Lead-free ceramic material with high energy density and charging and discharging properties and preparation method of lead-free ceramic material

A technology with charge-discharge performance and high energy storage density, applied in the field of functional ceramic materials, can solve the problems of decreased current density and power density, low energy storage effect of barium titanate-based materials, and reduced cycle life of capacitors, etc., and achieves good temperature stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

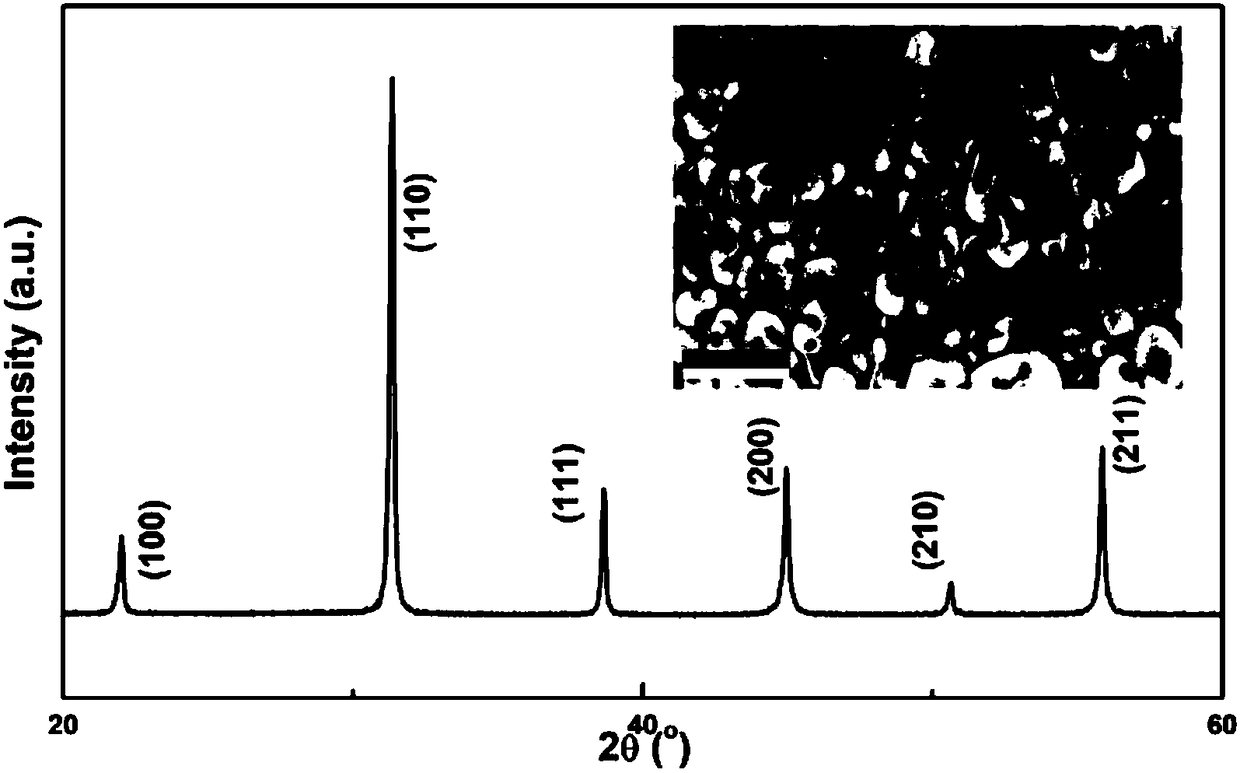

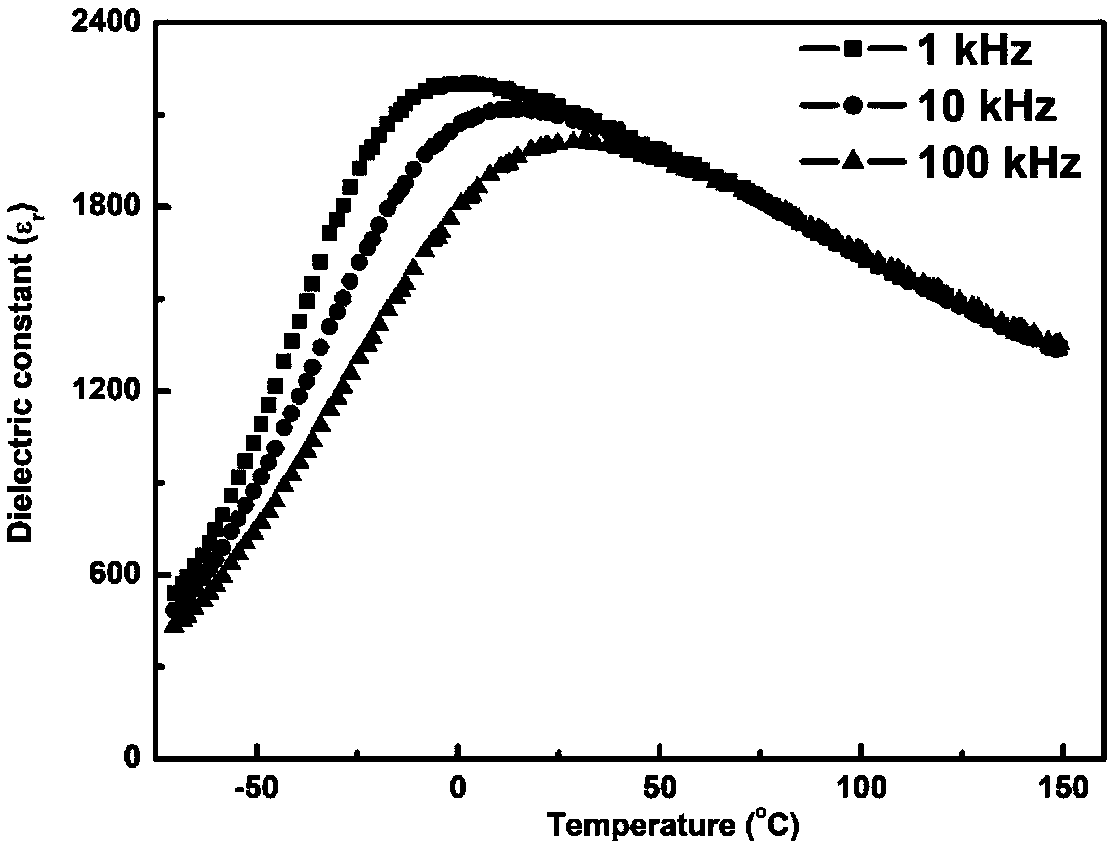

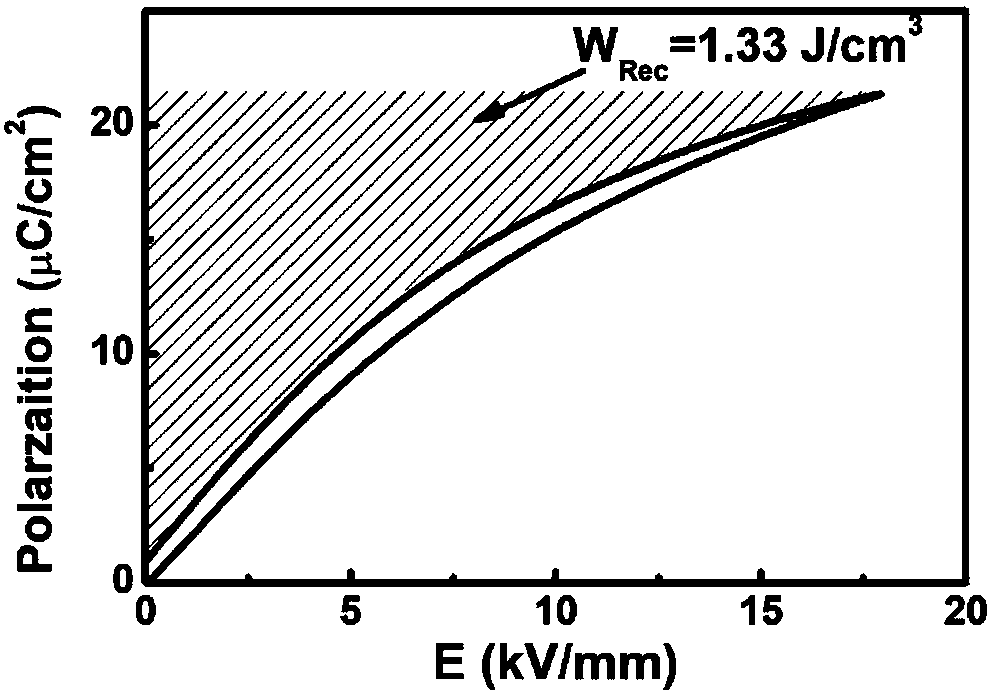

[0028] The preparation method of the lead-free ceramic material with high energy storage density and charge-discharge performance adopts the following steps:

[0029] (1) Select the national medicine reagent BaCO with a purity greater than 99% 3 , TiO 2 , Bi 2 o 3 , Na 2 CO 3 , In 2 o 3 , ZrO 2 As a raw material for lead-free ceramic materials. According to the chemical formula 0.9BaTiO 3 -0.1 (Bi 0.9 Na 0.1 )(In 0.8 Zr 0.2 )O 3 Weigh the material, add absolute ethanol and zirconia balls into the nylon tank for ball milling, discharge, and dry. The ball