Preparation method of cerium-rich magnet used for driving motor

A driving motor and cerium-rich technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, circuits, etc., can solve the problems of long process, many rare-earth permanent magnet preparation procedures, oxidation, etc., so as to reduce the sintering temperature and benefit Coercive force, the effect of preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

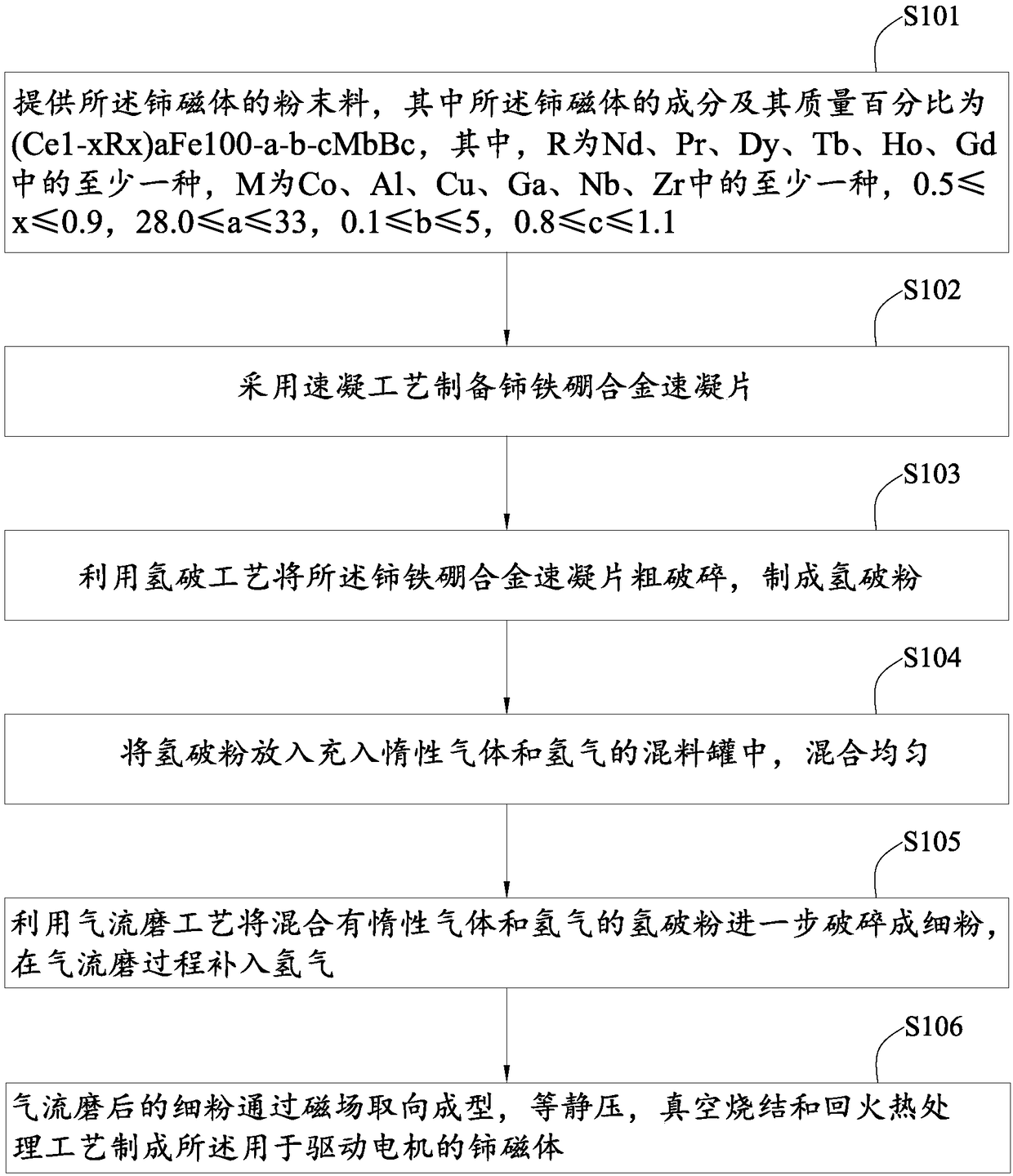

[0027] see figure 1 , which is a flow chart of a method for preparing a cerium-rich magnet for driving a motor provided by the present invention, which includes the following steps:

[0028] S101: Provide the powder material of the cerium-rich magnet, wherein the composition and mass percentage of the cerium-rich magnet are (Ce 1-x R x ) a Fe 100-a-b-c m b B c , wherein, R is at least one of Nd, Pr, Dy, Tb, Ho, Gd, M is at least one of Co, Al, Cu, Ga, Nb, Zr, 0.5≤x≤0.9, 28.0≤a ≤33, 0.1≤b≤5, 0.8≤c≤1.1;

[0029] S102: Prepare cerium-iron-boron alloy quick-setting sheet by using quick-setting process;

[0030] S103: Coarsely crushing the cerium-iron-boron alloy quick-setting sheet by using a hydrogen crushing process to make a hydrogen crushing powder;

[0031] S104: put the hydrogen powder into a mixing tank filled with inert gas and hydrogen, and mix evenly;

[0032] S105: Use the jet mill process to further crush the hydrogen powder into fine powder, and add hydrogen ...

Embodiment 1

[0041] Embodiment 1, it comprises the steps:

[0042] The cerium-iron-boron alloy quick-setting sheet is prepared by the quick-setting process, and its composition and mass percentage are Ce6.5Nd18.4Pr7.1Fe64.6Co1.2Al0.4Cu0.15Ga0.5Nb0.2B0.95;

[0043] Use the hydrogen crushing process to roughly crush the quick-setting tablets to make hydrogen crushing powder;

[0044] Put the hydrogen broken powder into the mixing tank, fill the tank with nitrogen to 0.2Mpa, then fill with 150ppm hydrogen, add an appropriate amount of antioxidant and gasoline into the tank, and mix for 2 hours;

[0045] The mixed hydrogen crushing powder is further crushed by using a jet mill process, the amount of hydrogen added in the jet mill process is 100ppm, and the particle size distribution of the prepared fine powder is 2.1-2.8 microns.

[0046] The jet-milled fine powder is formed by magnetic field orientation, isostatic pressing, vacuum sintering and tempering heat treatment at one time. Wherein,...

Embodiment 2

[0048] In Example 2, a cerium-rich magnet was prepared using the same ingredients as in Example 1 and a similar preparation process, the difference being: (1) Hydrogen gas was not charged during the hydrogen breaking and mixing process; (2) Hydrogen gas was charged during the jet milling process. 250ppm hydrogen. The performance test uses a permanent magnet characteristic performance measuring instrument, and the test temperature is room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com