Co-pyrolysis method for alkaline residues and discarded printed wiring board

A waste circuit board, co-pyrolysis technology, applied in the field of resource utilization, can solve the problems of toxic substances polluting the environment, polluting the environment, and endangering health, and achieve the effects of solving environmental pollution, simple operation, and reducing recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

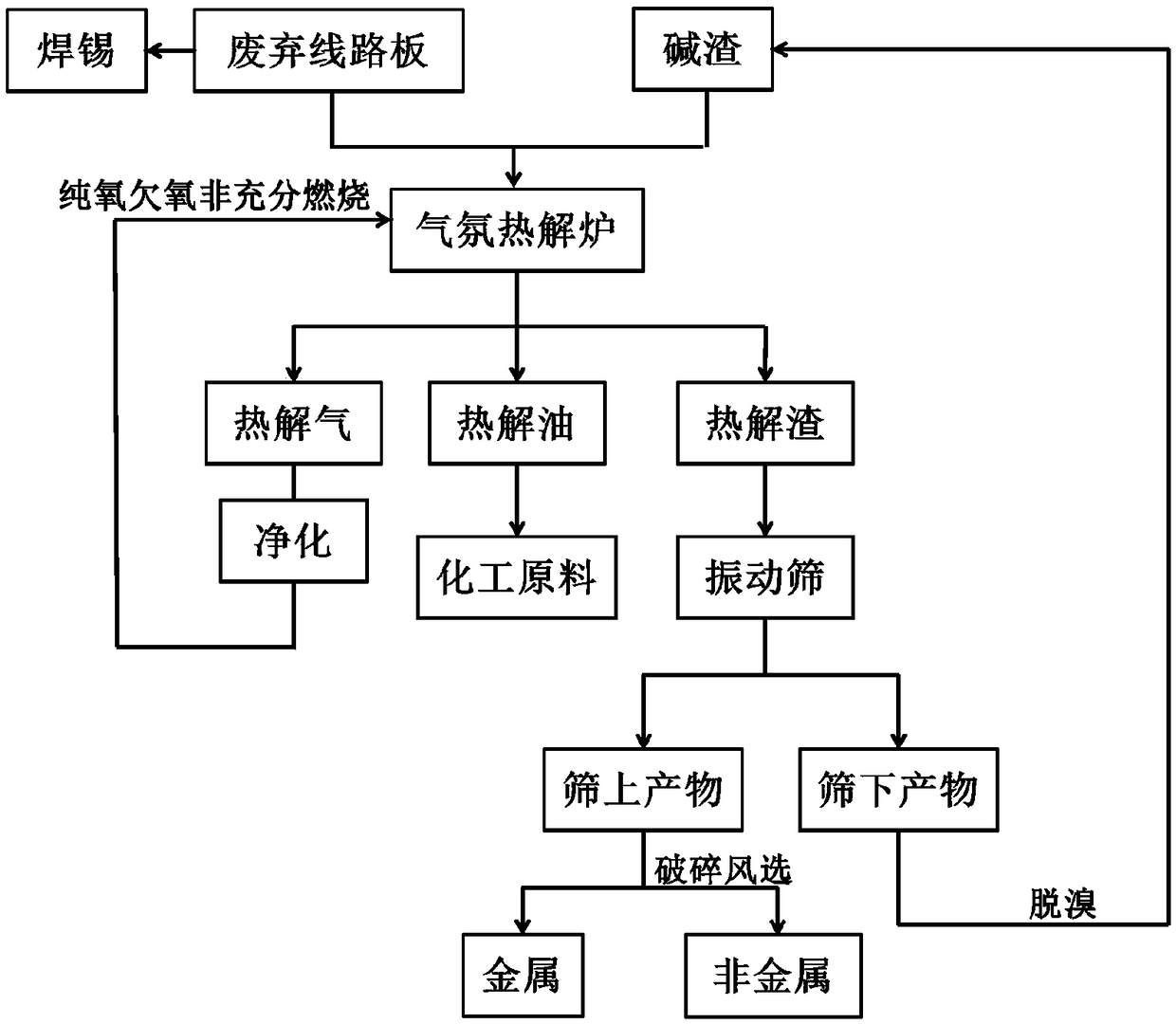

Embodiment 1

[0033] Take a waste circuit board without pre-breaking, disassemble the electronic components and recycle the solder, mix the alkali slag and the waste circuit board at a ratio of 2:1, carry out insufficient oxygen incomplete combustion, and directly heat and pyrolyze it. The amount is 0.6 times the theoretical molar amount of oxygen required for the full combustion of clean gas. The temperature in the furnace is guaranteed to be 700°C, the heating rate is controlled at 30°C / min, and the temperature is kept constant for 30 minutes. During this period, the volatiles are recycled through the condensation system. Pyrolysis gas, after the pyrolysis gas is purified by the alkali bottle, enters the gas storage tank for collection, the pyrolysis slag is separated by a 16-mesh standard sieve, and the products on the sieve are crushed and sorted to obtain metal materials and non-metal materials, and the metal materials are sent to In smelters, non-metallic materials are used as storage ...

Embodiment 2

[0035]Take a waste circuit board without pre-breaking, disassemble the electronic components and recycle the solder, mix the alkali slag and the waste circuit board at a ratio of 3:1, carry out insufficient oxygen incomplete combustion and directly heat pyrolysis, relative to the introduction of oxygen The amount is 0.6 times of the theoretical molar amount of oxygen required for the full combustion of clean gas. The temperature in the furnace is guaranteed to be 750°C, the heating rate is controlled at 20°C / min, and the temperature is kept constant for 50 minutes. During this period, the volatiles are recycled through the condensation system. Pyrolysis gas, after the pyrolysis gas is purified by the alkali bottle, enters the gas storage tank for collection, the pyrolysis slag is separated by a 16-mesh standard sieve, and the products on the sieve are crushed and sorted to obtain metal materials and non-metal materials, and the metal materials are sent to In smelters, non-metal...

Embodiment 3

[0037] Take a waste circuit board without pre-breaking, disassemble the electronic components and recycle the solder, mix the alkali slag and the waste circuit board at a ratio of 3:1, carry out insufficient oxygen incomplete combustion and directly heat pyrolysis, relative to the introduction of oxygen The amount is 0.6 times the theoretical molar amount of oxygen required for the full combustion of clean gas. The furnace temperature is guaranteed to be 800°C, the heating rate is controlled at 30°C / min, and the temperature is kept constant for 30 minutes. During this period, the volatiles are recycled through the condensation system. Pyrolysis gas, after the pyrolysis gas is purified by the alkali bottle, enters the gas storage tank for collection, the pyrolysis slag is separated by a 16-mesh standard sieve, and the products on the sieve are crushed and sorted to obtain metal materials and non-metal materials, and the metal materials are sent to In smelters, non-metallic mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com