Industrial and urban mixed sewage stable operation control method

A mixed sewage, stable operation technology, applied in water treatment parameter control, chemical instruments and methods, special compound water treatment, etc., can solve difficult biological treatment system protection, effective prediction of industrial wastewater toxicity impact, toxicity analysis stability needs to be improved and other problems, to achieve the effects of not being able to objectively reflect microbial activity, good promotion and application prospects, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Activated carbon-combined activated sludge cultivation: 2.0 mL of aerobic activated sludge mixture was directly taken from the biological aeration tank of a sewage treatment plant in Shanghai and inoculated into 30 mL of beef extract-peptone culture solution, and incubated at 37 °C and 200 r After shaking and culturing for 24 hours, add 5.0 g of coconut shell powdered activated carbon, mix evenly, filter through a 0.45um microporous membrane, and store in a refrigerator at 4°C until use, denoted as A.

[0026] (2) Zeolite composite nitrifying bacteria culture: Take 5.0 mL of aerobic activated sludge mixture directly from the biological aeration tank of a sewage treatment plant in Shanghai and inoculate it into a sterile Erlenmeyer flask containing 30 mL of nitrifying bacteria enrichment medium medium, 28°C constant temperature and dark culture until NO 3 - When the formation rate of -N reaches 92%, add 3.0g of natural zeolite powder, mix evenly, filter through a 0....

Embodiment 2

[0029] In this embodiment, anaerobic / anoxic / aerobic (A 2 / O) Activated sludge denitrification system treats sewage from a sewage plant in Shanghai, A 2 The effective volume of / O reactor is 2.5m 3 , anaerobic: anoxic: aerobic = 1:1:1, the anaerobic zone and the anoxic zone are equipped with agitation, the DO in the aerobic zone is controlled at 2.5mg / L, the sludge reflux ratio is 50%, and the digestate reflux ratio is 100%, the mud age is controlled at 12 days, and a certain urban sewage is used as the treatment object (see Table 1 for influent water quality). At the water inlet end of the reactor, a multi-channel biosensor equipped with a microbial electrode A is set to detect the toxicity of the influent water quality to the activated sludge; at the end of the aerobic reaction tank, a multi-channel biosensor equipped with a microbial electrode B is set, It is used to detect the toxicity of nitrification tank sewage to nitrifying bacteria.

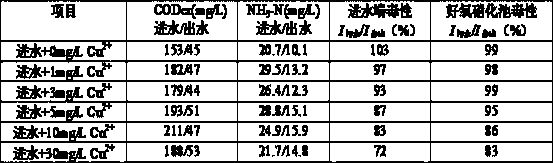

[0030] During the experiment, d...

Embodiment 3

[0034] In this embodiment, anaerobic / anoxic / aerobic (A 2 / O) Activated sludge denitrification system treats sewage from a sewage plant in Shanghai, A 2 The effective volume of / O reactor is 2.5m 3, anaerobic: anoxic: aerobic=1:0.5:1.5, the anaerobic zone and the anoxic zone are equipped with agitation, the DO in the aerobic zone is controlled at 2.5mg / L, the sludge reflux ratio is 50%, and the digestate reflux ratio is 100%, the mud age is controlled at 15 days, and a certain urban sewage is used as the treatment object (see Table 2 for influent water quality). At the water inlet end of the reactor, a multi-channel biosensor equipped with a microbial electrode A is set to detect the toxicity of the influent water quality to the activated sludge; at the end of the aerobic reaction tank, a multi-channel biosensor equipped with a microbial electrode B is set, It is used to detect the toxicity of nitrification tank sewage to nitrifying bacteria.

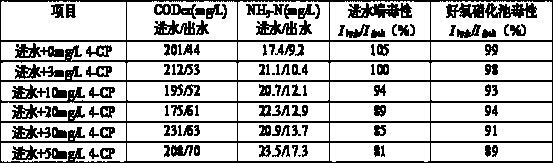

[0035] During the experiment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com