milling time was 8 hours, and the drying temperature was 120°C. Put the dried powder into a corundum crucible, cover the crucible after compaction, put it into a muffle furnace for calcination, raise it to 950°C at 5°C / min, keep it warm for 3 hours, cool it down to room temperature, and take it out with a grinder. Grinding in a bowl, and calcining in a corundum crucible again, the heating rate and holding time are...

Embodiment 2

[0037] The preparation method of the lead-free ceramic material with high energy storage density and charge-discharge performance adopts the following steps:

[0038] (1) Select the national medicine reagent BaCO with a purity greater than 99% 3 , TiO 2 , Bi 2 o 3 , Na 2 CO 3 , In 2 o 3 , ZrO 2 As a raw material for lead-free ceramic materials. According to the chemical formula 0.9BaTiO 3 -0.1 (Bi 0.9 Na 0.1 )(In 0.8 Zr 0.2 )O 3 Weigh the material, add absolute ethanol and zirconia balls into the nylon tank for ball milling, discharge, and dry. The ball milling time was 8 hours, and the drying temperature was 120°C. Put the dried powder into a corundum crucible, cover the crucible after compaction, put it into a muffle furnace for calcination, raise it to 950°C at 5°C / min, keep it warm for 2 hours, cool it to room temperature, and take it out with a grinder. Grinding in a bowl, and calcining in a corundum crucible again, the heating rate and holding time are th...

Embodiment 3

[0046] The preparation method of the lead-free ceramic material with high energy storage density and charge-discharge performance adopts the following steps:

[0047] (1) Select the national medicine reagent BaCO with a purity greater than 99% 3 , TiO 2 , Bi 2 o 3 , Na 2 CO 3 , In 2 o 3 , ZrO 2 As a raw material for lead-free ceramic materials. According to the chemical formula 0.9BaTiO 3 -0.1 (Bi 0.9 Na 0.1 )(In 0.8 Zr 0.2 )O 3 Weigh the material, add absolute ethanol and zirconia balls into the nylon tank for ball milling, discharge, and dry. The ball milling time was 8 hours, and the drying temperature was 120°C. Put the dried powder into a corundum crucible, cover the crucible after compaction, put it into a muffle furnace for calcination, raise it to 950°C at 5°C / min, keep it warm for 3 hours, cool it down to room temperature, and take it out with a grinder. Grinding in a bowl, and calcining in a corundum crucible again, the heating rate and holding time a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com