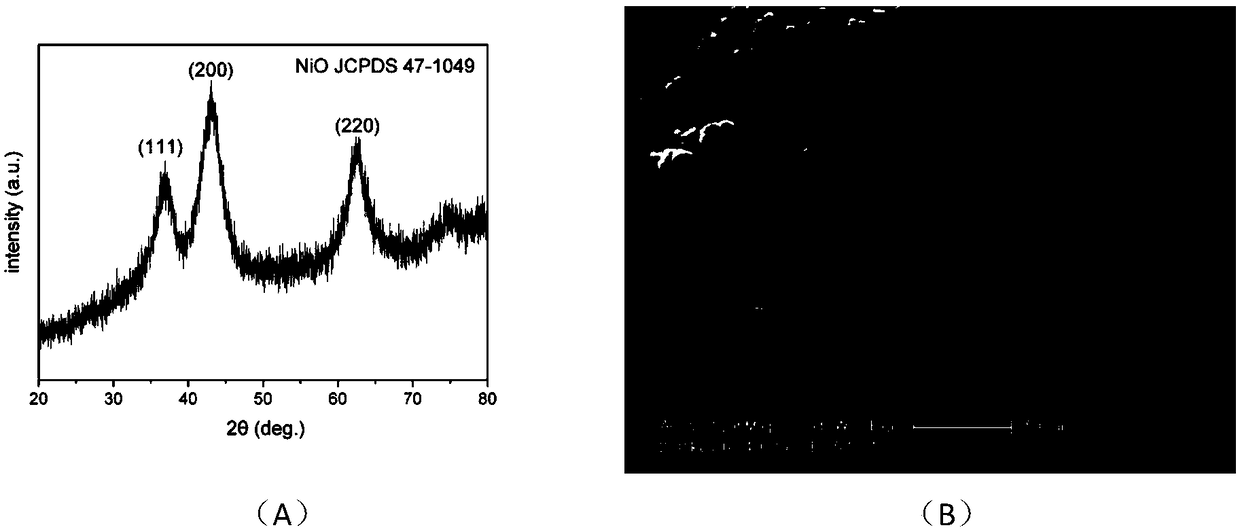

[0051] 0.2mol / L NiSO 4 Mix 50ml of the solution with 100ml of 0.2mol / L KSCN solution evenly, and then add the mixed solution dropwise to 100ml of 0.2mol / L KOH aqueous solution. NiSO 4 It is equivalent to KSCN, and the molar ratio of the substance is 1:2; NiSO 4 The substance molar ratio with KOH is 1:2. After mixing evenly, let it stand for 3~6h. Then, centrifuge in a centrifuge at 4000r / min for 5min to separate the precipitate, wash it with deionized water and alcohol several times, and then dry it in a drying oven (50°C) to obtain light green β-Ni(OH) 2 precursor, again at 280 0 C and baked for 2h, the NiO nanomaterial sample can be obtained. XRD and SEM of the sample (see image 3 ) analysis is as follows, the test result is granular NiO (JCPDS 47-1049), the particle size is 30-70nm.

[0052] Experiments have proved that this nickel oxide nanomaterial can degrade organic matter well under the action of photocatalysis.

Embodiment 3

[0054] 0.05mol / L of Ti(SO 4 ) 2 Mix 50ml of the solution with 100ml of 0.1mol / L NaSCN solution evenly, and then add it to 75ml of 0.2mol / L NaOH solution. Ti(SO 4 ) 2 and NaSCN are equivalent, and the molar ratio of the substances is 1:4; Ti(SO 4 ) 2 The molar ratio of the substance to NaOH is 1:6. After mixing evenly, let stand for 2 hours, suction filter, wash, dry at 60° C., and bake at 300° C. for 2 hours to obtain a titanium oxide nanomaterial sample. XRD and SEM of the sample (see Figure 4 ) analysis is as follows, the detection result is very small particles, and the XRD analysis pattern has no signal peak, which is an amorphous amorphous material.

[0055] It can be used as a doping material to improve the performance of thin-film solar cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com